Christian Collins, the Deputy Director of Utilities for Manatee County, and Shane Fischer, P.E., of SCS Engineers, take readers through a pressing problem in many communities and regions – dwindling landfill airspace. As populations continue to grow and citizen consumption increases, the amount of waste surges, pushing landfills to their limits sooner than anticipated.

The co-authors guide us through the options a Florida landfill considers and the successful solution they ultimately implemented, doubling the life of the existing landfill’s footprint. This inspiring case study, originally published in Talking Trash, is now shared with our landfill clients, demonstrating that effective landfill management is achievable.

About the Authors:

Christian Collins is the Deputy Director of Utilities for Manatee County, with more than 30 years of expertise in wastewater and water plant operations, design and construction, reclaimed and biosolids management, solid waste facility operation and maintenance, and leading large teams, licensed in water and wastewater operations.

Shane Fischer, P.E., is a Vice President of SCS Engineers. He has more than 25 years of diverse experience designing and permitting civil engineering and solid waste management projects from the initial concept, construction, and operations.

Additional Landfill Airspace Resources:

Join SCS Engineers professionals at the SWANA Florida chapter’s Summer Conference and Hinkley Center Research Forum, July 23-25 in Daytona Beach, FL.

Don’t miss this opportunity to network with some of the best minds in the solid waste industry at this important solid waste conference and tradeshow in the southeast, while earning continuing education hours and enjoying beautiful and exciting Daytona Beach.

The program committee is developing an interesting and educational agenda about the latest developments in the solid waste industry. The conference will explore important topics, such as solid waste management, rate analyses, recycling, zero waste, landfill design & operations, waste-to-energy conversion technologies, disaster debris management, and more!

Several SCS Engineers professionals are presenting at the conference, including

Click for more conference details and registration information.

We hope to see you there!

Hear from SCS Engineers experts at the ninth Global Waste Management Symposium in Indian Wells, California, February 25-28, 2024. SCS is also is a Silver Sponsor of the conference.

The GWMS serves as a forum to discuss applied and fundamental research, case studies and policy analysis on solid waste and materials management. The community of researchers, engineers, designers, academicians, students, facility owners and operators, regulators and policymakers will participate.

Numerous SCS Engineers experts will be on hand to discuss your solid waste management challenges, and several are presenting at the symposium, including:

The Environmental Research & Education Foundation (EREF) is a strategic partner of the symposium.

Click here for schedule, registration, and other conference details

Hope to see you there!

The trend to go larger necessitates more landfill design sophistication and master planning to recoup the growing capital investment upfront. During this month’s SCS Engineers webinar and open forum, our panel will discuss landfill design, focusing on optimizing your site layout and maximizing air space – a landfill’s golden egg.

Live on Thursday, September 29, 2022

2:00 pm Eastern Time for 1 hour

This educational, non-commercial webinar with a Q&A forum throughout is free and open to all who want to learn more about landfill design. We recommend this month’s discussion for landfill owners/operators, solid waste planners, environmental engineers, municipalities, and environmental agency staff.

Certificates of Attendance are available for attendees who registered on Zoom and attended the live session.

Today’s modern landfills offset inflation and labor costs through transformative reduction, recycling, and reuse programs while turning methane into renewable energy. Advanced remote monitoring and control technology and data capture provide many efficiencies and insight to landfill operators and owners running larger and larger collections of plants and facilities on their landfills.

The trend to go larger necessitates more landfill design sophistication and master planning to recoup the growing capital investment upfront. During this month’s SCS Engineers webinar and open forum, our panel will discuss landfill design, focusing on optimizing your site layout and maximizing air space – a landfill’s golden egg.

Live on Thursday, September 29, 2022

2:00 pm Eastern Time for 1 hour

This educational, non-commercial webinar with a Q&A forum throughout is free and open to all who want to learn more about landfill design. We recommend this month’s discussion for landfill owners/operators, solid waste planners, environmental engineers, municipalities, and environmental agency staff.

Certificates of Attendance are available for attendees who registered on Zoom and attended the live session.

The Reno County Board of Commissioners approved contracting with SCS Engineers to support the County’s Solid Waste Department through 2024. SCS will provide environmental engineering, consulting, and field services for the Reno County Municipal Solid Waste Facilities for the next three years. The contract approval directly resulted from the firm’s experience, expertise, and long-standing relationship with Reno County.

SCS has a history of providing compliance, planning, and engineering services to Reno County. The firm helps the County continually comply with the Kansas Department of Health and Environment (KDHE) and other agency regulations. Compliance activities throughout the year include groundwater and leachate sampling, laboratory analyses, permit renewals, air permitting, and associated report preparation in accordance with Kansas Administrative Regulations.

Landfills contain complex systems to protect the health of nearby communities and the environment. The County uses SCS professionals’ expertise and proprietary software for air quality and gas collection and control systems (GCCS) operations, monitoring, and maintenance (OMM). Reno County relies on SCS to maintain these systems and keep them in compliance to focus on their other operations.

These preventative services keep the landfills fully compliant with state and federal regulatory requirements while aligned with the County’s system performance goals and anticipated operational and maintenance activities.

In 2021 the U.S. Environmental Protection Agency (EPA) changed legislation regulating landfills, specifically the New Source Performance Standards (NSPS) and other air quality regulations. These changes significantly increased the monitoring, record-keeping, data management, and reporting tasks for many landfills across the nation, including the Reno County Facility. SCS has helped Reno County navigate these changes and will continue to facilitate changes as the County looks to expand its landfill in the future. Combined with the supply chain and labor shortages, the Solid Waste Department is securing its essential services from disruptions.

Project Director Steve Linehan said, “SCS is privileged that Reno County entrusts us to partner with them to maintain the landfills’ safe and efficient operations. The Solid Waste Department supports the citizens and the environment; we’re honored to help.”

Here at SCS, we work for developers, industry, and manufacturers to help them run cleaner, safer, and more efficiently. This PBS video provides insight into how SCS brings value to the waste industry, our clients, and, most importantly, our communities.

You may ask yourself, don’t pig farms create pollution? Yes, but even that waste is reusable!

Did you know the food you buy in the grocery is supported by our environmental experts? Learn more about SCS’s environmental engineers and consultants who bring contaminated properties back to life, lower and capture greenhouse gases for fuels and renewable energy, and make possible a brighter future.

If you are interested in becoming an SCS Engineers employee-owner, watch our comprehensive video to see the breadth of services our teams offer.

Not too long ago, SCSer Gomathy Radhakrishna Iyer thought she’d become a mechanical engineer but decided to go down another path at her father’s coaxing, and she’s never looked back. Today she is a Civil & Environmental Engineering Ph.D. and has become deeply entrenched in the world of landfills—human-made formations that she calls “beautiful.”

Dr. Iyer’s work spans research and engineering projects in landfill gas emissions reduction, landfill design, and leachate management. She’s also keeping up with PFAS to be ready for what may lie ahead around these emerging contaminants. “What I’m most into these days is researching and helping clients select leachate treatment systems and doing landfill expansion designs. It’s so mentally rewarding when you find solutions for the client’s problems. They are happy, and you are happy,” says the SCS staff professional.

She is known by more than her work family. Gomathy is a published researcher and speaker, most recently presenting at the Global Waste Management Symposium in February 2020. Her presentation covered one of her pet topics, her Ph.D. focus: using grass clippings and biosolids as biocovers to remove methane from landfills.

Pre-COVID, she spent many of her days in the field. Lately, she spends a little more time anchored to her computer in her home office. There she typically works on a few spreadsheets at a time, maybe as part of a gas emissions report, a stability analysis, or settlement analysis. Then she shifts her focus to her design drawings. Dr. Iyer still manages to break away to put on her PPE – her hardhat, safety vest, and steel-toed boots. She happily drives off in a company truck to the landfill, lugging field parameter testing probes and a 10-pound ISCO to collect leachate samples; or do other fieldwork like locating LFG wells and pipes or other features that help her design.

In the summers, it gets scorching hot. And the winters can be bone-chilling cold, especially for a woman who spent most of her life in India, where she was born and raised. In her last years there, she studied the transport of heavy metals through groundwater. Then, it was on to the University of Texas, Arlington, where she earned her Ph.D. and became set on finding work at SCS, coming on board in 2019.

Among her earliest challenges was communication. “Sometimes I would be in a meeting or having lunch with my colleagues, and they would bring up baseball or other games or a Netflix series. They were new concepts to me, and I couldn’t relate. While I speak English, I was unacquainted with the vernacular. I was like, what is Super Bowl? I thought maybe it was something very big that people eat from,” she recalls. That does not stop a researcher.

Finding a way to become better acclimated became a project of sorts. She started spending weekend downtime in front of the TV to learn about these American pastimes. Baseball still isn’t her first love, but she’s happy to say, “In 2019, I went to my first Washington Nationals game with a big group from SCS, and I had at least some knowledge of what was going on.”

The ambitious civil engineer has pushed past another on-the-job challenge—one brought on by the impulse to know every detail she can nail down before setting to work. “Since I’m from a research background, I tend to dig to the very bottom to try and know the problem completely. Sometimes it’s a good thing. But I’ve had to be conscious of time constraints, gain an understanding of the minimum required to do the job well, and move on,” she says.

What first brought her to the United States was her husband, Ramesh Padmanabhan. He was working on a Ph.D. at the University of Texas at Dallas while she was studying in India, so the relationship truly began as a long-distance one. They got to know each other through a combination of old-world traditions and 21st Century channels. “Ours was an arranged marriage. Our parents introduced us, and for the first year, we met up and talked on SKYPE,” Dr. Iyer recollects. He’s a molecular and cell biologist and sometimes her consultant too.

“In my job, I need to know the biology and chemistry of microbes as they are responsible for breaking down waste, and he is my encyclopedia. I don’t have to Google as much when he’s around.” She adds: “I can’t complete my story without talking about my brother who has given me unconditional support and career advising through my life. These two men are pillars of my life.”

As a woman civil engineer who’s all about waste, she’s in the minority, but she doesn’t feel as if she is because women are moving into waste engineering. She’s one of four women on an eight-person team, who she says is “like my family. And my supervisor is a great supporter of women in STEM (science technology, engineering, and math).”

She hears from many newly degreed civil engineers, including “young ladies” with questions about waste management. They read blogs about her work that originated on SCS’s website and are on social media. “These graduates want to take their career to the next level, and they have a lot of questions about how to start solving waste issues,” she says. She tells them that solid waste management is one of the best and most stable industries they can choose and that the pandemic has driven that point home. “We are reminded through COVID that waste management is an essential business, and there will always be jobs to support it,” she says.

What Dr. Iyer loves most about her job is what she and her team imagine and draft in drawings, keeps developing, and in time, is built. “It’s like giving birth to a baby. Very exciting,” she says. Her groundwater contamination remediation work got her interested in PFAS, even before she finished her studies. “I had a lab mate in school who did PFAS research. That got me curious about these emerging contaminants. I’ve stayed vigilant to keep up with what’s happening with regulations and treatment options under research. If regulations now under consideration are implemented, our clients will have to start thinking more proactively about addressing PFAS. So, we need to learn more on a holistic level about what these contaminants can do and the best way to treat them.”

She tells the story of how her venture into civil engineering started with her father. “He wanted to be a civil engineer himself but was the eighth son, so his parents couldn’t afford tuition, and in India, you don’t go to college once you are grown with a family,” she explains. He wanted his daughter, already drawn to engineering, to pursue what had been his dream and said he thought it would suit her better than the direction she was leaning. “Had I studied mechanical engineering as I’d been thinking of doing, I would not have come into waste.” She is happy with where she’s landed.

“When you work all day and still are not tired –you still enjoy it and are happy to contribute to something good—that’s how you know it’s the right fit.”

In our newest SCS Advice from the Field, Ali Khatami makes his case for the landfill chevron pattern…

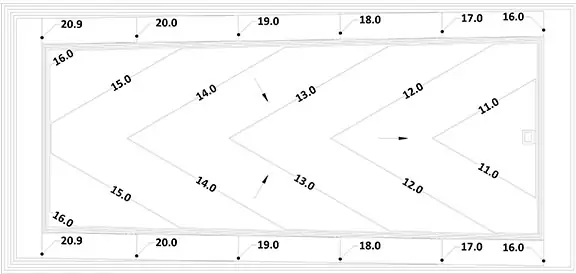

For at least the past 50 years, our industry has referred to the design pattern for the bottom of landfill cells as herringbone. But, it’s time to break the long-standing herringbone reign and give credit to the true holder of the crown: the chevron pattern. A chevron pattern visualizes the actual geometry used by landfill designers over the decades.

The schematic views of both patterns are shown below:

Now, here’s a sketch of a landfill single-cell design:

Note the cell base area with elevation contours that resemble the chevron pattern, with the leachate collection pipe located along the centerline of the cell. The cell base area is sloping toward the leachate collection pipe to convey landfill leachate at the base to the pipe, then the pipe conveys the leachate to the leachate sump located at the low end of the pipe. The pattern at the base can easily be duplicated in either direction of the cell area, developing a multi-cell design resembling the chevron pattern shown above.

In this case, the straight lines connect the low points (representing leachate collection pipes) and the high points (representing the divider berms separating adjacent cells). The zig-zag lines in the pattern remind landfill engineers of the elevation contours for the landfill bottom design geometry.

Meanwhile, with the herringbone pattern, the adjacent “tiles” or rectangular shapes are in a perpendicular position to each other and do not resemble the zig-zag lines in the chevron pattern. The herringbone pattern cannot be representative of the elevation contours, leachate collection pipes, and the boundary lines between adjacent cells like the chevron pattern. Additionally, the angle of line segments in the zig-zag in the chevron pattern can vary to any desirable value, which allows representation of changes to the disposal cell base slope (an important parameter in landfill design). On the contrary, the tile position in the herringbone pattern has to maintain perpendicular angles throughout and therefore it loses the ability to represent various base slopes.

One may draw lines along interface boundaries of the herringbone features and come up with the chevron pattern. But why stretch the truth when the chevron is already clearly the pattern? It is not apparent how or why the herringbone association took hold in the first place, but it’s about time that changed.

Admittedly, it took nearly four years to scientifically support the validity of the Special Relativity Theory from the time it was published by Albert Einstein in 1916. And it took nearly 50 years to physically detect the existence of Higgs boson particle from the time it was theorized by Peter Higgs in 1964. So, I suppose we can wait for formal recognition of chevron designation for landfill design.

Why such a big deal!?

The chevron validation may be insignificant compared to the scientific validations of Einstein’s and Higgs’ work. For landfill engineers, attune to details, it could be considered big because anything new, and more accurate in the landfill design field is a cheering matter!

Throughout the history of science, new findings supported by scientific evidence have replaced prior theories or concepts when progress is desired. Change of the pattern association, in this case, may not qualify as a scientific finding; however, it is a clear and noteworthy correction to what landfill engineers have been using over the past many years.

About the Author:

State regulatory agencies normally require landfill slopes reaching final grades to close within a certain period. This requirement leads to closing landfill slopes in phases, normally referred to as partial closure. Generally, partial closures start from the bottom of the landfill slope up to a certain elevation, with geosynthetics in the final cover temporarily anchored along the partial closure’s sides and upper boundary. Engineers propose different designs for securing the lower boundary of partial closures at the bottom of the landfill slope. Some engineers propose an anchor trench outside the bottom lining system anchor trench to secure the final cover geosynthetics. Others specify welding the cover geomembrane to the bottom lining system geomembrane.

Experience with anchor trenches at the bottom of the landfill slope for the final cover geosynthetics has not been positive because of these issues:

To eliminate the issues above, engineers weld the final cover geomembrane to the bottom lining system geomembrane for cases when there is a bottom lining system below the waste. The welding completely seals the landfill interior space from the outside environment and keeps regulated materials, such as waste, leachate, and gas, within the sealed system. Of course, the engineer should design proper means to address these behind the sealed system; designs may include:

Leachate toe drain system is a concept originally developed by SCS and incorporated into landfill final cover designs over the past 20 years. Unfortunately, many solid waste engineers are unaware of the need for LTDS, so their designs lack this important feature. LTDS saves a tremendous amount of repair money in the long run by avoiding complications for landfill operators.

A rainwater toe drain system removes water that moves laterally within the final cover geocomposite toward the slope’s bottom. The RTDS includes a perforated HDPE pipe encased in gravel and wrapped in geotextile. Also, install the RTDS on terraces along the depression on the interior side of the terrace. Along the landfill slope’s bottom, position the RTDS behind a HDPE flap welded to the final cover geomembrane. The RTDS is sloping with high and low points along the RTDS alignment. Lateral drain pipes located at low points remove water from the RTDS to the perimeter ditches.

Other designs involving extending the geocomposite to daylight at the slope surface cause problem such as those listed below:

Similar issues can also occur at the outlet of such systems on landfill terraces, making the RTDS a superior design.

About the Author: