Pressure Release System Near Bottom of Landfills – Essential Component for Proper Functioning of the Landfill Drainage Layer

Landfill designers are generally diligent in performing extensive leachate head analysis for the design of the geocomposite drainage layer above the bottom geomembrane barrier layer. They perform HELP model analyses considering numerous scenarios to satisfy all requirements of the regulatory agency reviewing their work.

It’s great that the practice of landfill design is widespread and there are many solid waste professionals in the industry who can perform all sorts of analyses. However, there is a need for special attention to an operator’s observations in the field, sometimes lost in the course of communications. Unless one works in an organization with field services or closely coordinates the design with field operations personnel, some strategic considerations are never incorporated into the best design.

One phenomenon that solid waste designers may not be aware of is that significant landfill gas may accumulate near the bottom lining system and cause pressure build-up in and around the bottom lining system during waste filling operations. Fresh waste placed in a newly constructed disposal cell generates a significant amount of gas due to the presence of high levels of oxygen in the fresh waste lift. High levels of oxygen cause aerobic decomposition of waste with significant gas generating capacity.

High gas pressure builds near the leachate collection system means high gas pressure in the voids of the sand/soil layer above the geocomposite drainage layer, and the geocomposite pores. High gas pressure within the geocomposite can adversely affect the free flow of leachate through the geocomposite to the leachate collection pipe. This phenomenon can potentially cause a significant increase of leachate head within the geocomposite drainage layer, and even potentially cause saturation of the overlying sand/soil layer in some cases.

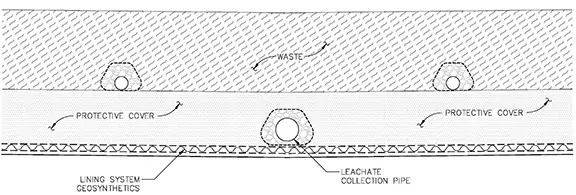

Address this situation by including a pressure release system in the design of the lining system. The pressure release system is a simple system including perforated HDPE pipes placed in parallel position at a certain spacing above the sand/soil layer in the longitudinal direction of the disposal cell extending from the perimeter berm, at the low end of the disposal cell, to the high end of the cell. The pressure release pipes extend to the top of the perimeter berm at the low end of the disposal cell and terminated by blind flanges. When pressure builds in the cell near the lining system, these pipes, connected to a vacuum source in the vicinity, remove the excess gas pressure from the bottom of the landfill.

The spacing of the pipes in the pressure release system and the design of the pipe bedding material are up to the designer. Such a system can be beneficial in removing gas pressure near the lining system throughout the life of the landfill, allowing the geocomposite drainage layer to function as intended in the design of the facility.

I have observed numerous cases of leachate not percolating through the geocomposite, that for any number of reasons was exposed during construction activities, simply due to excess gas pressure near the landfill lining system. I have also observed distorting of blind flanges at the end of the cleanout pipes due to high-pressure build-up near the lining system. Including a pressure release system for a nominal cost in your design can prevent the drainage layer, a major investment in the construction of the landfill, to function properly and maintain the leachate head within the range of the design parameters.

Based on my experience, I believe that solid waste designers dealing with warm landfills that fall into the category of potential future elevated temperature landfills, where removal of leachate in a very effective manner from the landfill is essential, should seriously consider a pressure release system above the bottom lining system for proper functioning of the drainage layer.

Liquids Management and Landfill Design

By Ali Khatami

MSW sanitary landfills constantly face the issue of aesthetics due to leachate seeping out of the landfill slopes. Of course, the problem goes away after the construction of the final cover, but the final cover construction may not take place for many years after seeps show up on slopes. To the public, leachate seeps represent a problem with the design of the landfill and possible malfunction of the leachate collection system below the waste, which is an incorrect perception. Such arguments are common and difficult to counter.

Landfill operators use different means to control leachate seeps from landfill slopes and to clean up the unpleasant view of the seep as soon as they can. Innovative solutions to address the issue have been observed and noted in the industry. The degree of effectiveness of the solution to some extent depends on the amount of money spent to address the problem. Some landfills are located in rural areas and the operator may not mind the unpleasant appearance of the slopes, so naturally no urgency in addressing the issue or no money available to take care of the problem.

The environmental side of the leachate seep issue is the impact to surface water quality. If leachate seeps remain unresolved, liquids coming out of slope may eventually reach the landfill perimeter and mix with stormwater in the landfill perimeter ditch. At that point, the operational issue turns into a compliance issue, and regulatory agencies get involved. If the public around the site is on top of their game concerning their opposition to the landfill, they can take the non-compliance issue and turn it into a political issue. At that point, the landfill operator finds himself or herself on the hot plate dealing with the agency and the public on an environmental impact matter.

It always makes sense to stay ahead of the issues and address any potentially sensitive condition before it turns into a major problem. As discussed above, addressing leachate seeps can be done in many different ways, and the operator needs to be prepared to fight for funds to address leachate seeps as they appear on slopes. Availability of funds and willingness of the operator to take necessary action are the primary required elements to stay ahead of the game.

SCS has developed methodologies to address all sorts of leachate seeps on landfill slopes and is uniquely equipped to assist you with a solution. Reach out to a local SCS office for a consultation if you have leachate seep problem at your site.

See you in Nashville! SCS Engineers

Article and Slideshow of Landfills using these Best Practices to prevent leachate. Click Hot off the Press to view.