Pressure testing of HDPE pipes takes place at almost every landfill lining system and landfill gas collection system construction project. The pipes must be tested to make sure the fusion welds are intact and are not leaking. When engineers specify pressure testing, they identify the required test pressure, the duration of the test, and the allowable pressure drop at the completion of the test. The test pressure may vary from one pipe application to another. For example, the specified test pressure may be as high as 1.5 to 2 times the maximum service pressure in the pipe for leachate forcemain pipes; whereas for pipes used in landfill gas collection systems, where the pipes are under vacuum, the specified test pressure may be less. Test duration may vary from one hour to a few hours, and the allowable pressure drop may vary from zero to a percentage of the initial pressure.

What is often missing from pressure test specifications is the effect of the ambient temperature variation on the pressure changes within the pipe during the test. If incompressible fluid (e.g., water) is used for pressure testing, pressure changes due to ambient temperature variations are less significant than when compressible fluid (e.g., air) is used.

For incompressible fluids, SCS has developed a mathematical model that enables the engineer or contractor to calculate pressure changes due to ambient temperature variations during the test. The calculated pressure change should be considered when evaluating whether the test results are passing or failing. Increasing ambient temperatures during the test may cause expansion in the pipe, and the expansion causes an additional pressure drop that is not caused by any leak in the welds. On the other hand, decreasing ambient temperatures may cause contraction in the pipe, which increases pressure in the pipe. In this case, a pressure drop due a leak in the weld may not be detected because of a higher pressure created inside the pipe due to pipe contraction. It is recommended that engineers or contractors use the mathematical model to calculate a modified allowable pressure drop by considering the calculated pressure change (positive for pipe expansion or negative for pipe contraction) before the pass/fail assessment is carried out.

Recently during the test period in the field, a pressure drop was experienced that slightly exceeded the specified allowable pressure drop. Field staff reported ambient temperature variation during the two-hour test. When the modified allowable pressure drop was calculated using SCS’s model to account for the ambient temperature variation, the test ended up passing. Note that field documentation is extremely important for assessing the pass/fail results. This becomes even more important when the specified test duration is several hours long and the ambient temperature variation is significant.

Questions? Contact Ali Khatami, PhD, PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering. Dr. Khatami has acquired extensive experience and knowledge in the areas of geology, hydrogeology, hydrology, hydraulics, construction methods, material science, construction quality assurance (CQA), and stability of earth systems. Dr. Khatami has applied this experience in the siting of numerous landfills and the remediation of hazardous waste contaminated sites.

Read more here. Pass/Fail Criterion for HDPE Pipe Pressure Testing Using Incompressible Fluid, in Talking Trash, March 2015

Solid waste agencies are under more pressure these days to provide high-quality waste collection, facility enhancements, and landfill operation services. Coupled with the pressures from ratepayers and local government “lean and mean” initiatives to keep rates and expenses low, has many solid waste agencies struggling. Balancing real cost escalation factors such as rising fuel, material, and labor costs against the push for keeping static rates is challenging. Further, full cost accounting is difficult because agencies often support activities not directly related to normal operations or provide “free services” such as street sweeping or collection and disposal for community events (i.e. fairs, farmers markets, runs for charity, art shows). Allocating shared costs across agencies is complicated and at times inaccurate adding to the agency’s overhead.

The scarcity of reliable data available to benchmark solid waste management operations handicaps timely comparisons among solid waste systems. Benchmarking rates or service fees for collection and disposal is challenging, but not impossible using financial tools now considered critical to focus on an agency’s primary policy and management issues. These tools are the basis for budgeting, cost accounting, financial monitoring and evaluation aimed at recovering sufficient money to cover recurrent operational expenditures of the agency’s services as well as to stock up capital for new investments or extensive maintenance.

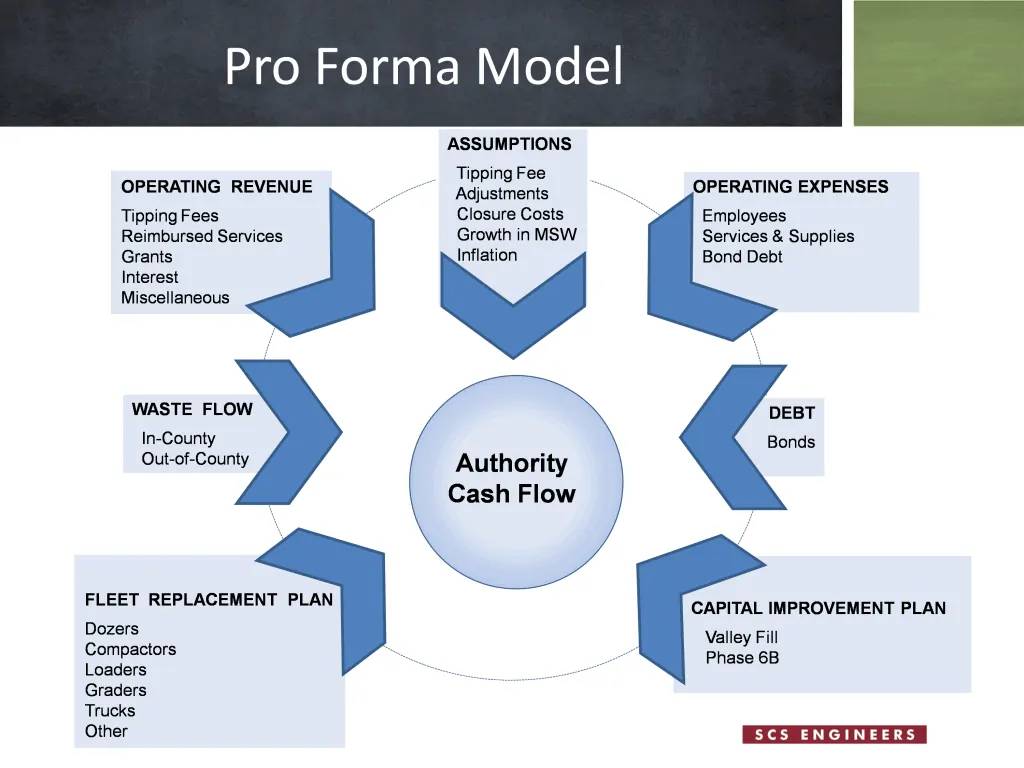

A Pro Forma Model is a financial tool crafted from the market dynamics influencing the life cycle of a specific project, cost center, or program. In the solid waste business, every project is unique, and the design of the pro forma financial model should reflect these differences. To accommodate the various types of business models needed to analyze the feasibility of recycling projects, we’ve developed different types of pro forma models that allow us to tailor the financial statements to the particular project. Thus, each client receives models that have the maximum flexibility to model multiple scenarios of facility size, energy production/co-generation, site locations, and changes in operations.

For example, we have had clients wanting to evaluate the feasibility of a single stream recycling program with multiple cart sizes, evaluate alternative landfill cover systems, and collection equipment and whether or not a change from manual to automated collection made long-term economic sense.

Another client, a private waste hauler, wanted to evaluate the business case for implementation of a leachate evaporator. The cost of leachate disposal was increasing, and our client needed to make a business case for the project. In each of these cases, a pro forma model was developed to help quantify the capital and operating costs of the proposed facilities or programs and then compare these long-term costs against current programs.

The use of financial tools to evaluate the agency’s cost of service is another important area where pro forma modeling is used. Such cost of service studies evaluate the financial aspects of solid waste management programs and remain critical to ensuring sustainability of the agency. In short, these studies show how an agency determines the means to fill the gap between cost and revenues, alert authorities to options of how financial sustainability can be improved, and determine if privatizing some services is a reasonable option.

The lack of specific financial monitoring and analysis of data is one of the significant barriers to being able to sustain any envisioned improvement of an agency system. This concerns budgeting, cost accounting, financial monitoring and evaluation aiming at recovering sufficient money to cover recurrent operational expenditures of the collection service as well as to stock up capital for new investments or significant maintenance. Many agencies do not know the actual cost of providing specific services. Before strategic decisions are made, an important step is to establish a full understanding of the historical or current costs for the provision of the services and the respective revenues. The studies serve to project financial sustainability in the short-term as well as in the long-term.

The growing national trend toward privatization of government-provided services demonstrates that the public sector solid waste agencies must operate efficiently and cost-effectively if they wish to continue providing these services to its citizens. Municipal governmental agencies must optimize the performance of their service utilities to ensure that costs are contained; while at the same time, service levels and customer satisfaction remain high. In fact, it is necessary for public agencies to think and act like the private sector service providers and spearhead efficiency gains and identify cost reduction measures to reduce operating costs while improving customer satisfaction.

In conclusion, the use of financial tools to evaluate current and proposed solid waste programs and facilities is an increasing trend across the nation by many solid waste agencies. These tools provide a useful vehicle for finding optimal management solutions, while at the same time, providing quick answers on their projected financial performance for political decision-makers.

Contact Marc Rogoff, the SCS National Expert on Solid Waste Rate Studies or read more about using financial tools to balance current and future rates while planning for high-quality waste collection, facility enhancements, and landfill operation services.

Economic Feasibility 101 – Understanding the Tools of the Trade, in MSW Management

Solid Waste Planning, City of Killeen, Texas, in Waste Advantage

Regional Waste Management Authority Uses Pro Forma Model for Short and Long-term Operational Excellence and Budgeting, an SCS Blog

Current rates are flat fees where permittees pay approximately $1,800 for a permit whether you have one acre of industrial operations or 100. The proposed rates would consider criteria such as total acres of activity exposed to storm water, permeability, and percent of property used for industrial operations. If you would like to comment directly to the Water Board, email your suggestions to

A panel of experts will convene on Tuesday, March 1, 2016, from 7:30 a.m. to 9:15 a.m. at the Civic Building #8P-Presentation Hall to provide businesses with information necessary to determine if they need to comply or are exempt. The building is located at 10601 Magnolia Avenue in Santee, CA.

Register with Amy Snyder at 1-619-464-1200 or via email at

The session is free and will cover these topics:

Panel of Experts:

Bill Fischbeck, Esq., and the moderator is an attorney in East San Diego County since 1976, Bill’s practice is concentrated in real estate, including transactions and dispute analysis as well as land use matters before public agencies throughout the County.

Cory Jones, P.E., ToR, is a storm water program manager at SCS Engineers. Jones manages complex projects for private and public clients that include site/civil, water/wastewater and storm water engineering. He has completed a wide variety of special studies in storm water management and National Pollutant Discharge Elimination System (NPDES) compliance for federal, state and municipal public agencies.

An Environmental Attorney will also join the panel. The educational session is sponsored by Commercial Properties Group and the San Diego East County Economic Development Council.

Link to more information about storm water management

Dynamic compaction is a construction technique that increases the density of soil/waste deposits by dropping a heavy weight at regular intervals to consolidate and improve the geotechnical characteristics of the deposit so that it can be suitable for redevelopment. This construction technique can be used to transform otherwise undevelopable property, such as old landfill areas, into developable property.

Most soil types can be improved by dynamic compaction; the method is particularly well suited to non-organic, irregular fill, where variable characteristics such as solid wastes are present. Field conditions and several other parameters are considered when designing and implementing dynamic compaction programs to keep costs in line. The primary considerations include, but are not limited to, waste delineation, distance from the ground surface to ground water, waste thickness, minimum energy, and selection of dynamic compaction parameters.

The following factors and associated costs should be evaluated if dynamic compaction is to be considered:

Major change orders and environmental impacts can be expected if the plan does not address these factors.

If you decide to consider dynamic compaction in your redevelopment project, having onsite construction quality assurance monitoring during the process is important. CQA monitoring will verify that the work is implemented as designed and permitted, and that proper techniques are used to make sure the proper distribution of energy into the ground is taking place. The CQA monitor will also check to see that the final configuration of the fill is achieved, a safe working environment is maintained., and that ground vibrations are monitored near adjacent structures to to prevent structural damage.

For developments involving construction of buildings over a dynamically compacted areas, a combustible gas barrier layer is generally required below the building footprint to safely collect and vent subsurface combustible gases (i.e., typically methane) to the environment. Construction costs associated with a combustible gas barrier layer should include the following:

In summary, dynamic compaction is a proven geotechnical construction engineering method that can be used to improve certain landfill areas to support redevelopment. SCS Engineers has completed many projects of this nature and is ready to serve and help to bring your project in service.

Related Article

Pursuing Dynamic Compaction, by Ali Khatami, Ph.D., Bruce Clark, P.E., and Myles Clewner, L.E.P., Waste Age

Sample Case Studies

Environmental Due Diligence – Procacci Site, Sweetwater, Florida

Landfill Engineering and Consulting – Medley Landfill, Miami-Dade County, Florida

Landfill Site Redevelopment for the City of Industry, California

Ali Khatami, PhD, PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering.

Dr. Khatami has acquired extensive experience and knowledge in the areas of geology, hydrogeology, hydrology, hydraulics, construction methods, material science, construction quality assurance (CQA), and stability of earth systems. Dr. Khatami has applied this experience in the siting of numerous landfills and the remediation of hazardous waste contaminated sites.

Dr. Khatami has been involved in the design and permitting of civil/environmental projects such as surface water management systems, drainage structures, municipal solid waste landfills, hazardous solid waste landfills, low-level radioactive waste landfills, leachate and wastewater conveyance and treatment systems. He has also been involved with the design of gas management systems, hazardous waste impoundments, storage tank systems, waste tire processing facilities, composting facilities, material recovery facilities, landfill gas collection and disposal systems, leachate evaporator systems, and liquid impoundment floating covers.

As a designer, I’ve been hired to correct inconsistencies between the gas system and the landfill too many times. Today’s blog is about the most important factors that all landfill gas designers should consider for a gas system to coordinate efficiently with the landfill design as permitted. This is a partial list of best practices developed at SCS Engineers.

Considerations for Design of Gas Collection Systems for Landfills:

1. Include the final cover layers in the gas design details where gas wells are installed near the landfill final surface. This inclusion will help the designer to specify proper heights for gas wells, proper depths for gas headers and lateral pipes, and proper heights for condensate sumps within the lined area of the landfill. Otherwise, locations of these elements may end up being in conflict with the location of various layers of the final cover system to be constructed later.

2. Always leave pipes exiting the liner boundary at the perimeter of the landfill at least 1 ft above the anchor trench shoulder. When the final cover is installed, it would be impossible to install a geomembrane boot over at the cover geomembrane penetration point of a pipe that is in contact with the bottom lining system geosynthetics over the anchor trench shoulder.

3. If flow control valves are located below the final cover near the perimeter of the landfill, design a vertical casing around the valve tall enough that future final cover can be booted to the vertical casing and access to the valve would be possible. Do not use corrugated material as casing because it would be difficult to place a geomembrane boot over corrugated casings. The designer should require sealing the void inside the casing pipe to prevent landfill gas release or oxygen intake through the void. If the control valve is located above the final cover, the designer should specify a proper height for the casing pipe that access to the valve stay above the final cover surface.

4. Locating flow control valves near the landfill perimeter and within the lined area should be in consideration with the future location of a rainwater toe drain system at the toe of the slope that will be constructed when the final cover is constructed.

5. Condensate sumps installed before construction of the final cover should be tall enough to accommodate construction of the final cover system around the condensate sump with sufficient space to boot the final cover geomembrane to the exterior walls of the condensate sump. Miscellaneous stub outs on the condensate sump should be designed in consideration of having enough space for the geomembrane boot in the future.

6. Pipes connected to a condensate sump (such as compressed air line, discharge force main, power conduits, etc.) should be positioned such that boots can be placed on each line at the penetration point of the pipe through the final cover geomembrane. Boots may not be placed on pipes clustered together. If boots are placed on a pipe cluster, the designer should require sealing the voids between the pipes within the boot to prevent landfill gas release or oxygen intake through the voids.

7. Gas pipes located above the final cover geomembrane and crossing terraces on landfill side slopes may create conflict with rain water toe drain at the terrace. The designer should design terrace crossings such that future conflicts can be avoided.

8. Gas pipes crossing an access road on the landfill slope may cause conflict with a ditch adjacent to the access road at the final cover surface. Location of the gas pipes, either below or above the final cover geomembrane, should be designed in consideration of the final cover features that will exist in the crossing area in the future.

9. Gas pipes located above the final cover geomembrane and crossing an access road on the landfill slope may cause a conflict with a rainwater toe drain system above the final cover geomembrane running parallel to the access road at the toe of the slope next to the access road.

10. Gas pipes located above the final cover geomembrane and crossing the access road on the landfill slope may cause road grade problems at the final surface. Specific depressions across the access road width may have to be designed for larger pipes to prevent grades problem at the finish surface.

11. Gas pipes located above the final cover geomembrane may cause conflict with storm water downchutes that will be installed above the final cover geomembrane. Special depressions may have to be designed to place downchutes below gas pipes on the slope. Placing gas pipes above downchute may cause a problem with the flow of condensate in the line.

12. Sometimes horizontal gas collection pipes come out of the landfill side slopes and extend down the slope to a gas header or some other component of the gas system. If the pipe segment on the slope is going to be below the final cover geomembrane, then it must be placed deeply enough in the waste that it would not have any conflict with the final cover system components, such as leachate toe drain systems, terraces, access road ditches, etc. If the pipe segment is going to be above the final cover geomembrane, extension of the horizontal pipe connecting to the pipe segment on the slope will be designed such that the horizontal pipe can penetrate the final cover geomembrane and extend down the slope while located above the final cover geomembrane. Extension of the pipe on the slope above the final cover geomembrane should not cause any conflict with the final cover components, such as rainwater toe drains at terraces or at the toe of the slope next to the perimeter berm, downchute pipes, terrace or access road grades, etc. The elbow at the connection of the horizontal pipe to the pipe segment on the slope and above the cover geomembrane is critical because a geomembrane boot must be installed at the penetration point.

13. If tack-on swales are used on the landfill slopes, gas pipes on top of the final cover geomembrane may cause conflict with the flow line inside the tack-on swales. Large headers should cross tack-on swales at the high-end point of adjacent swales to prevent flow problems in the swale.

14. If tack-on swales are used, the location of wells for drilling purposes should be chosen to be outside the tack-on swale structure.

15. If a gas header located above the final cover geomembrane and crossing a terrace or access road where the terrace or access road is sloping toward the landfill, condensate flow through the gas header may become an issue. Special depressions across the terrace or access road may need to be designed such that condensate can flow in the proper direction.

SCS Engineers is a leader in the design of landfill gas and landfill lining and final cover systems. We evaluate these issues and many others during our landfill gas design work; our clients pay only once for construction of the system and do not have to spend additional money in the future to fix a system that could have been constructed correctly in the first place. Learn more here.

Dr. Khatami has acquired extensive experience and knowledge in the areas of geology, hydrogeology, hydrology, hydraulics, construction methods, material science, construction quality assurance (CQA), and stability of earth systems. Dr. Khatami has applied this experience in the siting of numerous landfills and the remediation of hazardous waste contaminated sites.

Dr. Khatami has been involved with the design of gas management systems, hazardous waste impoundments, storage tank systems, waste tire processing facilities, composting facilities, material recovery facilities, landfill gas collection and disposal systems, leachate evaporator systems, and liquid impoundment floating covers. He has also been involved in the design and permitting of civil/environmental projects such as surface water management systems, drainage structures, municipal solid waste landfills, hazardous solid waste landfills, low-level radioactive waste landfills, leachate and wastewater conveyance and treatment systems.

Contact Dr. Khatami directly to answer questions and comments.

The National Waste & Recycling Association (NWRA) and the Solid Waste Association of North America (SWANA) returned comments and recommendations on the Environmental Protection Agency’s (EPA) draft Part 71 Operating Permit for Ocean County Landfill and MRPC Holdings LFGTE Operations, Permit Number: P71-0CMH-001 (Draft Permit) to EPA Region 2 Permitting Section, Air Programs Branch. The letter was sent on January 28, 2016, to Mr. Steven C. Riva of the EPA.

NWRA and SWANA expressed concerned that the EPA’s issuance of the Draft Permit, and the circumstances under which it has been prepared, represent a significant departure from practical permitting policies and will constitute a disincentive to expand existing and develop future landfill gas-to-energy (LFGTE) projects around the country.

The jointly submitted comments from both not-for-profit Associations on the Draft Permit were intended to convey their members’ strong interest in these projects, which represent an economic investment in alternative renewable energy sources and the reduction in greenhouse gas (GHG) emissions. Both Groups have expressed concern that the EPA’s actions should not undermine those investments and the benefits derived from these LFGTE projects.

The main points of the letter cover the Associations’ disagreement with the EPA’s approach to common control. NWRA and SWANA support the position that the OCL and MRPC are two separate sources that are not under common control, and they oppose the position proposed by EPA Region 2 in the Draft Permit. Both Groups are urging EPA to re-evaluate this decision and utilize an environmentally beneficial approach when making common control determinations for landfills and third-party LFGTE plants both now and in the future. Other portions of the letter address the uncertainty that EPA’s position would create for affected facilities and how it could re-open already settled compliance expectations.

Members of NWRA and SWANA have access to the letter and may continue directing comments and questions through either Association.

Questions directed to SCS Engineers should be addressed to Pat Sullivan, Senior Vice President and the SCS National Expert on the Clean Air Act.

Learn more about SCS Clean Air Act Services, or Greenhouse Gas Services, or

Landfill Gas to Energy Services

SCS Engineers along with Waste Management, Republic Services, Advanced Disposal, National Waste & Recycling Association, Solid Waste Association of North America, The Sanitation Districts of the County of Los Angeles, and other consultants have submitted additional comments to the U.S. Environmental Protection Agency (USEPA), Fuels & Incineration Group, Sector Policies and Programs Division regarding the Supplemental Proposal for the New Standards of Performance (NSPS) for Municipal Solid Waste (MSW) Landfills and the Proposed Emission Guidelines (EG).

The USEPA solicits comments from industry, state officials and other organizations to clarify key points in proposed policy prior to enacting the policy. Although the Agency is not required to consider additional comments after the closing period for such comments, these solid waste industry participants wanted to provide additional findings supporting portions of the policies and guidelines and asking for clarification in areas where there appears to be inconsistency with other federal rules or a lack of data.

The eighteen-page letter was submitted on January 22, 2016, to Ms. Hillary Ward. Since last Friday inclement weather has forced a closing of Federal Agencies in the Washington, D.C. region.

Click for SCS Engineers compliance information.

Click to contact Pat Sullivan, SCS National Expert on EPA Landfill Clean Air Act; NSPS/EG

by Tracie Onstad Bills, Northern California Director, Sustainable Materials Management at SCS Engineers

For many years source separation was the primary method for recycling. However, technology has changed how recyclables are collected and processed. China, the largest importer of materials for recycling now strictly enforces regulations on importing contaminated materials for recycling into the country. China’s Operation Green Fence puts restrictions on what material China will accept, rejecting materials that don’t meet higher standards of cleanliness; that means rejected materials get buried in a landfill instead of being recycled.

Regardless of the type of recycling program, the biggest challenge here at home is now minimizing contaminated recycling material. Communities are struggling to meet diversion goals and provide materials to local recyclers that are free of common contaminants such as liquids left in containers or motor oil. My SCS team has assisted communities in the last few years to address contamination issues and I’d like to share what works best to kick start addressing the issue at home.

Recycling Assessments: Conduct a visual and physical characterization study to identify contamination levels using one of these two methods for the evaluation:

Recycling Technical Assistance: Meet with local businesses and perform a walk-through of their facility to collect baseline waste assessment and material collection infrastructure information. This information can then be used to provide customized recycling and composting recommendations, and implementation support such as employee training sessions, providing signage and collateral, referrals, and multi-lingual outreach services.

Review and Analysis of Community Recycling Programs: Review and analyze your recycling program. An environmental engineer can provide recommendations and assessments on how a recycling program can be enhanced to reduce the quantity of contaminated materials. Services typically include everything from examining outreach materials to the flow of the recycling from generation to transport to processing.

Planning and Implementation of Behavior Change Programs: There is value in providing comprehensive programs and explicit outreach materials for increasing the probability of cleaner recycling. Behavior change programs focus on planning and implementing programs that identify key triggers to encourage action in the community. These programs help communicate the importance and value of specific activities to the community and cross any age and cultural barriers.

Contamination is a global problem and is challenging, but there are steps to minimize the problem in your community.

About Tracie Onstad Bills

Tracie Onstad Bills has been in the Environmental and Resource Material Management Field for over 20 years. Her expertise revolves around commercial recycling technical assistance, environmental purchasing, large venue and event zero waste programs, research and sustainability planning, garbage hauler franchise compliance and review, construction and demolition program / ordinance analysis and writing, climate inventory compilation, research and feasibility studies to help clients with comprehensive waste prevention and zero waste programs. Ms. Bills has a BA in Environmental Science from San Jose State University, is a CRRA Board member and belongs to the SWANA Gold Rush Chapter, National Recycling Coalition and the Northern California Recycling Association. Contact Tracie here.

Learn more on the SCS service pages and read SCS project case studies from across the nation to help fine tune your program:

Have you ever found in the sleeve or the pocket of a new shirt the “Inspected By…” piece of paper? You probably don’t think twice about it. You simply look at it and throw it away. However, if you were to think about it, what might the process be to inspect the garment? To be sure the sleeves are the same length, or the collar is sewn on correctly, or that it has all the buttons. That tag is intended to signify that the product was reviewed and has met its required standards to be placed in service.

Ever wonder if anybody reviews the bottom of a landfill? When is it ready to be placed in service?

When I was a kid, a landfill was, for the most part, a hole in the ground filled with trash. Well, we still dig a hole, but since the early 1990’s, municipal solid waste landfills (MSWLF) require a containment system on the bottom and sides of the landfill beneath the waste. These containment systems, i.e. liner systems, are designed to protect human health and the environment by serving as a barrier between the waste and liquid in the landfill from the soil and groundwater outside the landfill. These liner systems are typically constructed of compacted clay liners and geosynthetic materials which are documented and inspected to ensure the liner system was built in accordance with the permit requirements and its overall purpose of protecting the environment.

The landfill liner inspection process is usually called Construction Quality Assurance (CQA) and is an important and integral component of protecting the environment. CQA is generally performed by a third party firm to provide an unbiased evaluation of the liner construction independent of the owner or the contractor.

SCS provides Landfill CQA services across the country. We have proven, experienced field staff that observe, document and test specific physical properties of the soil liner and geosynthetics. Our engineers are experienced and licensed to certify that the liner was built in accordance with the permit requirements.

Landfill CQA is not limited to the liner system. SCS provided CQA for final cover systems, leachate forcemain systems, and methane extraction systems.

If you are wondering more about landfill CQA or have a need for your facility, give us a call. We’d be happy to discuss in more detail and assist with your project. SCS is ready to serve, and help to bring your project in service.

Learn more about Jeff Reed and Construction Quality Assurance services at SCS, or see a matrix of CQA projects completed.

Contact Jeff Reed

Meet Chuck Pryatel, the newly appointed Industrial Environmental Association (IEA) Secretary.

Chuck Pryatel is a Senior Project Advisor for SCS Engineers with over 30 years of experience in environmental regulatory compliance. He manages projects that include hazardous materials and waste compliance audits, preparation of spill prevention control and countermeasure plans, hazardous waste tank system assessments and certifications, and assists as a regulatory liaison resolving complex environmental issues. His experience includes completing environmental site assessments, subsurface investigations, preliminary endangerment assessments, health risk assessments, and environmental mitigation and clean-ups.

Prior to his private sector work Chuck served in positions of leadership at the County of San Diego Department of Environmental Health including Chief of the Hazardous Materials Division and Chief of the Site Assessment and Mitigation Division.

Chuck has a Masters of Business Administration from San Diego State University and a Bachelors of Arts in Biology from the University of California San Diego. He is a Registered Environmental Health Specialist in the State of California.

Congratulations Chuck!

The Industrial Environmental Association was formed in 1983 to promote responsible, cost-effective environmental laws and regulations, facilitate environmental compliance among member companies and provide related education activities for the community at large. The IEA’s evolution, however, has included an expanding role as the “voice” for manufacturing and associated companies in San Diego and Southern California, not only on legislative matters but on a variety of environmental issues that affect the quality of life of businesses in the region.

The Industrial Environmental Association actively insists on strong environmental compliance efforts among member companies as a matter of written policy. The IEA organizes a number of educational opportunities for member companies and the greater community including information exchanges, technical workshops, written papers, committees, and an annual conference.

IEA activism aims to prove with deeds as well as words that industrial companies care about the community, both environmentally and economically. IEA believes that industry must be involved in the process of environmental policy-making, and urges reliance on scientific, analytical data to evaluate regulations. The IEA willingly works closely with city and county government officials in an effort to realize environmental and community health protection.