Construction and Demolition Recycling Inc. is a California state certified C&D recycling facility which handles debris from the renovation, construction, and demolition of commercial interior spaces. CDR is the only facility in California that accepts only commercial interior debris, and the only facility in the country that can show a better than 80% diversion rate of these materials traditionally buried in landfills.

CDR’s staff also salvages usable items such as furniture, desks, chairs, file cabinets, and more, for reuse, donating more than 50 tons of these materials every month to not-for-profit agencies and other organizations. All of this allows CDR to divert over 80% of all inbound debris from landfills, a diversion rate that has been third party-verified by the Recycling Certification Institute.

The CDR facility in South Gate, California is a fully permitted C&D/inert debris processing and transfer facility. The facility is owned and operated by Interior Removal Specialist, Inc. (IRS), a demolition company that conducts demolition activities primarily of the interior of offices and other commercial buildings. Construction and Demolition Recycling Incorporated’s goal is to lead by example; showing that the diversion of tenant improvement demolition debris can be accomplished as efficiently and cost effectively as the debris from more traditionally recognized demolition debris. CDR has become the first and so far only recycling facility in Southern California that has earned Third Party Diversion Certification from The Recycling Certification Institute, making CDR the only facility in Southern California that is eligible to provide the US Green Building Council LEED Pilot Point for facilities with 3rd party verification.

Read the full article to learn some of the innovative strategies of this successful recycling company in “Construction and Demolition Debris Recycling Program; How CDR was Conceived and How CDR Remains Sustainable.”

Solid Waste Management, Sustainability, and Recycling Programs

By following the simple procedures governing selective routing in the commercial space, it is possible to turn a high disposal garbage collection system into a high diversion recycling system, without incurring additional costs or losing collection revenue. Read more…

Tracie Onstad Bills of SCS Engineers and Richard Gertman of For Sustainability Too explain the steps for commercial-stream routing and management of commercial recyclables with remarkable results in their Resource Recycling article published in June 2016.

Questions? Ask Tracie, she writes a blog series about recycling.

Tracie Onstad Bills, Northern California Director, Sustainable Materials Management at SCS Engineers

Thank you for the responses and questions about my blog Minimizing Contamination in Recycling. It seems appropriate to provide answers to the most frequently asked questions and send more advice. Any program should be tailored to your current collection system; what works and what doesn’t work for your locality; the demographics of your community; and how your community views recycling.

In light of those considerations, here are some recommendations for ways to minimize contamination in recyclables:

Learn more about recycling programs by reading Success In Selective Routing – Resource Recycling or the SCS project and case studies below:

As always, feel free to send me your questions and comments. Contact Tracie here.

SCS Engineers’ Tracie Onstad Bills and Leslie Lukacs were both selected to receive the California Resource Recovery Association’s (CRRA) prestigious Service Award this year. According to CRRA Executive Director, John H. Dane, the award recognizes “exceptional individual service to the organization and a contribution of time or resources beyond expectations.” That sounds like an SCSer alright.

Tracie Bills is SCS’s Sustainable Materials Management Director and is based in our Pleasanton, CA, location. She has been on the CRRA board for 10 years and has served in several leadership positions within the organization, including as its President for three years. Her expertise revolves around commercial recycling technical assistance, environmental purchasing, large venue and event zero waste programs, research and sustainability planning, garbage hauler franchise compliance and review, construction and demolition program / ordinance analysis and writing, climate inventory compilation, research and feasibility studies to help clients with comprehensive waste prevention and zero waste programs.

Leslie Lukacs serves as a Sustainable Materials Management Specialist in our Santa Rosa, CA, office. She has been on the CRRA board for 12 years and also served in a variety of leadership positions. She also founded CRRA’s Green Initiatives for Venues and Events technical council and was an instructor for CRRA’s Resource Management Certification Program for 5 years. Leslie specializes in the design and implementation of sustainable materials management and zero waste programs and is a pioneer in the greening of venues and events throughout the nation. Her extensive expertise in the logistics of zero waste, recycling, and composting programs, such as outreach management, business assistance, master planning, waste audits and characterization studies, extended producer responsibility ordinance preparation and implementation, compliance, grant writing, and administration are all key to successful long-term programs.

Both women were selected by the CRRA Board of Directors to be the 2016 recipients of the Service Award. The awards will be presented at the organization’s Annual Conference Awards Ceremony on August 9 in Sacramento.

CRRA is California’s statewide recycling association. It is the oldest and one of the largest non-profit recycling organizations in the U.S. CRRA is dedicated to achieving environmental sustainability in and beyond the state through Zero Waste strategies including product stewardship, waste prevention, reuse, recycling and composting. The organization provides its members with resources to advance local, regional and statewide waste reduction efforts which result in critical environmental and climate protection outcomes. Members represent all aspects of California’s reduce-reuse-recycle-compost economy and work for cities, counties, municipal districts, and businesses as well as hauling companies, material processors, non-profit organizations, state agencies, and allied professionals.

This innovative sustainable materials management approach involves strategically picking up loads from businesses that generate similar types of discards. The linked article discusses the approach of following simple procedures governing selective routing in the commercial space.

Using a phased methodology, it is possible to turn a high-disposal garbage collection system into a high-diversion recycling system, without incurring additional costs or losing collection revenue. Dumpsters behind shopping plazas and other sites can become opportunities at the center of a thriving materials recovery program.

About the Authors:

Richard Gertman is the owner of For Sustainability Too in San Jose, CA.

Tracie Onstad Bills has been in the Environmental and Resource Material Management Field for over 20 years. Her expertise revolves around commercial recycling technical assistance, environmental purchasing, large venue and event zero waste programs, research and sustainability planning, garbage hauler franchise compliance and review, construction and demolition program / ordinance analysis and writing, climate inventory compilation, research and feasibility studies to help clients with comprehensive waste prevention and zero waste programs. Ms. Bills has a BA in Environmental Science from San Jose State University, is a CRRA Board member and belongs to the SWANA Gold Rush Chapter, National Recycling Coalition and the Northern California Recycling Association. Contact Tracie here.

“Our clients enable SCS to build, grow, and sustain an engineering firm dedicated to solving environmental challenges,” said Jim Walsh, President and CEO of SCS. “We sincerely thank our friends, colleagues and, in particular, our clients for helping us achieve a highly regarded ranking each year.”

Firms are ranked in terms of revenue by Engineering News-Record magazine (ENR), as reported in the May 2, 2016, issue of the “ENR Top 500 Design Firms Sourcebook.” SCS has made the Top 500 list since its publication in 2002 and has ranked in the top 100 of that list since 2008.

When sorted by firm type, SCS Engineers is ranked the second largest environmental engineering firm (ENV) and is ranked in the “Top 20 Sewerage and Solid Waste” service firms in the nation. SCS has made this top 20 list since 2002.

Later in the year, ENR will publish additional resources and lists, including the “Top 200 Environmental Firms” issue, typically published in the month of August.

Learn more about our latest innovation, SCSeTools

The Solid Waste Association of North America (SWANA) Applied Research Foundation released a report concluding that: a significant amount of additional food waste processing capacity will be required to achieve national, state, provincial, and local food waste diversion goals. The report also emphasizes the need for local decision-making in selecting and implementing those food waste diversion programs.

…a significant amount of additional food waste processing capacity will be required to achieve national, state, provincial, and local food waste diversion goals. The report also emphasizes the need for local decision-making in selecting and implementing those food waste diversion programs.

The report goes on to say that interest in recovering food waste from municipal solid waste is growing to meet goals established by the U.S. Environmental Protection Agency and U.S. Department of Agriculture, but many major metropolitan areas lack the infrastructure to manage the ability to meet the established goals. Two examples were cited:

Several states, including Massachusetts and Connecticut, condition their food waste diversion requirements on the ability of generators to access adequate capacity within a certain distance.

Speaking as SWANA’s Executive Director and CEO David Biderman stated:

We believe that Americans need to rethink how food is handled before it is considered waste, to divert it into programs to feed people, and to find other productive uses for food as food. Once it becomes waste, however, municipal decision-makers, working with their processing partners, need to determine how to best manage the material.

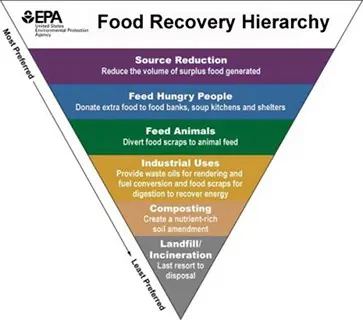

The SWANA report focuses on the effects of food recovery at the two lowest tiers of the hierarchy – composting and landfilling/incineration. The report concludes that food waste diverted from landfill operations has the potential to be processed at composting facilities. Then, going on to say that anaerobic digestion (AD) and co-digestion at wastewater treatment facilities are also likely destinations for diverted food waste.

Jeremy O’Brien, Director of the Applied Research Foundation, noted:

The food recovery hierarchy does not apply universally; an analysis of greenhouse gas impacts based on local data and conditions is needed to identify the best food scraps management options for a specific community.

The report encourages solid waste managers to perform a life cycle analysis of economic and environmental costs and benefits based on local needs, system capabilities, and data to identify the most effective ways to manage food waste at the local level.

SCS Engineers and SWANA are both long-time advocates for local decision-making in establishing programs to collect and manage municipal solid waste.

Related articles:

A Florida county conducts a pilot project to gauge its ability to manage yard trimmings

and biosolids using internal resources – and to confirm marketability of the finished

compost.

Read the Biocycle article by Beth Schinella and Bruce Clark

Taken as a whole, mixed MRFs have operated well since their reincarnation in the early 1990s and continued refinement through today. The sorting technology, which has been evolving for the last 25 years, has been proven to work and is reliable. Complete, pre-engineered integrated systems have been available now for years from a growing selection of established companies dedicated to the solid waste industry that can provide planning, engineering, manufacturing, controls, and startup, whether for new facilities, or retrofits of existing older facilities.

With that said, the following conclusions are offered for consideration:

Contact the authors: Bruce Clark and Marc Rogoff

Subjects: Post landfill use/ life expectancy/plastic grocery bags

Questions:

Hello, I am just looking for a little information about landfills and am hoping that someone in your organization can help me out. This is what’s going on here in my region. Some local citizens along with the Sierra Club are pushing for a ban on the plastic grocery bags used by most grocery stores. A local survey found 80% against such a ban and 20% in favor.

Anyway, one of the supposed reasons for such a ban is that the plastic bags do not decompose in a landfill and essentially last forever. My response is–so what? As long as it is in a landfill there are lots of other things that will be there forever also. Isn’t that what a landfill is for?

I am a little familiar with the construction of a modern landfill, a good thick bottom liner, drains for liquids accumulation, gas vents, a good capping method, etc. All the modern stuff I am sure you guys are good at; when I was young, it was just dirt on the bottom and the top.

I am just not sure what is supposed to happen to the contents of the landfill over a period of time after it is closed, 50, 100, 500 years. Maybe you could give me some input. Also, what does society do with a completed landfill to put the area back to use after it is full, covered up and growing grass? Is it ever expected to be drilled or dug into for construction purposes?

I would really appreciate a response from you guys, even though you probably have lots bigger fish to fry.

Answers:

Thanks for your note, and for your interest in SCS Engineers. Bans on plastic bags and similar strategies such as taxing their use have been adopted by several communities, and the subject is controversial.

Personally, the best argument we’ve heard in support of trying to restrict the use of plastic bags is that the bags too often turn up along highways and waterways in the form of litter. Birds and other wildlife can become ensnared in the bags, and they can remain unsightly for a long time (unlike paper bags).

Now to your questions; our general opinion is that our goals for solid waste management are first and foremost to protect human health and the environment. If we can avoid throwing something like a plastic bag away, or if we can reuse the plastic bag for some other purpose, or if we can recycle the plastic bag, those are preferred to disposal.

If the plastic bags need to be disposed of, a modern landfill or solid waste-to-energy facility are safe and environmentally responsible means of disposal. As you say, a plastic bag might linger in a landfill for centuries, but the bags make up a small percentage of the volume of the solid waste disposed of in modern landfills.

Eventually, landfills can be redeveloped for other purposes, and many older landfills have been redeveloped. Organic materials in the landfill will decompose over time, but a substantial portion of the disposed waste material will remain, perhaps including small volumes of plastic bags. In my opinion, plastic bags in a landfill do not present a threat to human health or the environment.

Thanks again for contacting SCS Engineers.

Additional Information and Resources:

The Washington Post has had several articles and blog postings on the subject over the last few years:

Bag Fees — Declining Use of Bags

Plastic Bag Lobby — San Francisco Ban