The Solid Waste Association of North America (SWANA) Applied Research Foundation released a report concluding that: a significant amount of additional food waste processing capacity will be required to achieve national, state, provincial, and local food waste diversion goals. The report also emphasizes the need for local decision-making in selecting and implementing those food waste diversion programs.

…a significant amount of additional food waste processing capacity will be required to achieve national, state, provincial, and local food waste diversion goals. The report also emphasizes the need for local decision-making in selecting and implementing those food waste diversion programs.

The report goes on to say that interest in recovering food waste from municipal solid waste is growing to meet goals established by the U.S. Environmental Protection Agency and U.S. Department of Agriculture, but many major metropolitan areas lack the infrastructure to manage the ability to meet the established goals. Two examples were cited:

Several states, including Massachusetts and Connecticut, condition their food waste diversion requirements on the ability of generators to access adequate capacity within a certain distance.

Speaking as SWANA’s Executive Director and CEO David Biderman stated:

We believe that Americans need to rethink how food is handled before it is considered waste, to divert it into programs to feed people, and to find other productive uses for food as food. Once it becomes waste, however, municipal decision-makers, working with their processing partners, need to determine how to best manage the material.

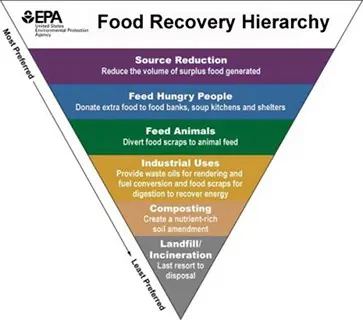

The SWANA report focuses on the effects of food recovery at the two lowest tiers of the hierarchy – composting and landfilling/incineration. The report concludes that food waste diverted from landfill operations has the potential to be processed at composting facilities. Then, going on to say that anaerobic digestion (AD) and co-digestion at wastewater treatment facilities are also likely destinations for diverted food waste.

Jeremy O’Brien, Director of the Applied Research Foundation, noted:

The food recovery hierarchy does not apply universally; an analysis of greenhouse gas impacts based on local data and conditions is needed to identify the best food scraps management options for a specific community.

The report encourages solid waste managers to perform a life cycle analysis of economic and environmental costs and benefits based on local needs, system capabilities, and data to identify the most effective ways to manage food waste at the local level.

SCS Engineers and SWANA are both long-time advocates for local decision-making in establishing programs to collect and manage municipal solid waste.

Related articles:

Operational expenses such as replacing collection vehicles, considering and implementing recycling programs, and the impact of stricter environmental regulatory programs can all affect collection fees and the quality of service. Strategic business planning solves the ongoing process whereby an organization determines where it is going… plus how it will get there, and what tools and resources it will use.

The City of Killeen recently worked with SCS Engineers to create a 20-year master plan with modeling capabilities to determine the optimum scenarios that benefit the surrounding communities and one that helps manage environmental safety and the outlay of capital before the expense of planning, designing, and building begins. Population projections, demographics, cost and historical data, among other resources, make up the information that is then organized and analyzed to prepare projections based on changing scenarios over a period of years. This type of economic study enables the planning team on any proposed project to provide a “what if” analysis for the decision-makers with the potential impact a proposal may have on customer rates and fees.

The collaborative effort between the City and SCS has culminated in a long-term financial roadmap and planning tool, which evaluates the impact of operational expenses and provides a basis for planning capital expenditures. The plan is already in use by the City’s decision-makers to determine the efficiency of investing in equipment and a Material Recovery Facility (MRF) as part of a waste management plan. Key outputs of this study included the justification for the City’s acquiring new collection equipment and further assessment of the feasibility of implementing single-stream recycling.

This type of business analysis requires technical expertise in the many aspects of waste management. You’ve got to dig deep into the conditions that present a financial, environmental, or quality challenge to managing wastes in order to deliver a system that is serviceable for decision-makers to use for many years.

A Florida county conducts a pilot project to gauge its ability to manage yard trimmings

and biosolids using internal resources – and to confirm marketability of the finished

compost.

Read the Biocycle article by Beth Schinella and Bruce Clark

Infrastructure Week (May 16–23) is a national week of events, media coverage, education, and advocacy efforts to bring the state of the nation’s infrastructure to the attention of all Americans. Forester Media, the publisher of MSW Management magazine, is an Infrastructure Week affiliate. John Trotti, MSW Managing Editor recently surveyed Jim Walsh, P.E., BCEE, President and CEO of SCS Engineers and long-time friend of the magazine on the topic. Jim is first out of the blocks to answer the four questions John asked of respondents from MSW and Forester’s other publications, Business Energy, Erosion Control, Grading & Excavation Contractor, Stormwater, and Water Efficiency.

MSW Management (MSW): Which infrastructure projects should be given priority? Roads and bridges? Dams and levees? Water supply? Electrical grid? Waste management?

James Walsh (JW): Typically public safety, cost, and benefit determine the priority for infrastructure projects, and different political jurisdictions have different priorities. Where highways and bridges are new but waste management facilities are old, the priority might be waste management facilities, and vice-versa. Some types of infrastructure are more amenable to private sector solutions, which can allow the government to focus on other types of infrastructure. The trend in waste management, for example, has been to rely on the private sector in the last decade

Each segment faces difficult challenges; the most significant is funding. Waste management does not necessarily have priority over other projects, but has progressed by regionally identifying the infrastructure necessary. Thus, each region avoids the pitfalls of competing for funding with other regions and other projects.

SCS Engineers focuses on waste management, but there are opportunities to interact with other segments in sustainable ways. For instance, we have energy clients who supply coal ash to specialty cement companies who use it to make “green” cements that last longer in applications such as road construction. We design and construct facilities that take the byproduct gases from the decomposition in landfills to generate electricity reducing their dependence on fossil fuels, or directly use the gas for energy to power wastewater plants simultaneously cleaning and conserving water. We find ways to safely redevelop contaminated property supported by existing infrastructure, thus reducing the need to build new infrastructure.

In short, we work toward helping clients find sustainable solutions to infrastructure projects.

MSW: Is there a solution to long-term infrastructure funding?

JW: With respect to the waste management infrastructure, waste systems require significant capital investment in land, equipment, facilities, and infrastructure. While many governments have decided to rely on private industry instead of financing new governmental facilities, others have become much more sophisticated in adopting private sector approaches to financing. Pro-Forma Economic Life-Cycle Models can assist governmental entities to identify the critical variables that can impact the success of an infrastructure project. Moreover, economic models evaluate how various components of a waste system and variable assumptions integrate together into a sensible approach. Pro Forma Economic Models allow for a careful analysis of the life-cycle costs and potential revenue sources and identify factors that will influence the waste system costs and demonstrate how to adequately and equitably fund the system. These Models provide different scenarios and eliminate options that are not financially feasible or do not fit a region’s short- and long-term needs or priorities. Sensitivity analysis can be conducted to understand better the impact these variables have on capital costs, operating expense, and the overall system economics. By assessing the economic and regional benefits first, we can focus on designing and building infrastructure solutions that are safer, longer lasting, and affordable. Other benefits include adjusting the Model if there is a major change in the commodity market, such as plastics’ recycling is experiencing now and when considering the use of new technologies.

Every industry segment and every region have a different blend of socio-political conditions, geography, and monetary resources—we assess and design to their particular needs. Adopting new waste management technologies, such as anaerobic digestion or waste diversion, as part of an overall waste management program can be integrated into the Model to study how, and if, they sensibly integrate within the existing program. New technologies are typically more expensive than mature technologies such as recycling facilities and landfills, but that condition alone is not why they are considered valuable to a region. The framework considers elements key to integrating anaerobic digestion for example into a long-term program. Capital investment, a significant centralized source of high-quality organic waste, power costs and economic utility incentives, limited land suitable for composting, lack of conventional waste-to-energy facilities, or a ban on organics disposal in landfills are some of the considerations.

Many states are developing organics diversion initiatives, discouraging or banning organics from landfills; they will want to develop separate capacity for diversion within their overall program to build a sustainable plan for the long-term. In some states there is plenty of environmentally sound landfill capacity, recycling facilities have adequate capacity, and the socio-political climate has different ideals. What works in Iowa might not be suitable for California.

MSW: What kind of harm is the current state of our infrastructure doing to the economy and the community?

JW: Every four years, the American Society of Civil Engineers releases a “Report Card for America’s Infrastructure” depicting our nation’s infrastructure condition and performance. In a traditional school report card format, individual infrastructure segments are assigned letter grades—solid waste has the highest grade of B- in the most recent report published in 2013. The waste management infrastructure in the United States is robust, diverse, and significantly supports our economy and communities by providing safe and cost-effective management of the materials that we discard on a daily basis.

MSW: What can various government entities—from local to Federal—do to attract private sector support and investment?

JW: In the United States, private solid waste facilities manage 75% of the municipal wastestream. The waste management industry has many examples of public/private partnerships and significant investment by the private sector. Just look at firms like Waste Management Inc., Republic Services Inc., Waste Industries, Waste Connections, WCA Waste Corporation, Covanta, and Wheelabrator, which own and operate numerous landfills, compost facilities, waste-to-energy facilities, transfer stations, processing facilities, alternative technologies, and hauling companies. These facilities require significant private investment. Allowing private industry to participate in the management of waste management infrastructure brings needed fiscal discipline and accountability to the overall waste system infrastructure.

The private sector is attracted to markets that are predictable and that provide an appropriate return on investment. Jurisdictions with a reputation for making sudden unpredicted changes in regulations that adversely affect the return on investment will find it difficult or impossible to attract private sector support.

The waste management sector and SCS Engineers have seen our share of magic technologies that are literally too-good-to-be-true, yet somehow attract governmental support both financial and otherwise. It is fine for government agencies to provide grant support for research related to promising new technologies, but adopting an unproven technology as the sole means of waste management is inviting a public health crisis. Private sector investment is not attracted to jurisdictions that have unrealistic expectations.

About James Walsh, PE, BCEE, President and CEO of SCS Engineers

Jim has worked at the forefront of sustainable waste management for more than 40 years. He has authored numerous publications, technical support documents, presentations for the USEPA, US DOE, the Gas Research Institute while serving the Solid Waste Association of North America (SWANA), National Waste and Recycling Association (NWRA), and the Environmental Research and Education Foundation (EREF), among others.

Taken as a whole, mixed MRFs have operated well since their reincarnation in the early 1990s and continued refinement through today. The sorting technology, which has been evolving for the last 25 years, has been proven to work and is reliable. Complete, pre-engineered integrated systems have been available now for years from a growing selection of established companies dedicated to the solid waste industry that can provide planning, engineering, manufacturing, controls, and startup, whether for new facilities, or retrofits of existing older facilities.

With that said, the following conclusions are offered for consideration:

Contact the authors: Bruce Clark and Marc Rogoff

by Tracie Onstad Bills, Northern California Director, Sustainable Materials Management at SCS Engineers

For many years source separation was the primary method for recycling. However, technology has changed how recyclables are collected and processed. China, the largest importer of materials for recycling now strictly enforces regulations on importing contaminated materials for recycling into the country. China’s Operation Green Fence puts restrictions on what material China will accept, rejecting materials that don’t meet higher standards of cleanliness; that means rejected materials get buried in a landfill instead of being recycled.

Regardless of the type of recycling program, the biggest challenge here at home is now minimizing contaminated recycling material. Communities are struggling to meet diversion goals and provide materials to local recyclers that are free of common contaminants such as liquids left in containers or motor oil. My SCS team has assisted communities in the last few years to address contamination issues and I’d like to share what works best to kick start addressing the issue at home.

Recycling Assessments: Conduct a visual and physical characterization study to identify contamination levels using one of these two methods for the evaluation:

Recycling Technical Assistance: Meet with local businesses and perform a walk-through of their facility to collect baseline waste assessment and material collection infrastructure information. This information can then be used to provide customized recycling and composting recommendations, and implementation support such as employee training sessions, providing signage and collateral, referrals, and multi-lingual outreach services.

Review and Analysis of Community Recycling Programs: Review and analyze your recycling program. An environmental engineer can provide recommendations and assessments on how a recycling program can be enhanced to reduce the quantity of contaminated materials. Services typically include everything from examining outreach materials to the flow of the recycling from generation to transport to processing.

Planning and Implementation of Behavior Change Programs: There is value in providing comprehensive programs and explicit outreach materials for increasing the probability of cleaner recycling. Behavior change programs focus on planning and implementing programs that identify key triggers to encourage action in the community. These programs help communicate the importance and value of specific activities to the community and cross any age and cultural barriers.

Contamination is a global problem and is challenging, but there are steps to minimize the problem in your community.

About Tracie Onstad Bills

Tracie Onstad Bills has been in the Environmental and Resource Material Management Field for over 20 years. Her expertise revolves around commercial recycling technical assistance, environmental purchasing, large venue and event zero waste programs, research and sustainability planning, garbage hauler franchise compliance and review, construction and demolition program / ordinance analysis and writing, climate inventory compilation, research and feasibility studies to help clients with comprehensive waste prevention and zero waste programs. Ms. Bills has a BA in Environmental Science from San Jose State University, is a CRRA Board member and belongs to the SWANA Gold Rush Chapter, National Recycling Coalition and the Northern California Recycling Association. Contact Tracie here.

Learn more on the SCS service pages and read SCS project case studies from across the nation to help fine tune your program:

An SCS pro forma model for waste management gives you the much-needed ability to analyze how different elements of a business plan will impact your cash flows and value. Subsequently, using individual forecasts and operations data, you can analyze when in the future you might need financing allowing you the time to plan to acquire sufficient resources, permits, and equipment. Read the Merced County case study here to learn more.

SCS Engineers assisted the Merced County, California, Regional Waste Management Authority (RWA) in developing a Pro Forma Model that encompasses projected operational costs and revenues to help decision-makers develop timely cash flow forecasts. The RWA now has a useful tool for annual budgeting and developing long-term capital policies.

After several years of revenue declines for numerous reasons, including the recession, a change in management in 2012 ordered a re-assessment of RWA’s operational and administrative functions. Throughout the year-long process, a new Regional Waste Director was selected to implement a progressive strategy that would realize operational efficiencies, cost savings, an expanded customer base, and lower long-term debt through bond refinancing. These measures provided considerable benefit, particularly in regards to the long-term financial health of the agency; however, it was not clear if cash could be generated quickly enough to meet the existing need. As a result, the agency hired a rate consultant in April 2015 to assess the anticipated shortfall and prepare a report to the RWA’s governing board.

The RWA owns and operates two disposal and recycling facilities, each located near the population centers of Merced County. Both landfills need expansions to increase disposal capacity in the coming years. SCS Engineers developed a Pro Forma Model to help the RWA prepare a long-term cash flow analysis and assess whether or not funds were available from operations to forestall a bond issue for the capital improvements as well as to fund adequate emergency reserves. At the beginning of SCS’s engagement, RWA staff provided background data and information concerning residential collection revenues and operating expenses.

The Pro Forma Model estimated annual net revenues during the 12-year planning horizon; determined that the current debt service is a major drain until the bonds mature in FY 2026/27; calculated that funds for projected capital improvements, fleet replacement, and a new “Rainy Day Fund” can be realized even if the RWA receives low waste deliveries to the landfill; and projected cash reserves. The model recommended that the RWA consider funding a landfill gas to energy project out of cash reserves rather than bond proceeds and projected annual revenues from methane sales.

The RWA adopted the findings of the proposed pro forma model in October 2015. Conducting the pro forma modeling effort enabled the RWA’s decision-makers to project costs of the various capital, fleet, and waste flow options. Key among the lessons learned was the implementation of a “Rainy Day Fund” to provide a long-term financial backstop for unforeseen events in landfill operations that cannot be predicted today. Such events could include groundwater and landfill gas remediation, issues with landfill liners, and weather events. The fund is capped at 25 percent of the RWA’s annual operating costs, which can also provide three to four months of operating expenses. While typical of many large County or municipal General Funds, it is less typical of individual enterprise funds in the past. Such Rainy Day Funds are becoming more and more prominent across solid waste agencies in the United States.

Lastly, the RWA now has a financial tool that can be updated annually and will continue to project future revenues and capital expenditures and ultimately forecast rate needs more accurately.

Marc Rogoff, Ph.D., is a Project Director for SCS Engineers’ and our National Expert on Solid Waste Rate Studies. Marc has over 30 years of experience in solid waste management as a public agency manager and consultant and has managed more than 200 consulting assignments across the United States on all facets of solid waste management. He has written and co-authored many articles, including the following:

Conducting Solid Waste Rate Studies and Business Plans

Trends in Solid Waste Collection

Click here for more information about SCS Engineers Solid Waste Services

The Solid Waste Association of North America – SWANA, is the largest member-based solid waste management association in the world.

SCS Engineers proudly announces Nathan Hamm, P.E., is the recently elected President of the Kansas Sunflower SWANA chapter. Members of the chapter voted to elect Hamm to continue the leadership of John Hawk, the former chapter President and the General Manager of the McPherson Area Solid Waste Utility. Hamm’s term began on October 22, 2015, and will run for two years.

Nathan Hamm is a registered professional engineer in Kansas and five surrounding states with nearly two decades of experience in the field of environmental engineering. He is a Vice President at SCS and currently serves as the Overland Park –Kansas City Office Manager. As Office Manager, he is responsible for managing the technical and support personnel and the office’s financial performance and business development efforts. He also manages complex projects, maintains client relationships, and provides technical guidance.

“An environmental solution mandates innovative thinking and broad resources, “stated Hamm. “ Our Kansas SWANA chapter provides these and stays true to our principles; that’s how we remain effective and helpful to our members.”

Hamm’s career has concentrated on environmental solutions in solid waste management, alternative energy, power generation, and in agricultural production industries. He is a skilled leader developing and managing multi-disciplinary teams to achieve critical objectives.

Congratulations Nathan!

Stay informed. Explore a variety of topics and expand your knowledge of what’s happening in solid waste management. Today’s SCS blog covers Safety, Privatization, Anaerobic Digestion, Coal Combustion Residuals in MSWLFs, and the International Climate and Clean Air Coalition.

Click the article or presentation title to read more.

Is Privatization the Answer? You need to consider several factors before making the decision for solid waste services. The decision by a governmental agency to perform solid waste services or to outsource them (privatizing) is complex and should consider costs and the major factors discussed in this MSW Management article by Marc Rogoff, Karl Moyers, Michelle Leonard, and Robert Gardner.

Climate and Clean Air Coalition to Reduce Short-Lived Climate Pollutants (CCAC) SCS will participate in the CCAC’s initiative to mitigate Short-Lived Climate Pollutants (SLCPs) from the Municipal Solid Waste sector. Read more about this international coalition to get involved.

Municipal Solid Waste Landfills and Coal Combustion Residuals Municipal solid waste landfills can safely manage CCR from coal-burning electric utilities, and changing regulations may increase the market for off-site disposal of CCR. But landfills should accept CCR only after adjusting their procedures to reflect the special characteristics of CCR materials. What do you need to know? Find out in this article by Mike McLaughlin member of the ABA, SEER Waste and Resource Recovery Committee.