See SCS Engineers Health and Safety Services

EPA has revised the PM2.5 ambient air quality standard, and in addition, the nonattainment status for ozone is changing in certain areas of Wisconsin. How will these changes impact your facility and future permitting?

Join SCS Engineers as a Platinum Sponsor at the 40th Annual Environmental Training Symposium & Conference, held in-person at the San Diego Convention Center. This conference includes 25 educational sessions on three tracks running simultaneously over two days, May 13th-14th. The conference hosts a robust Exhibit Hall, an Awards Luncheon, and a San Diego Bay Yacht Cruise. Panels will cover topics including air, hazardous materials, health & safety, sustainability, and water quality, with expert speakers from Southern California.

Register today!

Meet SCS Engineers professionals at BOOTH 619 at the Wisconsin Safety Council’s 2023 Annual Conference April 17-19 at the Kalahari Resort in the Wisconsin Dells.

This is Wisconsin’s premier event highlighting health, safety, and human resource best practices challenges and solutions. The conference features over 50 educational sessions, 200 exhibitors, and 6 pre-conference professional development courses. CEUs will be available. In its 81st year, the conference provides a unique opportunity for professionals to share resources and experiences with colleagues, and to discuss views and concerns with a wide range of stakeholders. You will hear from top-notch speakers and attend sessions with the latest safety information.

Featured Speaker Travis Mills, Retired United States Army Staff Sergeant of the 82nd Airborne, will make you laugh, cry, laugh some more, and stand up and cheer as he shares his astonishing story of survival and unending service. One of only five quadruple amputees from the war in Iraq/Afghanistan, Travis is the NY Times Best-Selling Author of ‘Tough As They Come’ and one of the most critically acclaimed inspirational speakers in the world. A master of the one-liner, Travis’s infectious humor illuminates this remarkable story of resilience and overcoming adversity.

Keynote Speaker Glen Tellock, Retired President & CEO, Lakeside Foods & Manitowoc Company, will provide “A CEO’s Perspective: Building Successful Teams & Instilling a Culture of Safety”. Glen spent three decades in leadership positions with a leading food processor and a manufacturer of construction equipment, and he knows that a strong culture of safety must come from the top. In a fireside chat, Glen will discuss his years as CEO, the challenges he faced, and how he overcame them. Glen will also address the need executives to lead by example when developing a world-class culture of safety.

Click for conference details and registration information. We hope to see you there!

Suzanne doesn’t stop there; she continually evolves her programs and participates in association speaking opportunities to share successful strategies throughout North America at Solid Waste Association of North America (SWANA) events and others. Her focus has been proactively identifying hazardous landfill and landfill gas situations and presenting unique and successful solutions she has developed for SCS. But, as the number of MRFs and Transfer Stations is expected to increase, those areas have become safety focus areas.

The industry is seeing a reduction in workplace fatalities based on the most recent U.S. Department of Labor’s Bureau of Labor Statistics, but there is more work to do. “Solid waste is a dangerous industry, and we collectively work to bring awareness to those most vulnerable to injury or worse,” said Sturgeon. “As an industry, we have the tools and more on-demand training to help reach more workers before problems occur to continue making our industry safer.”

As the SWANA National Safety Committee Chair, Suzanne is working hard and smart in the field, keeping up with new systems, equipment, and facilities that need her particular skills and insight to keep worker fatalities and injuries on the downward trend. Her innovative training and ability to communicate with so many saves lives.

Greg’s 35 years of experience include operations, project management, design, permitting, regulatory support, construction oversight, system start-up, economic analysis, and technology assessment to find the right system and the proper mix for sustainable composting operations.

Among his successful innovative projects, there are award winners for demonstrating composting operations can be in urban areas, conveniently coexisting with buildings and people, even tucked under a bridge in New York City.

He created an Aerated Static Pile (ASP) composting pilot program so that municipalities and businesses could evaluate their organic waste streams to determine whether composting is a viable solution before making a capital investment.

And he is leading the design of hybrid composting approaches that combine an ASP system with other technologies, such as open windrows. These hybrid systems can achieve necessary process control while maintaining cost efficiencies. The designs depend on the priority challenges unique to each project — processing increasing tons of food scraps, for example, but change as priorities differ within programs. Sustainability means the systems are flexible enough to adapt to waste trends and the end market, which demands various high-quality mixes to sell.

Greg says, “the advancements mentioned above help support sustainable composting and organics management because they account for changes that may occur over the life of the systems, such as waste characteristics and their relation to the end-product demand.”

In his latest article, Bill Lape reviews IIAR safety compliance and provides best practices. Eyewash/shower units should be within 55 feet, but that can feel like a long way if there are obstacles or hurdles to reach it.

Read his article, and review your plant or machine shop.

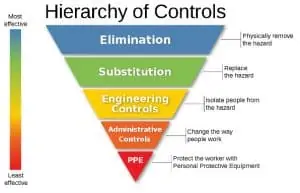

According to the Occupational Safety and Health Administration (OSHA), National Institute for Occupational Safety and Health (NIOSH), and the World Health Organization (WHO), noise is a serious health concern in the 21st century. Although Personal Protective Equipment (PPE) is seemingly the least expensive and simplest control for noise, PPE is also the least effective. It relies on personnel to utilize the correct PPE at the appropriate times.

Approximately 22 million workers are exposed to hazardous noise levels each year in the United States, and over 10 million US workers have diagnosed Noise-Induced Hearing Loss (NIHL). (1) Industries with high numbers of workers exposed to loud sounds include construction, agriculture, mining, manufacturing, utilities, transportation, and the military. Excessive noise can lead to a range of health problems for all citizens, but a growing number of non-industrial workers, including restaurant and school employees, are experiencing this irreversible occupational hazard.

Noise in U.S. industry is an extremely difficult problem to monitor, acknowledges Craig Moulton, a senior industrial hygienist for OSHA. “Still,” he says, “OSHA does require that any employer with workers overexposed to noise provide protection for those employees against the harmful effects of noise. Additionally, employers must implement a continuing, effective hearing conservation program as outlined in OSHA’s Noise Standard.”

Sounding Out Realistic and Effective Solutions

SCS Engineers Industrial Hygienists utilize the hierarchy of controls when developing solutions that involve elimination, substitution, and engineering controls as the first steps to controlling excessive noise. Only when a solution cannot be identified or implemented from these controls do we look to administrative controls and PPE.

“When we design our investigations and remediation plans to address specific noise issues, we are also sensitive to the costs associated with expensive analytical testing,” states Jed Douglas, Industrial Hygiene National Expert. We find cost-effective and lasting solutions by:

SCS has completed numerous noise investigations and sampling for various facilities, such as schools, offices, warehouses, industrial and commercial buildings. SCS’s Industrial Hygienists help building owners, facility engineers, property managers, attorneys, insurance companies, and municipalities with investigations and remediation of the factors contributing to excessively loud noise, including area sampling and surveys of personal exposure for regulatory compliance. We can also help with hearing protection programs, medical monitoring programs, and the selection of PPE.

Additional Information

Noise pollution, also known as environmental noise or sound pollution, is the propagation of noise with ranging impacts on human or animal life activity. Machines, transport, and propagation systems mainly cause outdoor noise sources worldwide, including highways; construction activities; urban congestion; power generation; public transportation, recreational vehicles, home power tools, yard maintenance, and air cooling equipment.

Common sources contributing to harmful industrial loud noise:

Health effects from loud noise include:

During this COVID-19 outbreak, many employers, property managers, and property owners are tirelessly working to maintain clean and safe environments for tenants and employees. Cleaning contractors and janitorial services are working overtime, expending considerable efforts trying to maintain clean and disinfected workspaces and buildings. While providing their services, they face continual challenges of not having enough information regarding COVID-19 behavior, and the dwindling supply of cleaning and disinfecting agents. Many have inquired about microbial sampling and analytical methodologies to evaluate the effectiveness of these cleaning measures.

Some of us have been here before. Twenty years ago, property managers and tenants faced similar challenges in the wake of anthrax contamination of mailrooms in several prominent buildings. The approach we took then—collecting wipe samples from areas of concern for analysis at a nationally-recognized specialty laboratory—can offer peace of mind and an empirical basis for the evaluation of cleaning/disinfection effectiveness.

While specific testing for viruses, including the novel coronavirus (SARS-CoV-2), is not generally available, it is possible to test environments and surfaces for the presence of surrogate clinical pathogens and bacteria—these should be absent if cleaning and disinfection are effective.

Every building, tenant space, and office work environment is unique, and therefore it is important to develop site-specific plans. Staff collecting the samples should be trained in hazardous incident response, including microbiological and chemical impacts on structures and the environment, and should have the proper personal protective equipment (somewhat scarce at present in many locations).

About SCS Engineers

SCS Engineers is a 50-year-old, employee-owned environmental consulting and contracting firm that designs and implements sustainable and innovative environmental solutions. With 70 offices nationwide and nearly 1,000 employees, we are a full-service provider in the solid waste, hazardous waste, and environmental engineering industries. We study challenges and design solutions; we remediate, build and operate environmental and energy projects and systems; and, we evaluate the public health risk of hazardous materials exposure scenarios. As technologies, industry, and public needs change and expand, SCS evolves to provide innovative solutions to our clients’ challenges.

Most states’ guidance considers SCS’s services as essential to protect public health.

Contact SCS today at 800-767-4727 or for additional information and consultation regarding the effectiveness of cleaning/disinfection at your properties and workspaces in your state. Further information about SCS is on our website at https://www.scsengineers.com/.

Both associations are providing guidance, as many waste management activities must continue. SCS is following association advice, state protocols, and our clients’ recommendations in our own procedures as we continue to perform essential work. We share the SWANA resources and recommendations here and thank them for their dedication. SCS employees should use SCS resources available on the SCS intranet and through our Health & Safety protocol, which reflect the safety precautions advised here.

Reprinted Letter to SWANA Members dated March 23, 2020

As communities and companies throughout the United States and Canada respond to the Coronavirus pandemic, SWANA will continue to provide assistance to its members and the waste industry.

A growing number of states and localities are issuing orders identifying certain industries as “essential” during the pandemic, and these orders typically include the solid waste industry and other categories of employees who may be SWANA members. In those locations, employees and contractors may need to demonstrate proof to law enforcement personnel or others that they work in an essential industry. See this template letter that employers can customize to their needs and provide to employees and contractors. The letter should be on agency/company letterhead and include a contact person and a telephone number to call. The contact person should be familiar with the applicable emergency declarations.

Employees and contractors should carry the customized letter with them at all times, and particularly when they are going to or from work. Several waste industry employees in California in their personal vehicles were stopped on their way to work by law enforcement personnel late last week, but fortunately, their employer had created a letter similar to the attached and the employees were able to show that letter and proceed to their places of employment.

This letter is intended to allow workers to demonstrate that they work in a job category identified as an essential service, including solid waste and recycling operations. It should not be used for any other purpose or by employees that are not actively supporting these operations.

In addition, attached is a notification document for solid waste employers and others to place in their work vehicles to demonstrate they are covered by recent emergency order guidance. It cites the Department of Homeland Security’s Cybersecurity & Infrastructure Security Agency, March 19, 2020 memo that identifies workers engaged in the removal, storage, and disposal of residential and commercial solid waste and hazardous waste as essential infrastructure workers.

Please do not hesitate to contact Jesse Maxwell at or me at if you have any questions about this letter, or need assistance responding to the Coronavirus pandemic. Please stay safe and healthy.

NWRA resources are plentiful and include these:

COVID-19 WORK PRACTICES At this time CDC and OSHA are not issuing waste and recycling specific guidelines for the handling of waste and recycling materials related to COVID 19. If this changes, NWRA will alert its members. Use this industry guidance.

COVID-19 RESOURCES Resources and information provided by agencies and organizations.

Thank you!

In light of public concerns related to COVID-19, SCS Engineers has proactive measures and contingency plans in place to protect our employees and our clients, while continuing our work. SCS’s Health & Safety practice, in consultation with our executives, the Centers for Disease Control, and industry associations, endeavors to make the most responsible decisions as circumstances demand.

SCS will post updates here as needed, and is in regular and consistent communication with all employees and with our clients.

Can Computer Technology Enhance Safety and Environmental Protection?

Just when you thought we had gone as far as we could, now there is remote monitoring and control technology. Did you know that you can have live access to monitor equipment and data in real time from your living room? You can see how fast pumps are running or what temperature or flow rate you have at your flare. You can access live video feeds from cameras and actually see inside your flare station or storage area. Notification of unplanned shut downs can be set up. You can be notified on your mobile device when something goes wrong. The technology exists to remotely start flares when they shut down. Imagine eliminating a three-hour drive to restart a flare. Not only do you save time and money, but you avoid a potential environmental impact or fine. This is cool stuff.

Remember, whatever technology you use or plan to use, make it user-friendly. Most people resist change, and the ability to use technology varies among employees. Generation X’s and Millennials tend to understand and use computers and mobile devices more effectively than some Baby Boomers. If you want your technology to work for everyone, take a slow and defined approach to implementing the use of technology. Provide training to explain what the benefits are, and how to do things step by step. Develop written procedures that can be accessed when people become confused or forget how to do things. These measures will help others welcome the introduction of technology in the workplace. Set employees up for success. Identify employees that are well suited to use technology, and consider empowering them to assist others. As technology use grows, develop IT positions to support your efforts.

Technology is continually improving; this is a good thing. Despite these advances, try to monitor the changes you make. Try not to fall victim to continually changing the way things are done. Allow time for people to understand and use the tools they have. Consider user abilities and develop updates that are necessary or enhance your process. Include end user employees in the technology development process. Keep in mind that technology, in most instances, solid waste industry included, should support workers and operations, and not the other way around.

Contact Michael Knox or continue to read his entire article here.

Technology in the solid waste and landfill gas industry.

About Michael Knox

For over 30 years, Mr. Knox has participated in projects ranging from clearance of unexploded ordnance (UXO) from military impact ranges to construction and management of waste treatment and disposal facilities. Currently, he performs compliance audits of SCS operations. His experience in environmental safety, construction, and remediation is exceptional in terms of both field and administrative application. He often serves as the primary interface between federal, state, and local regulatory agencies and SCS project teams.

In addition to his work as a compliance auditor, Mr. Knox is a Project Manager in Florida. In this role, his responsibilities include the execution of contracts, plus management oversight and coordination of all field operations; including landfill gas collection systems at numerous landfills.