Join SCS Engineers at Green Technology’s Sustainable Facilities Forum on May 9 at the Scottish Rite Masonic Center in Sacramento, CA.

The conference will highlight strategies, best practices and technologies behind successful public sector facility projects. The event includes access to education sessions, live keynote, annual leadership awards presentations and to the sustainable products and services displays.

The concurrent sessions offer insights from the experts and practitioners at the leading edge of green progress, in fields ranging from transportation and energy to funding, architecture and green schools. Stroll through the exhibit space and discover dozens of green products and services all in one place. Find out what’s new and get an intensive, hands-on education that’s not available anywhere else!

The Forum is designed for public and private sector professionals engaged in facility project design, decarbonization, water conservation, electric vehicle and electric vehicle infrastructure.

Check the conference site for more details and information.

Conducting Phase I Environmental Site Assessments (ESAs) is important to avoid significant financial risks for buyers and lenders. Inexperienced or unqualified consultants might overlook critical issues, making it vital to choose qualified environmental consultants. We recommend interviewing consultants to discuss project needs and assess their expertise to understand how they handle potential challenges.

It is essential to ensure the consultant’s qualifications. This process includes checking their educational background and professional certifications, such as Professional Geologist (PG), Professional Engineer (PE), and Certified Environmental Professional (CEP).

The ASTM International E1527-21 standard, effective in early 2023, is the current industry benchmark for Phase I ESAs. These assessments serve two primary purposes: due diligence — identifying potential contamination in real estate transactions, and liability relief — aiding purchasers in qualifying as bona fide prospective purchasers (BFPPs) to avoid liability for existing contamination.

To gain recognition as a BFPP, compliance with the All-Appropriate Inquiry (AAI) Rule is necessary. A Phase I ESA conforming to the current EPA-approved ASTM standard demonstrates this compliance.

Under Federal Law, the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) holds current property owners liable for environmental contamination in all but limited circumstances, even if the contamination occurred before their ownership. In some states, like New Jersey, claiming the Innocent Purchaser Defense requires additional assessment work.

Risks of Inadequate Phase I ESAs

The case of a financial institution versus an environmental consulting company underscores the risks associated with an inadequate environmental site assessment. The financial institution suffered considerable monetary loss due to an incomplete historical review, which failed to detect signs of contamination. Additionally, the property owner lost both the functional value of their property and the right to legal action against the assessment contractor, as they were not designated as “users” in the environmental report, facing potentially millions in cleanup costs.

A report from the USEPA released three months after the property transaction confirmed radioactive contamination on the site, previously utilized for hazardous material processing. Despite historical cleanup efforts, extensive radioactive contamination remained, with records dating back decades. This contamination significantly devalued the property and increased liabilities for the property owner and the financial institution.

For several months, the property owner delayed informing the financial institution about the contamination and related legal action. A new environmental consultant hired by the property owner estimated remediation costs to be between $4 million and $30 million. The property owner defaulted on their loan from the financial institution 33 months after its initiation, with a remaining balance of $3 million. Subsequently, the financial institution obtained a new appraisal for the property, which indicated an “as is” value of zero dollars.

Key Recommendations:

Risks of Using an Inexperienced Consultant

In the T&K Realty case, the environmental consultant performed a Phase I ESA for T&K Realty but failed to identify an underground storage tank despite evidence of a potential tank location. The consultant installed monitoring wells on the property as part of a Phase II ESA. During sewer line construction, workers found and uncovered a tank. They discovered a monitoring well drilled through the tank, releasing its contents. The tank, located next to a garage that serviced motor homes and other vehicles, contained volatile organic compounds like dichlorobenzene, 1,2-dichloroethene, methylene chloride, trichloroethene, benzene, ethylbenzene, naphthalene, toluene, trimethylbenzene, xylenes, solvents, and petroleum constituents. Complicating matters, the consultant used the sewer contractor to try to remove the tank, resulting in the contractor spilling most of the remaining contents on the ground. The release and subsequent spill resulted in groundwater contamination.

T&K Realty had to pay the costs incurred by NYSDEC, the costs to investigate the contamination and remediate the site, and legal costs. These costs amounted to hundreds of thousands of dollars.

Key Recommendations:

Conducting a Phase I ESA has become customary, but one should never underestimate its value. Collaborating with a qualified and competent Environmental Professional (EP) to ensure compliance with ASTM standards and the AAI Rule is essential. Failure to meet these requirements in a Phase I ESA could jeopardize the purchaser’s liability defenses.

Recognized Environmental Conditions – Best Practices

In the case of TC Rich vs. Shah Chemical Corporation (Shah)[1], an interesting situation arose regarding the recognition of a Recognized Environmental Condition (REC) during two separate Phase I ESAs conducted at separate times.

In the initial Phase I ESA TC Rich performed in 2005, they identified only one REC before purchasing the property and concluded that there was no contamination after soil sampling.

However, in 2015, TC Rich conducted another Phase I ESA to secure a loan. This time, the Phase I ESA identified the prior operations of Shah as a REC and initiated a Phase II ESA. The Phase II ESA revealed Tetrachloroethylene (PCE) contamination in soil, soil gas, groundwater, and even indoor air within the property building, consistent with discharges from Shah’s historical operations.

As a result, TC Rich initiated legal action against Shaw to recover toxic cleanup costs for the property, future cleanup costs, past damages, and attorney fees.

Importantly, TC Rich asserted that they neither caused nor contributed to the hazardous substance discharge on the property and had no prior knowledge or reason to believe that the property was contaminated. TC Rich took civil action against Shah for future cleanup costs and neither caused nor contributed to the contamination, leading to a settlement. If necessary, TC Rich could have used the “innocent landowner” defense under CERCLA.

Key Recommendations:

Conducting thorough Phase I Environmental Site Assessments (ESAs) is essential for uncovering and addressing potential environmental contamination and conditions linked to properties. Inadequate ESAs, often resulting from inexperienced consultants, can have significant financial and legal consequences for the owner, borrower, and/or lender. This is exemplified in various cases, including those detailed herein, which involved a major financial institution, an environmental consulting firm, and situations like T&K Realty and TC Rich.

Compliance with the AAI Rule is an important first step to qualify for the Bona Fide Prospective Purchaser defense under CERCLA, thus helping parties avoid financial liability for contamination caused prior to their ownership.

In summary, compliance with ASTM E1527-21 and the AAI Rule is essential for due diligence efforts to ensure legal protections and the performance of a thorough risk assessment to maintain confidence in real estate transactions, especially in urban and industrial areas with an environmental history.

References:

This protocol applies to greenhouse gas reduction projects that divert eligible organic waste or agro-industrial wastewater streams that otherwise would have gone to uncontrolled anaerobic storage, treatment, and disposal systems (solid waste landfills, onsite anaerobic wastewater treatment facilities, etc.).

Projects that involve co-digestion of eligible organic waste streams with livestock manure are also eligible if they comply with the Livestock Project Protocol, diverting waste to a biogas control system (BCS). The protocol accepts several technologies, including:

Project Eligibility

The protocol stipulates the following requirements:

Project Exclusions

Protocol excludes the following activities:

Project Outcomes

A project is eligible to receive credits for ten years from the start date or until project activity is required by law. Applications for a second 10-year eligibility period are available. Only two AD facilities have registered with the Climate Action Reserve (CAR). CAR has awarded these projects a total of 224,655 CRTs, valued at approximately $700,000. In 2022, CAR awarded 22,257 CRTs to these projects. At a market price of $3.00/CRT, 22,257 CRTs have a value of $66,771.

Credit Feasibility

Understanding the technology and navigating protocol requirements can take time and effort. That’s where we come in. Contact SCS Engineers at or Greg McCarron on LinkedIn to learn how your project may qualify.

Additional Resources

Conducting Phase I Environmental Site Assessments (ESAs) must navigate the complexities of fees versus liability to provide crucial services. Balancing these aspects is essential for mitigating future liabilities while ensuring thorough assessments during due diligence.

Environmental consultants face significant risks during Phase I ESAs. The potential environmental liabilities discovered often exceed the fees and profits from these assessments. Inadequately performed ESAs or overlooked environmental issues have led to substantial financial consequences for firms, sometimes amounting to hundreds of thousands of dollars. This highlights the importance of thoroughness and accuracy in these assessments to mitigate risk and protect the environment, the borrower or lender, and the consulting firm.

According to LightBox EDR’s historical data[1], the average fee for a Phase I ESA rose 11% from 2018 to 2023, with costs ranging between $1,400 and over $7,500. These variations reflect factors like the assessment’s complexity and the property’s characteristics.

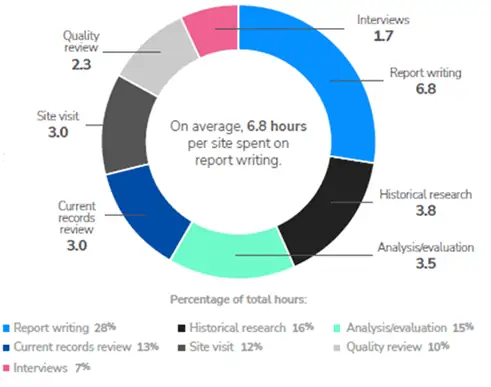

Report writing consumes the most hours in Phase I ESA-related tasks, LightBox EDR reports. The average hours per report across all aspects is twenty-five. A $75/hr. Consultant preparing the report costs $1,875, compared to $150/hr. Consultant at $3,625, not including profit and direct costs like travel, historical research fees, and regulatory fees. Investing more in a comprehensive ESA may be more cost-effective than missing a significant environmental issue.

Choosing a sub-$3,000 consultant for a Phase I ESA, regardless of the property’s apparent simplicity, could increase risks. Even straightforward properties can present unforeseen environmental challenges, affecting assessment accuracy and the project’s timeline and cost.

Firms conducting Phase I ESAs must adhere to professional standards like ASTM E1527-21 or local standards. Failing to meet these standards can lead to liability for missed or inadequately assessed environmental conditions.

The cost of a Phase I ESA reflects the required research and analysis, including a review of historical records, site visits, and potential environmental risk evaluation. Costs vary based on the expertise needed, especially for properties with complex histories or significant environmental issues and legacies.

Despite having professional liability insurance and contractual limitations of liability, firms can face significant business disruptions due to the time and expenses involved in litigation from oversights or inaccuracies in assessments.

Paying more for a Phase I ESA often results in a more comprehensive assessment. Higher fees enable exhaustive research, advanced technology use, and specialist engagement, leading to a thorough understanding of the property’s environmental status.

The fee for a Phase I ESA should align with the property’s specific complexities and risks. Industrial properties or those with hazardous material histories require more intensive assessment and review than simpler sites. However, low-risk sites can also reveal hidden environmental issues during assessments.

For example, a Phase I ESA on a rural property without apparent issues can become complex due to external factors like a neighboring gasoline tank leak. Such situations highlight the need for comprehensive and well-funded assessments to evaluate a property’s environmental status accurately.

The unpredictable nature of environmental risks emphasizes the importance of thorough and adequately funded Phase I ESAs to identify and address such risks effectively.

The implementation of ASTM E1527-21 in February 2023 introduced new considerations. This standard clarifies All Appropriate Inquiries (AAI) requirements and brings more precision to the assessment process. It mandates historical records for industrial properties, specific photographic and mapping requirements, and land title records detailing environmental liens or Activity/Use Limitations.

A notable update in E1527-21 is the approach to emerging contaminants. Until classified as a federal CERCLA hazardous substance, emerging contaminants like PFAS and PCB-containing building materials are optional in Phase I ESAs. This standard evolution reflects the dynamic nature of environmental assessments, where the cost of a Phase I ESA is a strategic decision to mitigate liability risks. Consequently, contaminants like PFAS and PCB-containing building materials, while not mandatory, can be included as a ‘non-scope consideration’ at the discretion of the Phase I ESA user.

While higher costs often lead to more thorough and reliable Phase I ESAs, balancing these costs with the property’s specific needs and risks is vital. The goal is a comprehensive understanding of environmental risks and conditions that support cost-effectiveness.

Investing more in a Phase I ESA is an investment in quality, risk management, and long-term cost-effectiveness, benefiting both the client and the consulting firm.

Phase I Environmental Site Assessments References:

SCS has a group of national experts working with all offices in North America to provide in-depth knowledge based on decades of experience supporting clients’ environmental needs. These resourceful people provide a wealth of information and guidance to support sustainable solutions in the industries SCS works in and with other professionals. Clients depend on the combination of SCS professional expertise, SCS leadership, and our roster of National Experts who consistently bring value to each solution. With the expanded leadership, SCS’s third generation can create even more sustainable solutions to environmental challenges. The firm announces its newest national experts as follows:

Over the years, SCS expanded and hired many talented people. They guide the firm, maintaining the founders’ focus and culture of adopting their clients’ environmental challenges as their own and fostering a culture of success for employees and communities.

The firm has won multiple awards for helping clients minimize waste generation, effectively managing recycling, collection, and disposal operations, renewable energy, safely cleaning up contaminated properties, protecting wastewater and groundwater, and cutting GHG emissions.

These employee-owners are most proud of the difference they make for their clients and communities as trusted partners. SCS clients entrust the firm with managing more than 35 million metric tons of anthropogenic CO2e greenhouse gases yearly. SCS collects and beneficially uses or destroys enough to offset greenhouse gas emissions from 7.4 million passenger cars annually. That’s more than any other environmental firm in North America.

Partial reprint of EPA’s Announcement dated January 11, 2024

WASHINGTON – The U.S. Environmental Protection Agency on Thursday announced a proposal to strengthen Clean Air Act standards for large facilities that burn municipal solid waste. If finalized, the updated standards would reduce emissions of nine pollutants, including smog- and soot-forming sulfur dioxide and nitrogen oxides, by approximately 14,000 tons per year, improving air quality for overburdened communities living near these facilities. These proposed standards reflect current technologies available to control pollution in a cost-effective fashion.

The proposed standards would apply to 57 facilities with 152 units that have the capacity to combust more than 250 tons per day of municipal solid waste. Nearly 4 million Americans live within 3 miles of these large facilities, which are disproportionately located in low-income communities and communities of color.

The proposed standards are based on emission levels achieved by the best controlled and lower-emitting sources, and limit emissions of nine pollutants: particulate matter, sulfur dioxide, hydrogen chloride, nitrogen oxides, carbon monoxide, lead, cadmium, mercury, and dioxins/furans.

The Clean Air Act requires EPA to evaluate these standards every five years in order to take into account developments in pollution control technologies and techniques. EPA last revised these standards in 2006.

After accounting for compliance costs of the rule, EPA estimated the net present value of health benefits from the proposed rule, due to reductions in particulate matter and ozone alone, to be up to $14 billion over 20 years. Reductions of mercury, lead, and other hazardous air pollutants required by the proposal are expected to result in additional unquantified economic and public health benefits.

EPA will accept comment on the proposal for 60 days after publication in the Federal Register. EPA will hold an informational webinar and will announce details on its website shortly.

Additional Resources:

Talk with SCS Engineers professionals at the 2024 Solid Waste Operator Conference on February 21 at the St. Cloud Holiday Inn and Suites in St. Cloud, MN.

The conference is a joint effort of the Minnesota Chapter of the Solid Waste Association of North America (SWANA) and the Air and Waste Management Association’s (AWMA) Upper Midwest Section and is focused on safe and effective operations of solid waste facilities in compliance with all applicable regulations. The conference will also emerging issues affecting the management of these facilities. Topics will include:

Click for more conference details and registration information.

We hope to see you there!

SCS Engineers is participating in the Kennesaw State University’s STEM Job, Internship, Co-Op Fair, February 27-29 at the Marietta, Georgia, campus.

This event is a great opportunity for students to speak with SCS about an internship or career in engineering or STEM.

SCS is an employee-owned, award-winning environmental engineering, consulting, and construction firm with offices nationwide. We are seeking a wide variety of dedicated, hard-working professionals with Science, Technology, Engineering, and Mathematics (STEM) backgrounds.

SCS Engineers is participating in the 2024 K-State Engineering Expo on February 13-15, 2024, at the Engineering Complex.

This event is a great opportunity for students to speak with SCS about an internship or a career in engineering or STEM.

SCS is an employee-owned, award-winning environmental engineering, consulting, and construction firm with offices nationwide. We are seeking a wide variety of dedicated, hard-working professionals with Science, Technology, Engineering, and Mathematics (STEM) backgrounds.

SCS Engineers is participating in Michigan State University’s Big 10 Engineering – Diversity & Inclusion Career Event (Virtual) – 2024 on January 23.

This event is a great opportunity for students to speak with SCS about an engineering or STEM career.

SCS is an employee-owned, award-winning environmental engineering, consulting, and construction firm with offices nationwide. We are seeking a wide variety of dedicated, hard-working professionals with Science, Technology, Engineering, and Mathematics (STEM) backgrounds.