Article by Cheryl Moran, CHMM

Technological advances in traditional printing and the advent of digital printing can make it more challenging to know when you need an air permit and which permit is best for your operations.

There are two main activities that may trigger air permitting – construction and operation; each of these comes with its own permitting requirements. Always check to see if you are required to apply for a construction permit before bringing new equipment on site. Once a source is installed, an operating permit will be necessary, which is the focus of this article.

Federal Title V operating permits (also referred to as Part 70 permits) are required for any facility that is considered a “major source” of air pollution. For purposes of operating permits only[1], a major source is a facility that has the potential to emit (PTE) more than 100 tons per year (tpy) of any criteria pollutant; volatile organic compounds (VOC), carbon monoxide (CO), nitrogen oxides (NOx), sulfur dioxide (SO2), particulate matter less than 10 microns (PM10), or more than 10 tons of any individual hazardous air pollutant (HAP) or more than 25 tpy of combined HAPs . Permitting thresholds are lower for facilities located in non-attainment areas.

Some facilities take limits on material throughputs, hours of operation, or emissions in order to artificially lower their PTE to qualify for a Federally Enforceable State Operating Permit (FESOP). These permits are also called “synthetic minor” permits.

Facilities that do not exceed federal permitting thresholds may still need to acquire a state operating permit. State permitting programs have more options than ever before and several states are summarized below.

ILLINOIS:

All “emission units” are required to secure an air permit, or register with the Illinois EPA, even very small sources of air pollution. An “emission unit” is any piece of equipment located at an emission source that has a potential to emit air pollution. Registration of Smaller Sources (ROSS) is for operations that emit less than 5 tpy of combined criteria pollutants. Sources with a potential to emit more than 5 tpy, but whose emissions are less than the threshold for a FESOP, may qualify for a “life-time” operating permit.

Visit for more information on the Illinois EPA permitting program.

WISCONSIN:

ROP Type A Registration Permit is for facilities with actual emissions of less than 25 tpy for criteria pollutants and 6.25 tons per year for HAPs.

ROP Type B Registration Permit is for facilities with actual emissions of less than 50 tpy for criteria pollutants and 12.5 tpy for HAPs.

ROP C Registration Permit for Printers is only available to printers. To qualify for this permit, emissions of each criteria pollutant are limited to 25 tons per year, and HAPs are limited to 12.5 tons per year.

General Operation Permit (GOP) for Printers applies to digital, screen, lithographic web printing (both heatset and coldset), and lithographic sheetfed printing.

INDIANA:

Source Specific Operating Agreement for Surface Coating or Graphic Arts Operations is available to printers with total VOC and HAPs that do not exceed 15 lb/day (7 lb/day in select counties).

Permit by Rule may be used for facilities that qualify for an operating agreement with criteria pollutant and HAP emissions that do not exceed 20% of the major source limits.

Find more on the Indiana permit options at http://www.in.gov/idem/airquality.

Whether you are applying for a state operating permit, or a federal operating permit, all applications will go through your state environmental regulatory agency.

[1] For construction permitting purposes, the thresholds that define a “major source” are typically higher than the operating permit thresholds.

For more information contact Cheryl Moran at SCS Engineers, Wisconsin or Ann O’Brien at SCS Engineers, Illinois, or for an SCS professional in your state.

Cheryl Moran is a Project Manager with SCS Engineers with more than 20 years of experience in the printing industry. She is a Certified Hazardous Materials Manager (CHMM) and has worked with air, water, and waste issues including permitting, environmental recordkeeping, reporting and monitoring programs, hazardous waste management, environmental compliance audits, and sustainability programs.

Ann O’Brien is a Project Manager with SCS Engineers. During her 32-year career in the printing industry she was responsible for environmental compliance programs, including, but not limited to, air and water quality permitting, environmental recordkeeping, reporting and monitoring programs, hazardous waste management, environmental compliance audits, and environmental site assessments and due diligence associated with real estate transactions and corporate acquisitions.

Author: Ann O’Brien

Alert: Toxic Release Inventory Form A and Form R Reports were due July 1, 2016

The Toxics Release Inventory (TRI) was created by EPA in response to several events that raised public concern about local preparedness for chemical emergencies and the availability of information on hazardous substances.

Printing is one of the industry sectors required to annually report releases of certain chemicals. A printing facility with 10 or more full-time equivalent employees is required to report if the facility exceeds established chemical thresholds. Note that TRI reporting is not based on the amount of emissions to atmosphere or how much waste is generated. Instead, a company that manufactures or processes more than 25,000 pounds or otherwise uses more than 10,000 pounds of a TRI-listed chemical were required to report releases of these chemicals by July 1, 2016.

There are currently over 650 chemicals covered by the TRI program including chemicals commonly used by printers, such as toluene, xylene, ethylbenzene, 1,2,4-trimethylbenzene, glycol ethers, solvents, and metals. Of particular interest to lithographic printers is the wide use of glycol ethers in fountain solutions and more recently in cleaning solutions, to take the place of solvents with high vapor pressures. It is important to mention that “glycol ethers” is a chemical category and within this category there are hundreds of individual chemicals that are reportable. Safety Data Sheets (SDS) do not indicate the presence of “glycol ethers” as a constituent of a raw material so a printer must look up each listed constituent and compare it to the list of TRI chemicals to determine whether is it reportable.

For more information, contact Ann O’Brien () or Cheryl Moran () at SCS Engineers.

Ann O’Brien is a Project Manager with SCS Engineers. During her 32-year career in the printing industry she was responsible for environmental compliance programs, including, but not limited to, air and water quality permitting, environmental recordkeeping, reporting and monitoring programs, hazardous waste management, environmental compliance audits, and environmental site assessments and due diligence associated with real estate transactions and corporate acquisitions.

Cheryl Moran is a Project Manager with SCS Engineers with more than 20 years of experience in the printing industry. She is a Certified Hazardous Materials Manager (CHMM) and has worked with air, water, and waste issues including permitting, environmental recordkeeping, reporting and monitoring programs, hazardous waste management, environmental compliance audits, and sustainability programs.

SCS periodically prepares technical bulletins to highlight items of interest to our clients and friends. These are published on our website. This SCS Technical Bulletin addresses:

Read and share the SCS Technical Bulletin here.

SCS Coal Combustion Residual Services

Do you have NSPS or EG sites per the new definitions of “new” and “existing”?

Does your EG site have any upcoming planned or permitted expansions, or will it be commencing construction on an expansion permitted after July 17, 2014?

Will you need to submit/resubmit Design Capacity and NMOC reports to establish your sites status as subject to the new NSPS? Over, or under 34 Mg/year of NMOCs?

Are you a candidate for Tier 4? In the closed landfill subcategory?

For EG sites contact the SCS state representative by sending a request to

SCS Engineers will be publishing Pat Sullivan’s Technical Bulletin Summary of Final NSPS/EG Rules for Landfills as soon as it is published in the federal register. Meanwhile, please contact your SCS Project Manager or for answers to your questions or advice. Follow SCS Engineers on your favorite social media site or check our events for new presentations, publications, and webinars explaining the rules in more detail.

On July 11, 2016, multiple organizations representing the full value chain of cellulosic waste feedstock conversion to transportation fuel sent a letter to Gina McCarthy, Administrator of the U.S. Environmental Protection Agency (EPA). The letter supporting the Renewable Fuel Standard Program: Standards for 2017 and Biomass-Based Diesel Volume for 2018 (Proposed Rule) noted that additional information and factors need to be considered.

Read or share a copy of the letter here, contact SCS Engineers, or one of the organizations below:

SCS Engineers has published two Technical Bulletins summarizing the O&G NSPS final rule and outlining the new LDAR requirements. The two Bulletins explain the modification of how oil and gas sources will be permitted under the Clean Air Act and the new requirements to reduce methane leaks from new oil and gas facilities consistent with the EPA’s New Source Performance Standards.

Reference the U.S. Environmental Protection Agency (EPA) new source performance standards for Crude Oil and Natural Gas Production, Transmission and Distribution (O&G NSPS), which includes amendments to 40 CFR Part 60, Subpart OOOO and a new Subpart OOOOa. Subpart OOOOa will apply to facilities constructed, modified or reconstructed after September 18, 2015.

Click to read or share the Technical Bulletins:

https://www.epa.gov/controlling-air-pollution-oil-and-natural-gas-industry

Pat Sullivan, REPA, CPP, BCES

(916) 361-1297

The Environmental Protection Agency (EPA) has recently proposed increases in renewable fuel volume requirements across all types of biofuels under the Renewable Fuel Standard (RFS) program. The proposed increases would boost renewable fuel production and provide for ambitious yet achievable growth.

The Clean Air Act requires EPA to set annual RFS volume requirements for four categories of biofuels: cellulosic biofuel, biomass-based diesel, advanced biofuel, and total renewable fuel. EPA implements the program in consultation with the U.S. Department of Agriculture and the U.S. Department of Energy.

EPA will hold a public hearing on this proposal on June 9, 2016, in Kansas City, Missouri. The period for public input and comment will be open through July 11, 2016.

For more information on the proposal, see www.epa.gov/renewable-fuel-standard-program/proposed-renewable-fuel-standards-2017-and-biomass-based-diesel.

For more information on the public hearing, see www.gpo.gov/fdsys/pkg/FR-2016-05-25/pdf/2016-12358.pdf.

An SCS Engineers Technical Bulletin will be released early in the week.

The U.S. Environmental Protection Agency issued limits on methane emissions from oil and gas wells that are more stringent than those it proposed last year. The final regulations released on Thursday, May 12, 2016, will add hundreds of millions in additional costs per year; at least 25 percent higher than the preliminary version published in August 2015.

EPA Administrator Gina McCarthy told reporters on a conference call that the mandates, applying immediately to new and modified wells, are a “critical first step in tackling methane emissions from existing oil and gas sources.”

Under the rule, companies must upgrade pumps and compressors while expanding the use of “green completion” technology meant to capture the surge of gas that can spring out of newly fracked wells. Such green completion techniques have been required for new and modified natural gas wells since 2015, but Thursday’s rule would broaden the requirement to oil wells too.

Take me to the EPA summaries. Click on the information sheets listed below:

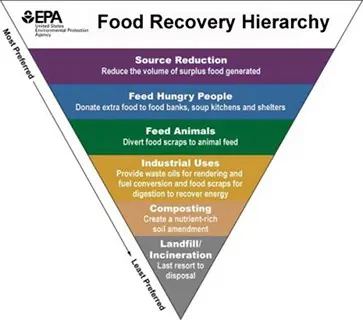

The Solid Waste Association of North America (SWANA) Applied Research Foundation released a report concluding that: a significant amount of additional food waste processing capacity will be required to achieve national, state, provincial, and local food waste diversion goals. The report also emphasizes the need for local decision-making in selecting and implementing those food waste diversion programs.

…a significant amount of additional food waste processing capacity will be required to achieve national, state, provincial, and local food waste diversion goals. The report also emphasizes the need for local decision-making in selecting and implementing those food waste diversion programs.

The report goes on to say that interest in recovering food waste from municipal solid waste is growing to meet goals established by the U.S. Environmental Protection Agency and U.S. Department of Agriculture, but many major metropolitan areas lack the infrastructure to manage the ability to meet the established goals. Two examples were cited:

Several states, including Massachusetts and Connecticut, condition their food waste diversion requirements on the ability of generators to access adequate capacity within a certain distance.

Speaking as SWANA’s Executive Director and CEO David Biderman stated:

We believe that Americans need to rethink how food is handled before it is considered waste, to divert it into programs to feed people, and to find other productive uses for food as food. Once it becomes waste, however, municipal decision-makers, working with their processing partners, need to determine how to best manage the material.

The SWANA report focuses on the effects of food recovery at the two lowest tiers of the hierarchy – composting and landfilling/incineration. The report concludes that food waste diverted from landfill operations has the potential to be processed at composting facilities. Then, going on to say that anaerobic digestion (AD) and co-digestion at wastewater treatment facilities are also likely destinations for diverted food waste.

Jeremy O’Brien, Director of the Applied Research Foundation, noted:

The food recovery hierarchy does not apply universally; an analysis of greenhouse gas impacts based on local data and conditions is needed to identify the best food scraps management options for a specific community.

The report encourages solid waste managers to perform a life cycle analysis of economic and environmental costs and benefits based on local needs, system capabilities, and data to identify the most effective ways to manage food waste at the local level.

SCS Engineers and SWANA are both long-time advocates for local decision-making in establishing programs to collect and manage municipal solid waste.

Related articles:

Long story short, an escapee from San Quentin and any uncontrolled methane air molecule may be more similar than we may presume. In fact, a common LDAR practice is to use an infrared imaging camera; similar to the camera often used in search of fugitive criminals.

On a serious note, fugitive emissions are something that both industry and regulators have been focused on for decades, and the past and present efforts made to limit them are no less than remarkable.

Specific to Onshore Oil and Gas Exploration & Production, the Federal Regulations applicable to fugitive emissions are fairly young. Finalized in 2012, NSPS OOOO is no longer a toddler and is in the middle of growing into NSPS OOOOa (Public Comment Deadline March 11, 2016). On a national scale, NSPS OOOOa will expand fugitive emission monitoring and control requirements (VOC’s and methane) to several facility types associated with the industry and is expected to be finalized before the close of 2016.

In California, fugitive emissions from Onshore Oil and Gas Exploration & Production have been regulated for a long time. In fact, the O&G industry in Santa Barbara County has dealt with fugitive emission requirements since 1979. Since then SCS Engineers has been assisting with fugitive emission monitoring for our valued clients. Today, SCS Engineers provides the Oil and Gas Exploration and Production industry with efficient and effective LDAR services.

So fear not, SCS Engineers is ready to supply the knowledge and skill set you need to stay compliant, maintain your operations, and respect your bottom line. Remember, unless the doors are closed, pumps are turned off, and equipment is flushed and plugged; fugitive emissions requirements and LDAR will likely still apply.

Applicability: Determining Federal vs. State oversight is the first step. Non-Major Source Oil and Gas Production facilities are either subject to NSPS OOOO (soon to be OOOOa) or a related State specific rule (i.e. Colorado Regulation 7). Once oversight is determined, then there may still be exemptions for your facility (i.e. facility constructed before August 23, 2011). And finally, once regulatory oversight is confirmed and you determine that LDAR is required for your facility, then the last step is to figure out which equipment is applicable (i.e. VOC content > 10% by weight). Basically, an applicability determination can be daunting.

Equipment: EPA’s Method 21 is historically and currently referenced in all LDAR regulations. Method 21 requires an instrument such as the Flame Ionization Detector (FID) or Photo Ionization Detector (PID). More recently the Optical Gas Imaging (OGI) Camera has been included in LDAR regulations and utilized in LDAR programs. Presently, there are several instrument technologies that exist and are in the works, but not yet mainstream in Oil and Gas sector. Ultimately, if you were to find yourself conducting LDAR monitoring at your oil and gas facility tomorrow per an established regulation, you would most likely need to use an FID or OGI.

Recordkeeping: Personally, I like the simplicity of using paper forms for field notes; however, the old-fashioned way comes with risk. The up-front and ongoing data involved with an LDAR program is too much for maintaining a paper to computer process, regardless of how organized you think you are. Therefore, a computer database platform is recommended and necessary for managing your LDAR recordkeeping. Beyond just recordkeeping, a database platform can organize schedules, alerts, generate reports, extract trends, and many other applications to help keep your LDAR program compliant. One such platform worth considering is SCSeTools™. This cloud-based software can provide the database capabilities used on the desktop, but almost more importantly, provides mobile data input capabilities with the SCS MobileTools™ application fit for Android and IOS systems. Keep the fugitives from escaping, and document containment for the authorities!

Whether you want to discuss LDAR or Dodger baseball, don’t hesitate to contact me, or SCS Engineers.

Resources:

Learn more on the SCS service pages and read SCS project case studies from across the nation to help fine tune your program.

Outside links to the EPA proposed rulemaking website: