The past few decades of advancements in developing new drainage media have led to the use of geocomposites as the primary drainage layer above the bottom lining system geomembrane. However, you need to be watchful for the free flow of leachate through the thin layer of geocomposite under high gas pressures near the bottom lining system.

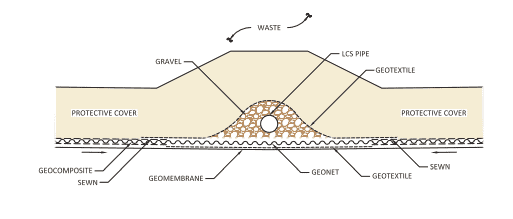

Short of investigations and clear guidelines for addressing high gas pressure near the bottom lining system, you can use a gas pressure relief system near the bottom in future new disposal cells. The pressure relief system can simply include a few perforated high-density polyethylene pipes laid in parallel directly above the soil layer placed above the bottom lining system drainage layer, as shown in the schematic.

About the author: Dr. Ali Khatami

Landfill Leachate Management Services

One general problem that is encountered in traditional designs is the potential for clogging of geotextiles in the vicinity of the leachate collection pipes.

Traditionally, leachate collection pipes are encased in gravel, wrapped in geotextile, and positioned above the leachate collection system geocomposite drainage layer inside a trench or at the trough of the bottom of a cell. In a traditional design, leachate travels through the geonet component of the geocomposite and reaches the leachate trench where the leachate collection pipe is located. Here, leachate must flow out of the geocomposite, through the upper geotextile component, and then through the geotextile wrapped around the gravel, before entering the gravel and eventually flowing through the pipe. The flow through the geotextiles is concentrated in small areas on the two sides of the leachate collection pipe-gravel-geotextile wrap. Considering the large volume of leachate that follows this path over the life of the cell, it is evident why traditional designs are doomed to clog.

The clogging impedes the free flow of leachate from the geocomposite drainage layer to the leachate collection pipe. As the clogging occurs, the leachate must find a new flow path (most likely further back from the collection pipe), and flow out of the geocomposite, through the geotextile wrap at a different location, and eventually enter the gravel and pipe. This new location will eventually clog as well for the same reasons that the initial location was clogged. This process continues until the geotextile within the leachate trench becomes completely clogged and the system loses functionality. Unfortunately, the periodic cleaning of leachate collection pipes (usually every few years) cannot address this issue because the problem is outside the pipe and the high-pressure jets inside the pipes do not reach the clogged locations.

The solution is to eliminate geotextiles from the flow path of the leachate, extending from the geocomposite drainage layer to the leachate collection pipe. Over the past several years, SCS has successfully designed and constructed numerous landfill cells with no geotextile in the flow path of leachate from the geocomposite drainage layer to the leachate collection pipe. The design follows the “Rule of Transmissivities” which dictates that a proper design should provide the free flow of leachate from one medium to another and that only occurs when the transmissivity of the latter medium is equal to or greater than the transmissivity of the former medium. If a design does not satisfy the Rule of Transmissivities, there may be potential for clogging, bottlenecking of flow, and other consequences resulting from impeded flow in the system.

SCS Engineers is a leader in the design of landfill lining systems, and we have experience with issues that may not be familiar to other firms. If you are interested in the design of a leachate collection system at your facility, please contact SCS. Our professional engineers will gladly review your design and make recommendations if needed. We can identify potential issues and improve designs to prevent future problems and maintenance during the life of your facility.

Questions? Contact Ali Khatami, PhD, PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering. Dr. Khatami has acquired extensive experience and knowledge in the areas of geology, hydrogeology, hydrology, hydraulics, construction methods, material science, construction quality assurance (CQA), and stability of earth systems. Dr. Khatami has applied this experience in the siting of numerous landfills and the remediation of hazardous waste contaminated sites.

Read more here. Rule of Transmissivities at Material Interfaces in Landfill Leachate Collection Systems, in Talking Trash

John F. Hartwell, Ph.D., PE., CHMM, and Senior Consultant at SCS Engineers recently successfully defended his dissertation and earned his Ph.D. An abstract of Dr. Hartwell’s dissertation follows:

METHODOLOGY FOR ASSESSING MUNICIPAL SOLID WASTE USING A LARGE-DIAMETER BOREHOLE

LTC John F. Hartwell, Ph.D., P.E.

University of Nebraska, 2015

Municipal solid waste (MSW) landfills are permanent repositories of society’s non-hazardous wastes. Landfill facilities are becoming harder to site, resulting in increasing pressure to maximize the use of available airspace. Increasingly, this results in developing additional airspace by way of vertical expansion. This expansion imparts greater stress on the landfill mass and the containment infrastructure.

The engineer’s understanding of the geotechnical properties of MSW has been limited to sampling of relatively shallow test pits and reconstitution of disturbed MSW samples in the laboratory. Deeper assessment using small diameter borings is difficult and produces poor low volume samples for ex-situ testing. Some researchers have synthesized MSW with obvious limitations. Landfill failures have provided opportunities for back calculation of MSW properties including shear strength, but these estimates are based on limited understanding of unit weight and moisture content with depth.

The recent trend for the harvesting of methane produced by the anaerobic degradation of MSW has resulted in the need for nearly full-depth, large-diameter, landfill gas collection wells. Prior to completion, these boreholes provide excellent opportunities for directly observing and measuring the condition of MSW in its buried, variably degraded state at depths that are far greater than previously accessible.

The large diameter MSW gas well borehole assessment methodology presented in this paper is shown to be an efficient and valuable means for characterizing MSW. This means that the cost of the assessment is relatively low as the drilling costs are negligible and therefore limited to the cost of labor to sample and perform field observation and laboratory testing. The assessment methodology, which includes scaled full coverage photography and videography, allows precise analysis of a number of geotechnical properties such as wet and dry unit weight, moisture content, specific gravity, void ratio, % saturation of MSW and buried soil layers throughout the depth of the borehole. Further, MSW constituents and biologic degradation can be measured. The orientation / alignment of tensile reinforcement within the waste mass is readily observable. Zones of perched leachate and the effects of mechanical creep on borehole diameter can also be measured.

Contact John Hartwell or Contact SCS Engineers

Learn more about MSW Landfill Services from SCS.