The EBJ Technology Merit Award goes to Melissa Russo and the team leading the SCS RMC Drones with GIS program. This RMC program provides landfills and solid waste operations across North America with the technologies to optimize operations and address major challenges. As presented at the U.S. EPA’s recent Landfill Technology Workshop, SCS RMC combines sensors with SCS drone-based technologies and GIS to monitor landfill gas (LFG) emissions and detect leaks, eliminating a significant portion of the manual effort from quarterly compliance while performing operations more safely and accurately. Captured emissions data is useful for optimizing well fields, tackling odor issues, and quantifying emissions for renewable natural gas projects. The secure application enables supervisory control and data acquisition (SCADA), data management, and can automate regulatory reporting needs. Aerial surface emissions monitoring collects real-time, accurate data, which is critical for operations to keep a wellfield balanced. Data collected can also visualize below-surface conditions for individual wells or well clusters in trouble areas; zoom in to inspect an individual well’s liquid levels, pump locations, surface, subsurface, and perforated piping; and detect which wells need servicing and their impact on emissions. Thermal imagery and a 360-degree camera inspect the structural integrity of landfill flare systems, and a combination of aerial and terrestrial LiDAR imagery creates Building Information Modeling, detailing the physical and functional characteristics of buildings and other assets.

The EBJ Project merit Award goes to SCS Engineers & Grow America for the Casa Ramona remediation work. Grow America and Casa Ramona won a $4.9-million Site-Specific Cleanup Grant. SCS Engineers led the grant application and is the environmental consultant implementing funded restoration efforts. Casa Ramona has served the San Bernardino, California, community for several decades as a community-based non-profit organization. Debris from fire and demolition had left lead and asbestos-containing materials on its proposed site for community services, including childcare and senior housing. With funding under the ECRG grant, SCS performed the priority cleanup activities: removal, packaging, and disposal of lead and asbestos materials and removal of possible asbestos-impacted soil following the South Coast Air Quality Management District Procedure 5. The community can reuse the site for crucial low-income senior housing and a community center. Congratulations to Cristobal Ramirez and his team.

The awards will be presented at the 2025 Environmental Industry Summit in April.

Orange County Waste & Recycling (OCWR) hosted a landfill tour showcasing technologies used at the Frank R. Bowerman Landfill as part of the August California Resource Recovery Association (CRRA) Conference & Trade Show. SCS’s Remote Monitoring & Control (SCS RMC) demonstrated advanced technology that protects neighboring communities, workers, and the environment from methane naturally produced as waste decomposes.

Landfills use complex systems to achieve the appropriate balance and tuning of the gas collection and control system (GCCS) at a sufficient extraction rate. The rate optimizes the effectiveness and efficiency of the GCCS to minimize fugitive LFG emissions while simultaneously preventing air intrusion caused by overdrawing wells. The collection and control process minimizes the migration of subsurface gas and odors while operating in accordance with federal, state, and local air quality regulations and air quality permit requirements.

Each landfill is unique, but these new technologies can also help protect a landfill’s bottom liner and final cover systems by controlling the accumulation of pressure due to the presence of LFG within the waste mass. Landfills collecting LFG as fuel for a landfill gas-to-energy facility or renewable natural gas plant can better maintain high gas quality. Where applicable, the technologies can help remove heat to contain and manage subsurface reactions in elevated-temperature landfills.

At the OCWR Landfill Tour, there was much to monitor and measure, including operational parameters such as pressure, temperature, gas composition, flow rate, and liquid levels at individual wells. Collecting this information at each well is time-consuming, expensive, and sometimes difficult to collect on foot. SCS RMC demonstrated the evolution of technologies enabling continuous and remote collection and measuring multiple parameters in real-time with automated wells.

Evelyn Martinez scanned the demonstration area for LFG using a drone, demonstrating how drones quickly collect methane data to detect anomalies. A monitor displayed real-time drone data collection, and a second monitor showed real-time flare station data and past methane drone scans of the landfill.

Omar Rodriguez and Marco Quen demonstrated handheld methane detection instruments using optical, thermal, and other sensors and how automated wellheads utilize in-line sensor technology and do not require pulling a gas sample into an analyzer sensor. There was also an odor monitoring and reporting station, and the technology guru Phil Carrillo brought his robodog.

About OCWR

OCWR manages one of the nation’s premier solid waste disposal systems, serving residents and businesses in the County’s 34 cities and unincorporated areas. The three active landfills, including the Frank R Bowerman Landfill, reflect environmental engineering at its best and are among the largest in the state – annually receiving more than 4 million tons of solid waste.

These state-of-the-art facilities take pride in being good neighbors. The landfills use sanitary and environmentally friendly operational methods and advanced technologies that have earned them multiple awards for their modern management techniques, regulatory compliance, and environmental practices, including noise reduction and visual screening techniques, natural habitat planting and re-seeding, the use of falcons and hawks to reduce the number of scavenger birds, and weed abatement provided by real goats.

OCWR currently operates greeneries in Irvine, San Juan Capistrano, and Brea. The full-circle recycling program starts with curbside residential collection of green and organic waste transformed into high-quality compost and mulch and returned to the community as a free resource to enrich gardens and landscaping. Composting helps reduce greenhouse gasses and preserves future landfill capacity.

OCWR’s Renewable Energy Program manages the beneficial reuse of landfill gas through power-generation partnerships that produce 380,000 megawatt-hours of electricity annually.

The SCS RMC team sends thanks to OCWR for helping to educate the public, agencies, and the waste management industry on the benefits and uses of modern landfill technology at work!

Landfill Technology Resources:

While performing methane reduction operations and monitoring at the Anchorage Regional Landfill in Alaska, members of the SCS RMC drone team met some pretty amazing people, including Shane Christiansen who works for the Municipality of Anchorage. The RMC team got to know Shane and learned how he and his business partner, Tim Harrington, are helping disabled children.

Shane and Tim run an organization called Children Leaving Tracks (CLT) that has the mission of providing mobile technologies to young people with limited mobility, allowing them to participate more fully in everyday activities with their peers. They believe that providing improved mobility can expand the physical and mental well-being of these kids and offer them greater freedom and quality of life.

Moved by Shane and Tim’s passion and dedication, SCS made a donation, which will provide “Electric All-Terrain Trikes” to three children! “Everyone deserves to have these experiences in life, but unfortunately this kind of technology is not always covered by insurance companies,” says Shane. “This means that some people go their entire life without getting to enjoy all that it has to offer. They don’t have the freedom to [move about] as they please.”

Although still in the early stages, Children Leaving Tracks seeks financial and in-kind donations from sponsors and networking partners. They are working toward creating a corporate/private collaboration that has the single mission of helping disabled children become more mobile for their health and personal growth.

CLT uses funding to run the organization to supply and finance Track Chairs and Electric Trikes. Donations cover the costs of purchasing and shipping these chairs to the kids who need them. Shane and Tim are registering Children Leaving Tracks as a 501c3 non-profit company; they are also starting a parent company aimed to be the primary funding arm that will supply a percentage of revenues from more recreational products it plans to develop.

The ultimate goal is to change the lives of hundreds of children by opening up their world through greater mobility and freedom. The organization helps youngsters gain confidence, better mental and physical health, and create greater opportunities to expand their individual talents. Kudos to Children Leaving Tracks!

Learn more about how this inspirational organization uses new technology to make life better; or to help, please contact Shane Christiansen at 1-907-529-5153.

If you would like to know more about using technology to improve the environment, ask SCS click here.

SCS Engineers is providing landfill gas (LFG) systems operations, monitoring, design, and management for the Yolo County Central Landfill (YCCL). SCS Field Services is SCS’s specialized landfill practice, providing operations, maintenance, and monitoring (Landfill OM&M) for Yolo County and over 600 landfills across the nation.

SCS Field Services identifies practical strategies to optimize the performance of landfill gas (LFG) systems and equipment while working on site. Optimized systems capture more gas.

Project Manager Mike Calmes leads the comprehensive team at YCCL, which has five closed waste management units, five active waste management units, and one under construction. Closed landfills continue generating gas, so active or closed, they all require oversight by these landfill specialists.

“The County understands the importance of preventative strategies using captured landfill data to create sustainable environmental controls. These keep landfills running as efficiently as possible and safely within regulatory compliance,” said Anton Z. Svorinich Jr., SCS Engineers Vice President, Regional OM&M Manager.

To learn more about landfill operations and engineering, visit SCS Engineers.

SCSeTools® – Developed by Landfill Gas Practitioners for Landfill Owners and Operators

The Birth of LFG Data Tracking

In the early 2000s tracking landfill gas data at facilities was anything but uniform, organized, or secure. The industry was using various methods to track data on paper forms and logbooks, then transferring it by hand into spreadsheets. Some of us used desktop database applications, but as the saying goes, necessity is the mother of invention.

From an SCS employee’s idea for demonstrating how to use landfill gas monitoring data to analyze and pinpoint system corrections, SCS DataServices® was born. In the span of several months, a team of SCS’s landfill engineers, field technicians, and technology gurus worked with client-needs to create a concept application visualizing collected landfill data on maps. Our staff field-tested it with good results, and SCS Field Services began using the application to visualize issues with wellfields that aren’t readily apparent when looking at spreadsheets.

A large SCS landfill client had seen our field staff using DataServices, asked if SCS would consider providing them with access to the application on a subscription basis. Our team adapted DataServices, added features, and continued improvements tailored for the client’s use.

As soon as secure data transfer became feasible, SCS moved to an Internet-based solution for our landfill gas practitioners. The platform called SCSeTools® holds the data collected by SCS DataServices®.

Applications and features roll out as we continually update and upgrade, incorporating ideas and improvements from our users and staff along the way. DataServices is addressing the landfill gas management needs of over 600 landfills across the US and Canada in 2021.

The keys to success follow our mission and values of maintaining close communications with our clients, field staff, engineers, and eTools support staff (all landfill gas practitioners), with the help of software engineers. Technology companies are not up at night thinking about landfill operations, but we are.

We introduce our SCS eTools landfill technology capabilities and a few of the creative and talented SCSers behind the technology in the next segment. Our speakers walk you through demonstrations of how over one-third of the landfill owners and operators in North America are increasing efficiencies using SCS eTools.

Visualizing Landfill Challenges – Shortcuts to Keeping Your Wellfield in Balance

DataServices shows the entire wellfield for any monitored parameters and zooms in on troublesome areas or wells. Results can be as simple or detailed as the landfill owners’ environmental and business needs dictate. The detailed examples here illustrate how graphs, maps, and charts help keep the wellfield in balance. We link each challenge to the description of a video demonstration.

In balance means extracting more gas for renewable energy, preventing odors and methane migration, keeps subsurface and surface conditions and workers safe. The information can help diagnose equipment conditions before they become costly, maintain regulatory compliance, and support cost estimates if the landfill is expanding or more infrastructure investment or equipment is needed.

Looking at vacuum distribution across a gas collection system – Select the system pressure map, which highlights vacuum distribution across the wellfield to show the wells with good (expected) vacuum, pressure drop over distance, and any wells unexpectantly losing vacuum. Zooming in and changing the vacuum ranges further enhances where to assign staff to troubleshoot any identified issues.

Using a methane distribution map shows whether the wells are tuned to where the landfill owner wants them. Wells may be identified below the targeted range, indicating slight over pulling; a technician can use this map to identify such issues and quickly check the identified wells. Wells identified above the desired methane tuning range indicate wells not collecting enough gas, which has consequences. These wells can be the source of odors, leachate seeps, possible lateral migration to an out of waste probe. Not sending enough fuel to a power plant or atmospheric releases can affect surface emissions monitoring.

Managing liquids – Changing waste streams and more rainfall in certain areas of the country complicates liquids management. DataServices visualizes the impacts of liquids on wells and helps landfill owners better manage a proper liquids removal program. The program will let them know how many pumps to budget for and, over time, where to relocate well dewatering pumps so that they are most efficient at removing liquids from landfills.

High-BTU Gas Plants –Filter maps help users locate wells contributing to gas dilution into renewable energy plants. It can help create punch lists for landfill staff to investigate, troubleshoot and tune. As wellfield technicians make corrections, they show on the map in real-time.

Temperature and subsurface oxidation events – Some call the condition subsurface fires, but this is a serious issue for landfills. Over-pulling wells, damaged infrastructure, and other conditions can cause oxidation events. Using a combination of temperature Parameter Maps to review wellhead temperature distribution and a Points Chart feature provides a deeper dive into the data. It provides more insight into which well or wells may be contributing to the high-temperature issues.

Locating a specific well – That’s not so easy when hundreds of wells surround you and at larger landfills. DataServices had built-in filter features to identify a single monitoring point on a wellfield map easily.

Customizing for compliance, best practices, and rules – DataServices allows monitoring points across a single site to have customized rules for each monitoring point. Rules can be for regulatory purposes, standard operating procedures, best management practices, and even site-specific preferences or any combination thereof. It is efficient to customize rule application to landfills and collection points – meaning wells, probes or ports, horizontal collectors. This customization capability helps organize and confirm regulatory compliance. It is especially salient with the 2021 EPA and state compliance changes for a single landfill or an organization with hundreds of landfills.

MobileForms – Inspection forms, blower flare station monitoring forms, load tracking from municipalities, incoming hazardous waste tracking, MRF bale counts are examples of paperless entry available. The data feeds directly from mobile phones to the supervisor and into the maintenance department, so staff can start cataloging and looking at what’s going on in real-time at several types of facilities. It’s available for regulators and inspections and helps reduce staff hours tabulating and centralizing the information. Any information historically captured on a form or log attached to a clipboard can now be captured and stored electronically. From there, it can be recovered and produced as a PDF export file or data from the forms used to trend data and help make informed operational decisions.

MobileTools – DataServices in a condensed format suitable for mobile devices. Field staff use MobileTools to save time formerly used to return to the office, transfer/transcribe the collected data and upload it to a supervisor for quality checks before storage. Technicians can now recall the last 20 readings for any given well and review trend graphs on their phones or tablets while standing adjacent to the well they have questions about and need to access the data. MobileTools also allows them to upload field data such as liquid level readings while the data is being collected. The information instantly populates into DataServices and is available for review by others on the project team.

The most valuable tools are in development now for release in 2022. ARC GIS integration developed under SCS RMC® will further enhance DataServices with even better visualization and location capabilities and provide enhanced features such as allowing landfill owners to see their well as-built information and view subsurface information about their wells.

Learn more at SCS Engineers, where we adopt our clients’ environmental challenges as our own.

Landfill data collection and analysis are more tactical than ever, and landfill technology provides methods to manage and use the data to create efficiencies. With the implementation of the NESHAP, NSPS/EG requirements, Landfill Operators will monitor more often and maintain more records. Data collection mechanisms will likely broaden soon to include drone and satellite data collection as acceptable for agency requirements.

Our September 23, 2021, SCS’s Client Webinar focuses on landfill gas maintenance and how Operators find efficiencies by monitoring and collecting LFG data. Using SCS eTools, the webinar includes common scenarios at landfills and answers several questions, including:

Demonstrations include:

The International Awards Committee and Solid Waste Association of North America (SWANA) Board of Directors unanimously voted to honor Tom Conrad, the “C” in SCS, with the Robert L. Lawrence Distinguished Service Award at WASTECON 2021 in November. The Lawrence award is the highest accolade SWANA bestows on a member of the waste management industry, reserved for those making meaningful and lasting contributions.

“I’m honored and humbled to be selected for the Robert L. Lawrence Award. I thank you and am especially thankful for what SWANA and SCS are today,” stated Tom Conrad.

SWANA recognizes Conrad for over 60 years of significant influence on the waste management and environmental services industry. Conrad, a Founder, Executive Vice President, and Director Emeritus of SCS Engineers, dedicated his career to advancing solid waste management, most notably through the founding of SCS Engineers (Stearns, Conrad, and Schmidt Consulting Engineers) more than 51 years ago.

Tom Conrad worked on a wide range of environmental engineering projects touching almost every aspect of solid waste management throughout his career. As an environmental engineering firm and consultant to the newly created US Environment Protection Agency (EPA), the founders recognized that responsible solid waste management was increasingly important for protecting the environment and the health and safety of the general public.

Leading SCS, he helped the EPA develop the first federal regulations for sanitary landfills, managing and capturing landfill gas, waste sorting protocols, sludge management, and land remediation.

Environmental services, including wastewater management, were always a significant part of SCS services and the waste industry. When new regulatory policies began expanding in the ’80s, SCS’s techniques, technology, and expertise helped a broad range of industries comply with environmental needs and continues today with the firm’s greenhouse gas, landfill technology, renewable energy, remediation, and sustainable materials management programs.

Conrad is also known for hiring and mentoring today’s SCS leaders, many of whom are SWANA leaders, by creating and fostering SCS’s culture encouraging employee participation in industry associations, community, and SCS’s mentorship and leadership programs.

Before his retirement in 2016, Conrad held professional engineering licenses in 24 states. He was a member of SWANA, the American Society of Civil Engineers, the National Waste and Recycling Association, and the Society of American Military Engineers.

He maintains his “work hard – play hard” lifestyle. He is active at SCS, participating in Board of Director meetings and speaking at the Young Professionals Group events and celebrations. While no longer mountain climbing and biking cross-country, he has a vigorous walking, swimming, and biking schedule.

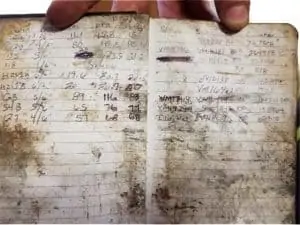

In her first job at SCS Engineers, Joy Stephens worked in a small trailer, consolidating and analyzing data from landfill field techs’ notes, recorded in logbooks they lugged around while navigating the challenging site terrain, then brought to her covered in leachate and mud.

She cross-referenced their detailed, handwritten records with a master list posted on a wall, organized, and methodically examined them. Then she turned them into actionable intel for SCS’s engineers and scientists.

“That was definitely easier said than done. It was a lot of work – a lot of hours to make sure that we were ready for the next day. It struck me that there’s got to be a better way. That we could make collecting and using this valuable information easier for the field staff and OM&M (Operations, Monitoring & Maintenance),” she says.

GIS Supports Wellfield Operations

From that inspiration came a lot of brainstorming, developing, and tweaking what today is a powerful yet user-friendly GIS system that stores and organizes volumes of geographical information in one place and gives users what they need fast to troubleshoot landfill conditions. The customizable application is now used at hundreds of landfills across the country, mainly to support wellfield operations, though it has other landfill system applications.

Field techs enter information onto digital forms using a mobile app and submit the data, uploading it to the cloud. OM&M teams have it in a streamlined format in a couple of minutes and can visualize what they are looking for on maps from a dashboard.

The technology that Stephens was an integral player in launching continues to evolve, and there’s a story behind that evolution.

“In the beginning, I reached out to this brilliant young lady, Brooke Aumann, from the Tampa office, who does a lot of GIS work. I had some GIS experience myself, but more landfill knowledge. I picked her brain so we could set up a digital replacement for the logbooks that zeroed in on exactly what the field techs and project managers needed to support our clients,” says Stephens, an environmental scientist.

Together, the two women created experimental web maps to plot and visualize basic information such as the location of each monitoring point, points requiring the collection of liquid levels, and the status of maintenance tasks at each well. Then they developed digital survey forms with more detailed information and connected those forms to the maps; this enabled end-users to overlay even more data for a holistic snapshot of what goes on at wellfields.

“We tried different configurations of web maps and symbology to depict best what we wanted to convey. We talked about what we needed to symbolize and how we needed to symbolize it. And we discussed possibilities for future developments. We knew much more was possible in terms of what we could collect, how all of these data are connected, and how we could exploit the software to better tackle more complex tasks,” Stephens says.

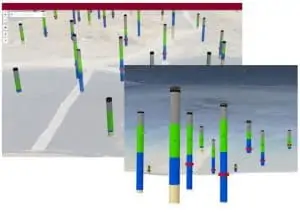

From maps to interfacing data forms to the next level X-ray vision

“Now we’ve gone a step further. We’re doing 3D well visualizations, which give a kind of Superman X-ray vision subsurface. You are literally looking beneath to the well to get good intel,” Stephens says.

Traversing the World

With undergraduate degrees in Mandarin Chinese and geology and graduate degrees in teaching science and environmental management, Stephens has long loved learning, the environment, and nature.

“When I was young, my parents were missionaries, and I grew up in the most beautiful, pristine, remote areas, like the Solomon Islands and Vanuatu – so unspoiled and lovely.”

It was a sharp contrast to what she would see later when she moved with her young son to China, where she taught math and science. The air quality was poor, and the streets and landscape were inundated with litter.

That experience was the final push that landed the young professional at the foot of a career path she’d considered for some time; environmental sciences. She’d taught it before, but a voice inside her was telling her to pivot and actually start doing the work.

Stephens found her way into a program at a university in Scotland after researching graduate environmental management programs worldwide. At this prestigious learning institution, she first worked with remote sensors and GIS, identifying and addressing “waste crimes,” namely illegal dumping.

Seizing the opportunity to apply her expertise

After graduation, the teacher-turned-scientist took her education and experience back to the United States and SCS Engineers. The company was not foreign to her. By the time she applied, she had made as much a project of vetting employers as she had of scoping out universities. Two draws drew her attention:

“There is the ethos; SCS is genuinely committed to the environment. And the other part that was important to me is SCS is very invested in professional growth and training to foster that growth. I believed that I would have opportunities to move up,” Stephens reflects, recalling when she said yes to the first job working with those logbooks that would be the catalyst to what was to come.

When she came on board, she had to gain practical experience in the solid waste industry and learn the ropes in the field, in addition to her prior experience in renewable energy. In time she had learned her way around landfill gas collection wells, then kept building on that knowledge.

“I asked a ton of questions. Why are we monitoring for this? What constitutes good gas quality? Why is it important to know liquid levels? What is the difference between vacuum and flow? I think asking all these questions, collecting field data myself, and watching what the guys in the field had to do, gave me a good base understanding to help inform how we would capture the right information using GIS. It was a collaborative effort. Brooke worked on many landfill projects and my colleague, Chris Carver, had 16 years of field and project management work. It all came together.”

She later joined the RMC team (Remote Monitoring and Controls), where she received further training in GIS and mastered other skill sets. Today she is a project professional specializing in GIS and drone services.

At home with waste management

The hybrid techie-artist in Stephens comes out when she makes an analogy that tells a little of how her wheels turn.

She grew up playing Legos and now, at almost 40 years old, still builds with them at home with her son.

She approaches the job the same way as when she assembles those sets.

“You know the pieces fit to make something, but it takes creativity to figure out just how to build it and make it as visually pleasing and functional as you can, or to get it to function in different ways. I try to configure and piece together for the best possible design,” she says.

Stephens has married that approach with a desire to be a part of both restoring and protecting the environment. She thinks she’s in the right place to act on that intention.

“I feel like work with waste management and SCS is a way to achieve what I think is so important. We are trying to protect, remediate, and leave conditions better than we found them. That is what being a good steward is all about.”

See Joy Stephens at work in her recent educational presentation for landfill owners and operators. Joy demonstrates technologies to reduce the time to collect, process, and show data.

Dave and Dennis discuss how operational improvements are being made in this essential service and its environmental footprint. They dive into the 24/7 maintenance and monitoring of landfills, adjusting to changing conditions in real-time, reducing cost, generating renewable energy, improving the health and safety of operators, and being proactive in a changing world. We also hear about an Ignition-based solution called Connected Landfills that improves connectivity, mobility, and visualization by using data science to facilitate better decisions.

Apple Podcasts | Spotify | Google Play | PodBean | TuneIn

When Melissa Russo’s boss Phil Carrillo told her he thought she should get her drone pilot license, she thought he was kidding. At the time, she worked on SCS’s Remote Control (RMC) team; selling drone services was a part of her job, but she had not thought of flying these unmanned vehicles herself.

Her thirst for competition kicked in when he turned the proposition into a bet. He was going after his pilot license himself; she bet she’d beat his score. They finished in a dead heat, but what started as friendly rivalry ended up bringing a new dimension to Russo’s job— a job that continues to expand in breadth as new opportunities turn up.

Today she not only flies, sells drone services, and teaches others how to sell and fly, but she’s helped bring geographical information systems (GIS) into RMC’s portfolio. How these technologies fit together is RMC remotely collects data from drones and different landfill systems. Then the GIS translates that data into maps, capturing a visual picture of how clients’ facilities’ systems are performing. The GIS piece is one of the latest chapters in the story of Russo’s evolving role (more to come on that).

Piloting is what especially gets her juices going.

“I love working with my team, supporting them in what they do. But when it comes to drones, I like the hands-on experience of flying myself more than telling other people how to do it.”

She controls these small aircraft from a device on the ground, sharply focused on her surroundings while keeping the drone in her sight at all times.

“You have to make sure there are no manned vehicles around; they have the right of way. And there’s a lot of continuous movement on landfills. You’re constantly aware of your surroundings. Is a truck coming? Am I in line with where dumping is going on?”

Flying drones takes muscle and mechanical aptitude.

The drone and case can weigh 45 pounds. And there are a lot of moving parts to assemble and calibrate.

Sometimes it’s manual work, pointing and rotating a remote controller to send a radio signal to tell the drone what to do. But more often, she pilots automated flights that she maps in advance and uploads the flight path specs into software that interfaces with the drone.

“When I’m flying drones, I can access areas where if I had boots on the ground, I couldn’t. I can go and explore just about anywhere, similar to when I dream— only it’s real,” she says.

With any task, she’s laser-focused, concentrating on one part of the picture at a time to grasp the details. She steps back and uses critical thinking, accumulated knowledge, and imagination to take on what’s before her.

The innovation process

“We’re pretty lucky with our timing; new and proven technologies are emerging quickly. I’m one of many SCSers with a deep knowledge of technology and practical experience in the solid waste industry. Together, we can make a difference because we understand the business and operational challenges very well. When I need an expert in another industry, I just reach out to a colleague. The learning process never ends, and each project helps me and my team constantly find better answers.

“My boss is more of a big-picture person; his ideas are huge and amazing. He comes to me with new ideas, and I figure out how to make them work and implement them,” Russo says.

She points to his idea to use proven GIS technology within RMC. She was already using GIS to map methane data, process topographic maps, and stockpile calculations. For instance, she integrates methane values into the GIS and overlaps them with imagery so her clients can zoom in on one well or get a large-scale view of the overall health of the gas collection system. But integrating GIS in new ways to incorporate multiple landfill systems would solve some expensive problems and, better yet, prevent even more expensive mitigation and repairs.

Expanding GIS applications to illustrate multiple landfill systems

“I know drones and how to process drone data. But now that we are expanding applications, I add more layers of landfill data, such as liquids, soil, the gas collection and control system (GCCS), SCADA, and surface emissions, to bring them into the RMC GIS platform. My colleagues are demonstrating these technologies at the SCS June Client Webinar.”

“I created a team of hand-picked SCS staff with both GIS and waste management backgrounds (and a whole lot of drive) to make the vision come to life,” she says. “That’s how we innovate, tight teams with access to nationwide expertise.”

Within six months of the project’s genesis, Russo and her team had integrated gas and liquid collection systems, other landfill systems, and asset management into the RMC GIS platform. She and her team now sell these applications nationwide.

Russo’s come a long way since joining SCS at age 21

In her mind, she grew up at the company. Before coming on board, she managed a shop in Manhattan Beach, California, while she began thinking about what to do next.

“I learned a lot about business and people. It was a stepping-stone – I discovered how to earn trust, build rapport, and sell. But in time, I decided I wanted a more professional job,” she recalls.

She went to work for a real estate company managing the SCS Engineers Long Beach office, where she would soon take an entry-level Accounts Payable position in SCS Field Services.

In time, she transitioned to the Health and Safety group, assisting in creating training material and managing truck fleets. Soon she was managing assets, among other firsts for her. By this point, she had developed enough software, accounting, and other administrative skills to step up fast.

Part of the job was keeping up with vehicle maintenance, so she often spoke with field staff. Many of them she already knew from her days working in the accounting department.

Growing with her SCS colleagues

“When I was in my first administrative roles, I supported many colleagues who were field techs or supervisors; they are project managers now. It feels as though we’ve grown up together, and we know and trust each other. We collaborate well and know that when we bring projects to each other that we will take care of each other,” Russo says.

She especially likes the RMC concept because remote control and automation enable her, her clients, and her team to work smarter, not harder because they leverage the technology to work for them.

“That means we can usually work from anywhere, giving all of us more time for family, friends, or allocating the time saved towards other needed to-dos. I’m up at five a.m. and, at times, may not finish work until nine at night. Somehow, us working women find the balance in between meetings, writing proposals, and answering emails; I have lunch with my two boys or take them to a park,” she says.

Bambi Lance, a veteran SCSer and her mother, works in the same business unit as Melissa does. “Mom’s been here for 16 years, and it’s interesting to have her perspective not only as my mom but as someone who knows SCS. She knows my department, and she knows me. She sees what I am doing and she along with management encourage me to do more and believe in myself.”

Russo reflects again on the concept of stepping-stones on the way to knowledge and maturity. I’m competitive and take on challenges, which has been a driving force in all I do today. It’s helped me take a personal inventory of how I am now versus the young Melissa,” she says.

She uses it to gauge her direction. And she uses it to connect to her staff. “I try to help them see you can turn almost any experience, into a positive. I want my team to see we are all learning and growing. They can, as I can, comfortably bring new ideas to the group and company, which often turn into new ways to help clients.”

She circles back to her decision to fly drones, explaining how it aligns with her career path from her first steps to today. “Becoming a pilot was a natural fit because it’s a new challenge. The craving to take on new tasks is how I grew from an accounting administrator to a project coordinator up to a business manager. It’s wanting to expand my knowledge, tackle new feats, and accomplish what I was not sure I could do. I like the challenge.”

The SCS Culture is Driven by Client Success