Great innovations take shape when people with shared ambitions, high energy, and creative juices pool their talents and gusto. Meet two professionals at SCS Engineers, who, through their mutual entrepreneurial spirits, found a resourceful way to create landfill efficiencies for operators — saving time and money. Here’s the story of Chris Carver and Joy Stephens — and a service they helped develop, leveraging cutting-edge technology that’s been a game changer for landfill efficiency.

Chris Carver joined SCS Engineers soon after coming out of the military, where he served as an infantry soldier, protecting our country from threats on the ground. Brand new to landfill operations, the now 17-year SCS veteran started out dropping pipes and installing gas collection and control system (GCCS) components.

“But I was hungry to know how all the pieces fit together. I wanted to understand what made these complex systems work and everything they could do,” Carver recalls.

The more he asked, the more he learned, and with that knowledge came new opportunities. He climbed from laborer to field technician to landfill project manager. And, finally, to tech guru, building and managing powerful databases.

Not long after he’d moved into the IT space, Carver met Joy Stephens; a teacher turned environmental scientist who also did some data processing. They would enter a working relationship about shared learning and feed on each other’s curiosity and knowledge. Their synergy would play a key role in SCS’s GIS services integration with SCS RMC®. By leveraging GIS technology, the duo created site-specific, detailed digital maps that enable operators to visualize what’s happening in the field in real-time. Landfill and environmental staff are continually informed, allowing immediate action when needed. The operation is supporting about 117 patrons around the country and growing quickly.

Carver and Stephens met while working at a Tennessee landfill.

He oversaw field operations, monitoring and managing liquid levels, gas extraction wells, and surface emissions. And he was facilitating the transition to a digital platform to manage and use the field data better.

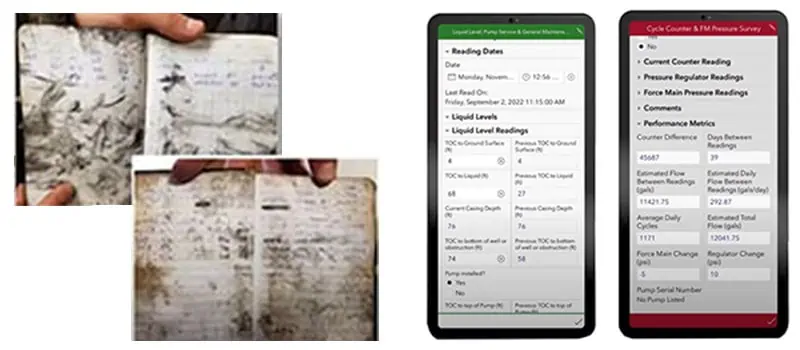

Stephens processed the data and helped him prepare operations, monitoring, and maintenance reports, which Carver used to identify trends and determine how to improve field operations. She generated those reports mainly from the field tech’s handwritten notes in those days.

In between their office dialogues, Stephens would follow him into the field, curious to see how he and the landfill techs worked.

“We began talking about how we could collect more and different types of data and use it to make the field techs’ and operators’ jobs easier while boosting their efficiency,” she says.

Plenty has transpired since those early conversations, and they continue to take their work further, dedicated now to SCS’s GIS Services, launched under the company’s Remote Monitoring Control Group.

Today, Carver and Stephens make digital forms and maps –Self-Monitoring Analysis and Reporting Technology (aka SMART)—the smartest they can be.

As the system grows in sophistication, clients tap into more information, in more detail, on GCCS, liquid management, and other landfill operations.

Stephens’ bailiwick is creating the smart forms field techs fill out from an app and upload to the cloud, replacing those cumbersome logbooks they used to lug, then bring to her. She also designs maps that connect to and pull information from the forms to visualize the information. She’s a mavin at capturing specific data points that operators look for and formatting the maps to deliver easy-to-read visuals of a lot of information.

Carver’s job is to manage the behind-the-scenes workings of the software to ensure the smart forms and maps perform as designed. There’s a lot of organizing and processing that goes on.

It requires fluency in multiple programming languages to customize functionality for each client. He may need to build in constraints and immediately visible liquid level calculations, write scripts to pull meteorological data from a weather station into a smart form, or script to automate tedious tasks such as parsing temperature probe data.

Stepping back in time, Carver says, “When Joy and I started working together, I was the Google maps guy. I incorporated data in Google maps to guide the field techs to the site locations needing their attention. Then Joy said, have you heard of GIS?”

It was more sophisticated. It could pick up on site-specific details that Google maps couldn’t.

“She showed me how the mapping and visualization worked. We could see liquid column heights in gas wells, fluctuating gas quality, and other actionable details. We would actually be able to monitor the overall health of each well and multiple other operations. I fell in love with it,” Carver says.

That’s when Stephens began creating maps connecting to the digital forms she’d been developing, allowing Carver to identify where to focus quickly.

“It helped me increase efficiency in the field, and our projects gained traction,” he says.

Stephens, like Carver, continually seeks to know more.

“In those early days when I went out in the field with Chris, I’d ask a ton of questions to understand better what information to capture and incorporate into the forms. Why are we monitoring this? What constitutes good gas quality? Why is it important to know liquid levels?” Stephens reflects.

They were the same questions Carver had asked years before, and he was impressed.

“I wanted a smart, curious partner who would move things along. And that is Joy,” says the equally curious and ambitious techie who taught himself how to code when building a website for his son’s baseball team.

As colleagues and friends, they have taken GIS capabilities beyond monitoring and analyzing field conditions. Now the system connects to IoT technology, enabling operators to take action remotely, whether increasing or reducing gas flow or turning dewatering pumps on or off, among measures.

They have mastered another skill set to capture and layer in more data. They’ve become drone pilots, flying unmanned aircraft over landfills to record methane emissions-related information from locations hard or unsafe to reach by foot.

As co-pilots, they share another interest beyond teaching, learning, and making technology do what they want.

It’s a time to experience their mutual affinity for the outdoors, take in their surroundings, and reassert that what they do is more than worthwhile.

“The top deck of the landfill, where Joy and I do our drone flights, is one of the most beautiful places. Depending on the part of the country, you see the woodland and mountains for miles. And get spectacular views of the town,” Carver says.

Stephens recalls an especially memorable flight on the East Coast getting methane emissions readings.

“We were gazing upward, and a pair of bald eagles on the landfill were soaring above us. It was one of those moments where we just looked at each other in awe.”

Later they talked about how that moment reminded them of what they do and why they do it.

“There is this incredible world around us. In responsibly managing landfills, with their important role in keeping communities clean and capturing climate-impacting methane, we help to preserve that world,” Stephens says.

Carver chimes in: “I think sometimes people lose sight of the fact that when we are gone, we leave this planet to our kids. Whatever we can do to improve it for them and their kids … that’s a good motivator for me.”

Click to learn more about

Click to learn more about environmental careers at SCS Engineers.

Join SCS’s next educational forum on remote monitoring and control technologies.

The Young Professionals Planning Committee (YPPC) recently got together in Long Beach, California, for our annual meeting. During the meeting, we set goals for 2023, laid out the 2023’s calendar of events, elected new officers, and participated in team-building activities. Team building activities included reviewing our DiSC profiles, tower building focused on cooperation and communication, and a cooking class, whipping up So-Cal favorites with Mexican-themed dishes. The meeting kicked off the new YPPCs tenure, consisting of 13 members from 8 business units representing our Young Professionals across the nation.

The SCS Young Professionals Program was established years ago and includes all employees at SCS Engineers who are 40 years of age and under. The YP Planning Committee produces the Program content and acts as a liaison for the Program between SCS YPs, corporate leadership, and at Board of Directors meetings.

Our membership is spread across various regions of the country to represent the entire company.

We offer a variety of resources and activities for all YPs, including:

For more information check out these pages: