See SCS Engineers Odor Management Services

One of the unique aspects of SCS Engineers’ environmental services is our holistic approach to odor management for plant touching facilities. We understand that addressing minor sources of odor can lead to significant improvements in overall air quality. SCS solutions focus on chemical and physical controls and operational changes that can provide stable and reliable odor emissions abatement.

SCS’s commitment to environmental responsibility is evident in our work. Our engineers and scientists employ state-of-the-art technologies to assess odor issues from plant touching businesses and design cost-effective plans to mitigate off-site odor impacts, improving the air quality of nearby communities. These solutions are attractive to plant touching commercial cannabis operations and greenhouses that cultivate, manufacture, and transport cannabis.

Solutions for controlling the advent of odors and mitigating them stem from solutions useful in other facilities, including landfills, composting facilities, food processing plants, and wastewater treatment plants. The SCS Engineers’ approach, building on the success of these operations, utilizes specialized tools and field-proven technologies that determine the specific odor footprint of a particular facility or greenhouse. Collecting continuous measurements and using data enables the assessment of concentrations in real-time and multiple locations and sources within a facility. This method determines relative odor levels and spatial/temporal fluctuations in odor-causing emissions. Using these data and measurements, the team builds a plan to control and mitigate impacts, creating tailored solutions that address them more effectively and for the long term, which is cost-conscious.

At the 2023 Cannabis Conference, SCS engaged with municipalities, cannabis producers, dispensary operators, and technical firms to discuss the application of these technologies within the cannabis industry. Our odor monitoring and management expertise aligns perfectly with the industry’s need for responsible and sustainable practices. Odor control also comes with secondary benefits, such as improving cultivation yield, reducing mold impacts, and improving indoor air quality.

Additional Resources:

Odor attribution is a complicated process when nuisance odors are intermittent and come from more than one source. Today’s blog discusses technological advances in olfactometers and processes to investigate and resolve industrial or agricultural odors.

To investigate odors, SCS begins by reviewing odor complaints for patterns based on location, time of day, the month of the year, and local wind conditions. We then use a site survey to identify candidate sources of odor that may contribute to the region’s odor complaints. Next, we assess the relative contributions of the most probable sources identified by collecting odor samples at/near each source and upwind, downwind, and crosswind. Traditionally, a limited number of odor samples could be collected daily in Tedlar® bags and shipped overnight to a certified laboratory for analysis by an odor panel. The odor panel uses an olfactometer to sniff air samples at varying dilutions for odor concentration, character, and intensity following American Society for Testing and Materials (ASTM) methods.

In certain situations, however, using a portable olfactometer in the field is more efficient. SCS recently implemented the Scentroid SS400 Six Station Portable Olfactometer Odor Lab for large odor studies. The Scentroid SS400 is the world’s only portable six (6) panel olfactometer compliant with European Standard EN 13725/2003 and ASTM E679-04 and is compact for easy transportation and deployment in remote locations. The Scentroid SS400 allows us to:

By having more data, our SCS professionals gain insight into complex nuisance odors and propose targeted mitigation measures that reduce odor concentrations downwind. With over 30 years of experience resolving odors from landfills, wastewater treatment plants, composting facilities, agricultural and manufacturing facilities, we’re confident we can help your facility come up smelling like roses too.

Additional Resources:

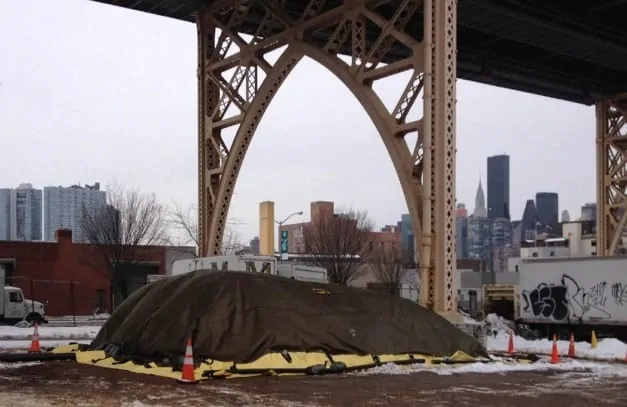

The 2020 Compost Awards recipients, nominated by peers were honored this year at COMPOST 2021, the USCC’s virtual conference. The 2020 Small-Scale Compost Manufacturer Award, given to facilities producing 10,000 tons or less, was awarded to Big Reuse, New York City Compost Project. Big Reuse operates two community composting facilities in NYC, one in Brooklyn and the other in Queens. Big Reuse redeveloped a garbage-strewn lot into an effective facility beneath the Queensboro Bridge on NYC Parks land. Big Reuse works with the New York City Department of Sanitation, community organizations, and NYC Parks to collect food scraps and leaves for composting. Big Reuse composts 2 million pounds annually.

Outside of work, Greg is the Compost Team Leader for a community garden in Bergen County, New Jersey. The garden produces about 1500 pounds of produce annually, which is 100% donated to soup kitchens in Newark and New York City. He also manages a backyard compost system for use in his own garden.

FREE ON-DEMAND WEBINAR & Q/A – RECORDED JAN.21, 2021

Landfills, compost facilities, transfer stations, and renewable energy plants are cognizant of odor issues and strive to minimize odors. Proactive odor management is critical to the continued success and operation of these facilities.

More so than ever before, the solid waste industry faces complex and challenging odor issues based upon public, regulatory, and legal actions. Since odors are generally enforced through nuisance regulations, compliance can be difficult to achieve, not to mention almost impossible to define. Enforcement of odor nuisances is subjective, usually at the discretion of an environmental inspector or Air Pollution Control Officer, and often based upon citizen complaints. When citizen complaints mount, and enforcement action is leveraged, lawsuits often surface as an added ongoing challenge to waste facility operations. Now politicians are demanding action and using alleged odor violations as part of their environmental platforms. Facing odor issues can be costly and threaten the intended land-use designs that waste facilities require to serve their local communities.

SCS Engineers’ January webinar was for those who want to learn more about the proactive strategies and practices you can implement at your critical solid waste facilities. This free webinar will help you develop capabilities to assess the potential for odor issues and, by doing so, set realistic benchmarks toward cost-effective and meaningful mitigation measures.

Our panelists bring comprehensive expertise to the table, including facility design and planning, technical experience in air quality compliance and pollutant dispersion and air measurement programs, atmospheric dispersion and transport of airborne pollutants, particularly in the area of complex terrain. They will provide decades of strategies, resources, and best practices and technologies based on successful solutions that help support your facility as you prepare for, and likely will, experience odor complaints.

The team answers questions throughout the presentation, and the second portion of the program is devoted to Q&A and idea exchange.

Register for SCS Engineers’ January webinar to learn more about the proactive strategies and practices you can implement at your critical solid waste facilities. This free webinar will help you develop capabilities to assess the potential for odor issues and, by doing so, set realistic benchmarks toward cost-effective and meaningful mitigation measures.

DATE: Thursday, January 21, 2021 TIME: 2 p.m. ET

Our panelists bring comprehensive expertise to the table, including facility design and planning, technical experience in air quality compliance and pollutant dispersion and air measurement programs, atmospheric dispersion and transport of airborne pollutants, particularly in the area of complex terrain. They will provide decades of strategies, resources, and best practices and technologies based on successful solutions that help support your facility as you prepare for, and likely will, experience odor complaints.

The team answers questions throughout the presentation, and the second portion of the program is devoted to Q&A and idea exchange.

Pat Sullivan discusses two case studies that provide examples of two different approaches to odor management. The proactive approach resulted in a more positive outcome than the reactive approach. Although the odor issues never go away completely, the proactive facility has avoided lawsuits and regulatory enforcement and continues to have a positive working relationship with the community.

SCS Engineers freely shares our articles and white papers without imposing on your privacy.

Click to read Part I of this two part series. We’ll let you know when Part II is published soon.

Most of us are familiar with small-scale backyard composting and with large-scale yard waste composting on bigger sites, typically outside of urban areas, using open windrows. But did you know there’s a lot of room between those scenarios to compost small to medium amounts of organics on limited land and/or in a more urban environment?

The NYC Compost Project Hosted by Big Reuse is one example. This urban food scrap compost facility, funded by the New York City Department of Sanitation, is tucked under the Queensboro Bridge. It uses a covered aerated static pile (ASP) system with the GORE® Cover System technology. The cover controls odors and vectors, and the aeration system and semipermeable membrane cover provide the needed air flow to support composting. The current system processes 400-500 tons of food waste annually, with plans to double that capacity on a new 1/3-acre site, designed by SCS (construction is scheduled for Summer 2017).

For a slightly larger site with a few acres available for compost facility layout, a hybrid approach may be the best bet to balance the needs for odor control, compost quality, and cost control. A hybrid approach may include an aerated static pile system as Phase 1 of the composting process, followed by open windrow processing as Phase 2. The aerated static pile provides a superior process and odor control during the critical initial weeks, while the windrows provide more cost-effective management through the completion of the composting process. A hybrid design proposed by SCS for a city in the Northeast can process about 4,000 tons of food waste plus 6,000 cubic yards of yard debris annually on a 2-acre site, with an estimated processing time of 4 to 5 months per batch.

In Wisconsin, compost facilities are regulated under NR 502; however, facilities processing less than 20,000 cubic yards of yard waste or less than 5,000 cubic yards of source-separated organics are exempt from many of the code requirements. Check out our compost reference Composting Exemption Reference List for details.

Suggested Contacts

Contact the author, Sherren Clark, PE, PG, for programs in the Upper-Midwest, or Greg McCarron, PE, about programs in the Northeast.

Contact to speak with a professional in your state about getting started.

Suggested Resources

U.S. Composting Council website

SCS Engineers Organics Management and Composting site

State agencies such as the Department of Natural Resources, Pollution Control, or Environmental Protection are usually excellent sources of information.