Landfill operators forever work to stay on top of a diverse and complex mix of leachate contaminants—heavy metals, ammonia, and biochemical oxygen demand (BOD), among them; but lately, they think about even more. For one: how to keep concentrations of these contaminants within wastewater treatment’ plant’s tightening discharge limits. Add to this concern the possibility of more compliance pressure as the constituents’ list on regulators’ radar grows. From microplastics to PFAS and PFOA, the latter sometimes called the “elephant in the room” –some operators are preparing for what may be down the pike.

Among strategies, some are looking at are on-site leachate treatment options, and there are several. Finding the most fitting, sustainable, and cost-effective one takes vetting. This continuing blog series explores studies conducted by SCS Engineers for operators nationwide. Here you will get an inside look at what these leachate management experts found, what treatment system they recommend in each scenario, and why.

A Solution to a Nebraska Landfill’s Rising Leachate Volumes

A Nebraska landfill needs to manage its rising volumes of leachate, causing disruptions to operations. The liquid goes into a 20,000-gallon tank, is pumped into a tanker, and is driven to the municipal wastewater treatment plant. The tank was filling so fast that the operator has trouble staffing and scheduling its few commercial driver’s-licensed operators to haul it. This logistical task has become a near-daily necessity. Sometimes the liquid level indicator will go off on the weekend. Management has to move quickly, sometimes on a dime, find someone to come in, and pay overtime.

“The staffing challenge is the main issue that brought the operators to SCS. They want to understand the whole leachate management structure better, and as we answer their questions, they want to know how we can improve the overall system in the long-term, says Zach Mahon, the SCS staff professional who works on the project. “After an extensive assessment, we provide options whereby the operator no longer has to pump leachate to a holding tank and then truck it to the wastewater treatment plant. And we provide site-specific recommendations to take their leachate management practices further,” he says.

Mahon and the SCS team of leachate management experts headed to the landfill to talk to operations staff and get their historical generation records, which is the basis they start with for their assessment. “We correlate the landfill information with our research to determine yearly generation figures as well as a peak generation number over the landfill’s projected life. This site is expanding, and we want to size the equipment so that when it reaches capacity, the system can handle the higher volume,” Mahon says.

SCS plans in other ways to ensure the recommended technology will take its client into the future on solid footing. For instance, accounting for the reality that operators may one day have to remove per- and poly-fluoroalkyl substances (PFAS) to send their multi-thousands of gallons of leachate to their wastewater treatment plant each year. Operators are keenly aware that utilities and regulators are looking with more scrutiny at PFAS and other emerging contaminants of concern.

Through due diligence, SCS engineers came up with three treatment options. Mahon explains each:

Install a leachate force main. This system includes a pipe with a pump that pushes the liquid through the force main, directly to the sewer line and, ultimately, to the municipal treatment plant. The pump kicks in automatically, negating the need to have drivers in the wings at all times. This system is quick to build and fairly simple to operate. It is the least expensive of the modifications that SCS vetted.

Install a leachate evaporator, which heats the liquids and evaporates the water molecules. This system reduces leachate volume by 90%. Managing liquids on-site eliminates dependency on drivers, but on the wastewater treatment plant too. The gas-fueled system is suited for sites with surplus landfill gas to help cut their operational costs.

Install a reverse osmosis treatment (RO) system where material passes through a membrane, which separates contaminants. RO treatment can reduce contaminated water by 90%, typically rendering it clean enough to discharge directly to surface water with appropriate permits. Or, it can be discharged to the city sewer, eliminating the permitting step.

“For each leachate treatment option, we looked at cost, the feasibility of short- and long-term implementation, and regulatory acceptance,” Mahon says. “We deliver the data with these priorities in mind, make our recommendations, and leave it to our client to decide.”

What did the SCS team recommend in this scenario?

“We suggested the force main. It solves the primary operational issue around staffing. And the economics of this comparatively inexpensive system make sense in these times when landfills are dealing with astronomical leachate management costs, among other increasing operating and capital expenses,” he says. This option does more than meet the client’s most immediate needs at a minimal cost. It provides the option to upgrade should regulators’ requirements around leachate change or should the wastewater treatment plant tighten its discharge limits. We design the modular system to add on reverse osmosis if necessary in the future. Thus, we help ensure that our client will continue having a home for its leachate.

A value-add, regardless of the operators’ decision, is more knowledge. SCS clients have a deeper understanding of industry standards. They are also more aware of how the industry is shifting in managing leachate and how these shifts could affect them. We follow up with technical bulletins explaining proposed and final federal rules in plain language influencing their operations, deadlines, and how to provide feedback to the appropriate agencies.

“We provide a lot of data to continuously inform our clients and to help them compare their operational costs now to what they would be if they invest in a new leachate management strategy. We ensure they fully understand each option’s capabilities to decide if it pencils out for their budget and operations. They have what they need to make informed decisions for a hands-off system to take them into the future,” Mahon says.

Leachate and Liquids Management

Cities like Oviedo, Fla. are investing in the cleanup of defunct brownfield sites, converting even highly contaminated properties from liabilities to assets that pump economic vitality into their communities. And municipalities are getting reimbursed for doing so. But these ambitious undertakings require the expertise of professionals with strong environmental engineering and remediation backgrounds and an understanding of federal and state regulations aimed to protect public health and the environment.

This spring, after over two years of working closely with SCS Engineers and the development team, the City of Oviedo will unveil its redevelopment project: a 3.7-acre public park with a walking and jogging trail. The loop trail will be part of a larger trail system interconnecting through the City and the Cross-Seminole trail, with the latter running throughout the county.

The walking and jogging path surrounds a pond with a dual purpose: to serve as an added feature to this peaceful retreat and part of an enhanced stormwater management system that will allow business owners to convey drainage from their properties via an underground stormwater management system. Along the park perimeter, historical displays will tell the story of the nearly century-and-a-half-old City’s past.

SCS helped the City navigate regulatory issues associated with redeveloping environmentally impacted land, ensuring safe and environmentally sound practices, and maximizing financial reimbursement through the Florida Brownfields Program.

In the 1940s, the site operated as a farm but lay idle and overgrown with vegetation decades after. When SCS came in to complete the environmental assessment, the team confirmed that years of pesticide application did leave arsenic behind in the soil.

“It appears that the pesticides were used appropriately, but with the change in land use and to meet the state’s environmental criteria, we need to address the residuals to redevelop the property as a park. It would otherwise remain as unusable land without this cleanup,” says Kirk A. Blevins, SCS senior project manager.

SCS completed site assessment activities according to Chapter 62-780 FAC, which includes additional testing to delineate the extent of arsenic-impacted soil further and evaluate groundwater conditions. Assessment activities indicated that while not impacting groundwater, the soil contained arsenic above acceptable regulatory levels. In its next step, the team designed a remedial action plan with multiple considerations for success.

“Given that the site would include both a stormwater management pond and a public park, we recommended that rather than cap the soil to reduce potential exposure, the City meet the strictest cleanup criteria. This option is the most protective of human health and the environment,” Blevins says.

The plan included removing approximately 47,000 cubic yards of arsenic-impacted soil, then placement of clean import fill for areas open to the public. Blevins and his team proposed excavating to the property boundary, and they provided technical guidance to the City contractor on how to efficiently and safely execute this undertaking. “It was important to excavate to the property boundary to assure removal of the impacted material so that the City would receive unconditional closure approval from the regulatory agency,” explains Blevins.

Concise reporting of the work is key to securing that approval, so SCS documented the excavation of impacted soil to the appropriate depths and lateral extents, managing it appropriately onsite, and transporting it to an approved landfill for disposal.

The team worked with the City’s environmental counsel to bring the site into the Florida Brownfields Program and prepared its voluntary cleanup tax credit (VCTC) applications for submission to the Florida Department of Environmental Protection (FDEP). All expenses and payment, confirming the expenditures “integral to rehabilitation,” are documented. With this validation, the City of Oviedo is getting back about half of its $1,432,000 related investment. It will receive another 25% bonus once FDEP issues a letter stating that no further action is required.

Documentation and communication with the state regulators is an ongoing process requiring a detailed review of contractor proposals, invoices, pay applications, proof of payment, and a summary of progress each year over the project’s life. “In particular, a line-item review of invoices can sometimes establish additional actions that are critical to remediation that otherwise might have been overlooked and not captured. This process is vital to maximize reimbursement,” Blevins explains.

Cost, as always, is a client priority. So, SCS and the remedial team focused on minimizing offsite disposal of the impacted soil, proposing over-excavating the pond, using the unimpacted soil as the onsite fill, and placing a portion of the impacted soil at the pond’s bottom.

“This was possible because testing indicated that the impacted soil would not leach arsenic into the pond water at a rate that would adversely affect water quality. We confirm that arsenic concentrations are below the strictest regulatory level before any soil from over-excavating the pond can be of beneficial reuse onsite. Safety of people and environmental protection always comes first,” Blevins says.

The ultimate outcome: Oviedo has a regional stormwater pond suited for potential commercial operations to use for drainage, maximizing available land for economic development, as well as a recreational park for the community and visitors.

SCS’s technical expertise was crucial to successfully remediating this site, attests Bobby Wyatt, Public Works Director at City of Oviedo, Florida.

“The team easily navigated and sped up the permitting process for the arsenic removal and provided continuing assistance with monitoring during construction. The process for completing the specific remediation/permitting was unfamiliar to City staff, and SCS provided efficient and competent assistance to get us where we needed to go.

Their experience provided a sense of confidence that we were going to be able to make the park project successful,” Wyatt says.

SCS has worked on brownfields projects and voluntary remediation across the U.S. for over 45 years. We convert once nonproductive commercial and industrial properties into revenue-generators and affordable housing.

Resources:

Brownfields and Voluntary Remediation

Not too long ago, SCSer Gomathy Radhakrishna Iyer thought she’d become a mechanical engineer but decided to go down another path at her father’s coaxing, and she’s never looked back. Today she is a Civil & Environmental Engineering Ph.D. and has become deeply entrenched in the world of landfills—human-made formations that she calls “beautiful.”

Dr. Iyer’s work spans research and engineering projects in landfill gas emissions reduction, landfill design, and leachate management. She’s also keeping up with PFAS to be ready for what may lie ahead around these emerging contaminants. “What I’m most into these days is researching and helping clients select leachate treatment systems and doing landfill expansion designs. It’s so mentally rewarding when you find solutions for the client’s problems. They are happy, and you are happy,” says the SCS staff professional.

She is known by more than her work family. Gomathy is a published researcher and speaker, most recently presenting at the Global Waste Management Symposium in February 2020. Her presentation covered one of her pet topics, her Ph.D. focus: using grass clippings and biosolids as biocovers to remove methane from landfills.

Pre-COVID, she spent many of her days in the field. Lately, she spends a little more time anchored to her computer in her home office. There she typically works on a few spreadsheets at a time, maybe as part of a gas emissions report, a stability analysis, or settlement analysis. Then she shifts her focus to her design drawings. Dr. Iyer still manages to break away to put on her PPE – her hardhat, safety vest, and steel-toed boots. She happily drives off in a company truck to the landfill, lugging field parameter testing probes and a 10-pound ISCO to collect leachate samples; or do other fieldwork like locating LFG wells and pipes or other features that help her design.

In the summers, it gets scorching hot. And the winters can be bone-chilling cold, especially for a woman who spent most of her life in India, where she was born and raised. In her last years there, she studied the transport of heavy metals through groundwater. Then, it was on to the University of Texas, Arlington, where she earned her Ph.D. and became set on finding work at SCS, coming on board in 2019.

Among her earliest challenges was communication. “Sometimes I would be in a meeting or having lunch with my colleagues, and they would bring up baseball or other games or a Netflix series. They were new concepts to me, and I couldn’t relate. While I speak English, I was unacquainted with the vernacular. I was like, what is Super Bowl? I thought maybe it was something very big that people eat from,” she recalls. That does not stop a researcher.

Finding a way to become better acclimated became a project of sorts. She started spending weekend downtime in front of the TV to learn about these American pastimes. Baseball still isn’t her first love, but she’s happy to say, “In 2019, I went to my first Washington Nationals game with a big group from SCS, and I had at least some knowledge of what was going on.”

The ambitious civil engineer has pushed past another on-the-job challenge—one brought on by the impulse to know every detail she can nail down before setting to work. “Since I’m from a research background, I tend to dig to the very bottom to try and know the problem completely. Sometimes it’s a good thing. But I’ve had to be conscious of time constraints, gain an understanding of the minimum required to do the job well, and move on,” she says.

What first brought her to the United States was her husband, Ramesh Padmanabhan. He was working on a Ph.D. at the University of Texas at Dallas while she was studying in India, so the relationship truly began as a long-distance one. They got to know each other through a combination of old-world traditions and 21st Century channels. “Ours was an arranged marriage. Our parents introduced us, and for the first year, we met up and talked on SKYPE,” Dr. Iyer recollects. He’s a molecular and cell biologist and sometimes her consultant too.

“In my job, I need to know the biology and chemistry of microbes as they are responsible for breaking down waste, and he is my encyclopedia. I don’t have to Google as much when he’s around.” She adds: “I can’t complete my story without talking about my brother who has given me unconditional support and career advising through my life. These two men are pillars of my life.”

As a woman civil engineer who’s all about waste, she’s in the minority, but she doesn’t feel as if she is because women are moving into waste engineering. She’s one of four women on an eight-person team, who she says is “like my family. And my supervisor is a great supporter of women in STEM (science technology, engineering, and math).”

She hears from many newly degreed civil engineers, including “young ladies” with questions about waste management. They read blogs about her work that originated on SCS’s website and are on social media. “These graduates want to take their career to the next level, and they have a lot of questions about how to start solving waste issues,” she says. She tells them that solid waste management is one of the best and most stable industries they can choose and that the pandemic has driven that point home. “We are reminded through COVID that waste management is an essential business, and there will always be jobs to support it,” she says.

What Dr. Iyer loves most about her job is what she and her team imagine and draft in drawings, keeps developing, and in time, is built. “It’s like giving birth to a baby. Very exciting,” she says. Her groundwater contamination remediation work got her interested in PFAS, even before she finished her studies. “I had a lab mate in school who did PFAS research. That got me curious about these emerging contaminants. I’ve stayed vigilant to keep up with what’s happening with regulations and treatment options under research. If regulations now under consideration are implemented, our clients will have to start thinking more proactively about addressing PFAS. So, we need to learn more on a holistic level about what these contaminants can do and the best way to treat them.”

She tells the story of how her venture into civil engineering started with her father. “He wanted to be a civil engineer himself but was the eighth son, so his parents couldn’t afford tuition, and in India, you don’t go to college once you are grown with a family,” she explains. He wanted his daughter, already drawn to engineering, to pursue what had been his dream and said he thought it would suit her better than the direction she was leaning. “Had I studied mechanical engineering as I’d been thinking of doing, I would not have come into waste.” She is happy with where she’s landed.

“When you work all day and still are not tired –you still enjoy it and are happy to contribute to something good—that’s how you know it’s the right fit.”

Somshekhar (Som) Kundral is SCS Engineer’s most recent go-getter to receive the honor of a Waste360 40 Under 40 Award. Described by his supervisor, SCS Vice President Bob Speed, as ‘humble, hungry, and smart,“ Kundral has spent no time in the slow lane.

He joined SCS as a young engineer in 2010, and quickly worked his way up, reaching a senior management position in a few years.

He now oversees multiple remediation projects, from small to multimillion-dollar jobs, taking ownership of environmental aspects of redevelopment, from remediating groundwater contamination to addressing landfill gas problems as challenges. He has come up with unique and far-reaching solutions through collaboration with his team to help clients achieve their business goals.

But before telling the story of Kundral, the senior-level engineer and project manager, let’s start with an earlier chapter.

“It’s an interesting and kind of odd story,” he recalls. “A friend asked me to drive him to a job interview as he did not have transportation. The HR person, for some reason, asked both of us to interview [having heard I was an engineer too].

“I was dumbfounded and a little nervous as I was not prepared. I had to download my resume from my yahoo ID quickly… I thought, what have I got to lose? It’s a good engineering job with a large real estate company.”

He got the job and continues to seize practically every opportunity before him, growing from each one. Today at SCS, Kundral oversees several redevelopment projects, including a 500-acre landfill conversion to a large business park, which received the American Council of Engineering-Florida and the Environmental Business Journal awards.

“The landfill had a lot of environmental and geotechnical issues, with the largest ones around groundwater contamination and stormwater management. They are typical redevelopment challenges we need to overcome, and in this case, they were on a larger scale,” he says.

As the intricate strategy evolved, Kundral, working with his project advisor, Senior Vice President Eddy Smith, called many multidiscipline group huddles. Kundral has assessed, reassessed, stopped, and restarted. And he has brought in more engineers to pump up the team’s expertise and take this project to the next level.

“We are now halfway through. And I tell you, I don’t think I should have gray hair yet, but I have some now. Still, I feel so relieved because we have the formula to make this work. “We did it by integrating the groundwater and stormwater management systems,” he says.

The integration resolves two big issues: It, of course, addresses groundwater contamination. But Kundral and the team also want to maximize areas for redevelopment, and the design supports this goal as it eliminates the need for stormwater ponds.

To him, the job is as much about open communication and teamwork as technical talent.

“At the end of the day, no matter what we do, we deal with people. I believe in staying in front of our clients, explaining what to expect when, and I continually engage with staff who support me.” With this business park conversion, as they dove deeper, they saw more intricacies. “It was important to help our client see we were not simply trying to catch up; for them to understand we had to give more time and attention to do the job as best as it can be done.”

From age 28, when he came to SCS, Kundral was keenly aware that there was potential to do plenty and wanted to take on more. “I’m just curious to see what I can get into,” he says. He began with smaller projects, each with one or two focuses. Little by little, he could connect more dots. “I could start to see the big picture and wanted to know more about how to pull the whole project together,” he says.

While he mostly oversees redevelopment projects, he has also supported industrial waste permitting and compliance reporting endeavors. He describes the latter projects as straightforward.

“I prefer the more involved brownfields projects; there is more to learn when overseeing the work. Each site is unique, with different challenges. And each time, what you discover and how you approach it is different.”

Doing the work he loves has come with tradeoffs, such as giving up kayaking and cutting back on trips to the beach—once his favorite pastimes. “They’re fun, but they are day- and night-long ventures. By the time I got home, Saturday was gone. And I needed to catch up on work emails at night and plan for the next week.”

He does find a few hours some weekends for another interest—photography—heading to the zoo or state parks with his wife, Anjana, who shares his passion for watching out for a good “Kodak moment” and capturing it.

Nevertheless, figuring out how to fix problems is still his greatest passion, further maturing from experience. When asked if he could be someone else for a day, who that would be, he thought for a while, then said: “I would love to be myself again but be able to watch as a third person and make note of the scope of improvements I have made over time. From that, perhaps I can learn even more.”

Kundral speaks of three people who helped shape him: his grandfather, father, and father-in-law.

“Growing up watching my grandfather’s resilience helped me learn how to manage hard situations.

From my father, I learned to view situations in ways to understand people better. This has helped shape my thoughts to improve my communication.

From my father-in-law, I learned the importance of humor and gained a sense of humor. This is a good thing for lightening up situations and reducing stress.”

Kundral will take on challenges because it’s part of getting to the end goal. And reaching that goal is what sparks him. He goes back to the 500-acre Florida brownfield to illustrate. “This property is being converted to a business park with great companies operating there, like Home Depot and Boeing. So, our client is creating a legacy. The project creates jobs. It brings in taxes. It improves environmental conditions. We are part of it, and that excites me.”

Kundral is in good company. These other SCS Young Professionals are past 40 Under 40 Award recipients. Like Kundral, they work diligently, solving an array of complicated solid waste challenges. SCS Engineers is very proud of our YP’s award-winning accomplishments for their clients and their contributions to their communities’ health and welfare.

Steve Linehan is a Senior Project Manager who oversees solid waste and environmental services projects from SCS’s Oklahoma City and Wichita offices. Linehan has a broad range of expertise, including solid and hazardous waste regulations, landfill design, stormwater modeling design, and remedial action plans. He holds professional engineering licenses in Kansas, Missouri, Nebraska, and Oklahoma.

Srividhya (Vidhya) Viswanathan, Vice President, is recognized for her innovative engineering plans and designs of traditional solid waste and renewable energy programs. Viswanathan, Southwest Director of Engineering, continues consolidating and integrating engineering operations to provide more streamlined and efficient services. She leads solid waste engineering operations in California, Arizona, Nevada, Utah, and New Mexico.

Solavann (Sol) Sim, a Project Director and OM&M Western Regional Manager for SCS Field Services, has expertise in all facets of landfill operations, including landfill gas and liquids management. His teams keep landfills safer and running within compliance. He is a licensed professional engineer in Alaska, Arizona, California, Colorado, Hawaii, Montana, New Mexico, Nevada, Oregon, and Utah.

David P. Hostetter, Business Manager for SCS RMC® (Remote Monitoring and Controls), works in environmental engineering and technology. He serves clients by leveraging technology to reduce business and industry environmental impacts. His environmental solutions reduce potential greenhouse gas emissions and lower environmental risk from landfills, thus protecting workers and local communities.

What is your title and responsibilities at SCS Engineers?

My title at SCS Engineers is “Project Professional.” In the Southeast region, we have something called “Assistant Project Managers,” which is not an official title. However, as the name suggests, the position entails helping the project manager run the project. My responsibilities include:

What attracted you to join SCS?

What attracted me initially to SCS was working in Environmental Services. I have been with SCS for over three years now and have expanded into sustainable materials management (SMM), which is interesting and good for communities and the environment. I’m also eager to build a more comprehensive knowledge of using what was once waste to renewable energy sources and clean-burning fuel. Solid waste management and landfills are fascinating, more than I ever imagined. SMM, renewable energy, remediation, and landfill operations are interconnected and essential for keeping people and communities safe and thriving.

What is your favorite part of working at SCS?

The people at SCS! We hire humble, hungry, and smart people. The knowledge pool is incredible, and everyone is always willing to help, no matter what part of the country you’re working. People are just a phone call away.

What do you feel is your greatest achievement or contribution to date?

I am working on a 500-acre landfill redevelopment project divided into four quadrants. Our client completed construction on one quadrant with nine buildings. We’ve received closure for eight of the nine buildings and anticipate closure for the remaining building soon. I take pride in supporting them to accomplish the closure and earn the environmental approvals safer and faster because of my combined team’s expertise and experience.

What is challenging for you as a YP?

Learning to manage my time was the greatest challenge. Regularly, I would stay late to work on projects and completing my tasks. It wasn’t a sustainable balance in my life. I said yes to everything assigned instead of letting the project manager know that my plate was full. Now, by planning my day better, prioritizing, and giving project managers realistic deadlines. I found the balance that works, and I am more productive.

What has helped with your success?

The support of management and our team at SCS has made me successful. If I have an issue with a project or unsure of the direction I need to take, I know I can rely on my team to help. There have been times when colleagues have dropped what they are doing to help me finish a project on time and within budget.

Do you have a favorite aspect of SCS’s Young Professionals Program, and describe your role as Chair?

My favorite aspect of the YP program is the mentorship program that the committee relaunched in 2020. It is such an incredible opportunity as a YP to be guided by an experienced professional. They have stood where we are today, and getting to learn from their experience is invaluable; our YPs take advantage of it.

I enjoy my role as the Chair of the YP program; I spend my energies organizing by:

What are your favorite hobbies outside of SCS?

I am a bit of a nerd, so my friends and I play Dungeons and Dragons every week. I also like DIY projects with arts and crafts – I made wall décor out of cardboard when I moved into my house!

What advice do you have for others getting into STEM fields?

When I was younger, I was advised not to go into the science, technology, engineering, and mathematics fields by my career advisors and teachers because they did not think I would be successful. In fact, because of their advice, I tried out classes in the non-STEM field like history, commerce, geography, and I did not enjoy them. I was still intrigued by the STEM field, so I listened to my gut and look where I am today! STEM is not biased. My advice would be not to let anyone tell you that STEM is not for you. If you want to study science, technology, engineering, and mathematics, just do it!

Look, I get it. If a regulator walks in the front door, send your maintenance folks out the back door with a bucket of paint. We want to make the system look shiny and as new as we can get so that the regulator might cut us some slack. However, the issue is what happens when we don’t remove the lipstick, so to speak, and clean up the dirt (in this case, corrosion) underneath. Imagine what a celebrity would look like if they never washed off the makeup that they applied each day. Now take a look around your system. Do any of your pipes or valves, or even vessels, look like …

Keeping reading Lipstick on a Pig, Bill Lape’s latest article in the Epic Fail section of the RETA Breeze, to meet IIAR6 requirements before the regulator arrives.

SCS Engineers, a top-tier ENR environmental consulting and construction firm, welcomes Professional Engineer Mary Kennamer to its environmental services team in Raleigh, N.C. As a Senior Project Professional, Mary is responsible for designing and engineering solutions to help landfills, manufacturers, and businesses comply with federal and state environmental regulations.

As a chemical engineer, Mary’s background and degree are useful to help North Carolina landfill owners prepare to meet more stringent federal and local air regulations. She will advise on air compliance issues, air permitting, compliance reporting, and consulting for landfills and manufacturing.

“Mary’s previous consulting experience and work with the US EPA is a tremendous asset and value for our landfill and manufacturing clients,” states Kenton Yang, the Raleigh office’s project director. “We’re excited to add another bright star to the Raleigh office.”

In order to permit new or expanding plants and facilities, there are complex environmental policies to meet. As an environmental and chemical engineer, Mary researches, plans, and completes the technical work for air permitting and compliance, SPCC, and due diligence that keeps owners in compliance and projects moving forward.

About SCS Engineers

SCS Engineers’ environmental solutions and technology directly result from our experience and dedication to solid waste management and other industries responsible for safeguarding the environment. For more information about SCS, please visit our website at www.scsengineers.com/, contact , follow us on your preferred social media, or watch our 50th Anniversary video.

SCS Engineers – Raleigh specializes in permitting and meeting comprehensive clean air, water, and soil goals and provides a range of services such as PFAS treatment, solid waste master planning, landfill technology, risk management, groundwater monitoring, pre-closure and landfill closures, and Brownfields remediation.

We all enjoy a success story, especially when it comes to reducing contamination in recyclable materials. Congratulations to the city and citizens for their Clean/Green campaign with its many benefits. Bill Bensing, Director of Public Services in Kirkwood, takes us through his journey in this timely APWA Reporter article.

Additional Resources:

As it does nationwide, Florida’s aspirational 75% recycling goal presents unique challenges and opportunities. Specifically, Florida municipal policymakers and professional staff are wrestling with contamination and changing global commodity markets that affect the financial viability of their recycling programs…

The Wisconsin Department of Natural Resources – WDNR is performing a waste sort to determine what’s in the trash going into Wisconsin’s landfills. During the waste audit, the team will collect at least 200 samples of waste from 12 waste disposal sites across the state for eight weeks. It’s a dirty …

Cities have begun to “right-size” their recycling systems by evaluating the usage of community recycling containers and reducing/redistributing containers to maximize the quantity of recyclables each site receives. Communities are evaluating curbside recycling programs to increase efficiency, and decreasing contamination is a priority…

Not long ago, a Utah food manufacturer turned to SCS with a persistent problem: high concentrations of fats, oils, and grease (FOG) in its wastewater— high enough to clog the city’s sewer line, knock it out of compliance, and cost it a steep surcharge year after year. As the plant worked toward a solution, its customers’ demand was growing; it reached a point where it had to expand to keep up, and that’s when the quandary came to a head. The meat processor couldn’t get a permit for expansion until the FOG was in check.

Within 18 months, SCS Project Director Mark Pearson and his team of liquid management gurus had their client within acceptable discharge limits for the first time in years. Actually, the plant’s doing a lot better than meeting the city’s requirements. Its FOG concentrations, which had spiked to thousands of mg/L, are consistently down below the established discharge limit of 200 mg/L.

The scenario Pearson walked into is that the wastewater generation and pollutant loading were highly variable as flows fluctuated. Due to hydraulic limitations, the treatment system couldn’t keep up with volumes during peak flows. As a result, the influent (untreated wastewater) was discharged from the plant to the sewer to the municipal wastewater treatment plant. And because the system was overtaxed, it did not sufficiently break down the FOG, which exacerbated the problem, wreaking havoc with the city’s collection pipes.

After completing the initial assessment, Pearson’s team developed a multifaceted approach to debottleneck the system’s hydraulics and make other improvements to increase FOG removal efficiency.

Pearson; Dean Free, senior project manager; and Nathan Hamm, program lead for wastewater and liquids management, came up with a design that achieves two main goals: It eliminates uncontrolled discharge from the plant; it greatly reduces concentrations of FOG—cutting the contaminant load to the city. Not only is the client within discharge limits, but it’s also pushed through its most immediate barrier to expansion permit approval. And it’s improved its relationship with the city.

The solution is a complex one involving chemistry, mechanical engineering, and electrical engineering. But to pare a lot of fine details down to the nitty-gritty, Pearson says:

“We put in screens that remove solids in the wastewater. We constructed a 60,000-gallon tank to equalize the flow coming to the plant. We adjusted pH to help optimize the wastewater treatment chemicals’ effectiveness. We separated the influent tank from the effluent (treated water) pipes to solve a problem where the influent would overflow into the effluent through a perforated wall. The new piping setup makes overflow impossible. And to further fortify the system, we installed a lift station to capture previously untreated wastewater.”

As a bonus, the team installed a tank that the separated FOG residual is pumped to, then hauled to a compost facility for beneficial use.

Besides adding these system enhancements, the SCS team took capabilities further with a process control and instrumentation component. The technology monitors flow rates, temperatures, tank levels, and other conditions. It processes the data and automatically makes adjustments to achieve treatment goals, avoid production downtime, and enable operators to respond proactively should they see a red flag.

Comparing the old to the new way of monitoring and analyzing, Pearson says, “What our client had before was rudimentary information. And while they could monitor conditions, they had to walk around the plant. All of the operational data can be viewed on a screen now from one location. They have more data at their fingertips and more capability to make adjustments to avoid discharge exceedances.”

The wastewater treatment system upgrade was done as a design-build to speed the timeframe while also increasing efficiency. “We could immediately start rather than put it out to bid. We could do construction as we designed. And there was one entity and one point of responsibility. So what’s cool is we leverage both SCS engineering and construction capabilities to solve problems,” Hamm says.

He and his colleagues have the know-how to pivot on a dime if they have to, and there were a couple of times it was necessary, including when the client brought new management on board midway through the installation process. The new team preferred different instrumentation and had a specific scheme in mind.

“We were in the process of installing the original instruments. But we were able to incorporate their equipment preference midstream. We had to figure out how to get new instruments installed and ensure they were perfectly integrated with the computer control system that takes readings from the instruments. It was what they wanted, so we saw that they got it,” Pearson says.

While he and his co-workers’ jobs as project design and build engineers are done, they have not faded from the picture. They provide ongoing technical support when the client needs assistance with troubleshooting. The automated control system has helped.

“This is a robust and complex mechanical treatment system. If by chance, something was wrong, our client can transmit data that comes out of the process controller so we can work remotely to determine if process changes are needed. If they are, we can often make those changes from offsite, and quickly,” Hamm says.

But the SCS team also plans so that its client is equipped to ensure its success moving forward. They provide operator training. And they developed a standard operating and maintenance procedures manual and a checklist to track data and activities transferred from shift to shift, providing operators a standard and seamless way to communicate.

The busy Utah plant is on a good trajectory, with solid footing.

Says Pearson: “Before, they could not expand the plant or even continue their operations much longer if they did not get the FOG under control. Now they can operate continuously, discharge to the city, and they have potential to expand their plant because they are showing the regulators they can stay within their permit limits.”

Additional Resources and Case Studies:

According to the Occupational Safety and Health Administration (OSHA), National Institute for Occupational Safety and Health (NIOSH), and the World Health Organization (WHO), noise is a serious health concern in the 21st century. Although Personal Protective Equipment (PPE) is seemingly the least expensive and simplest control for noise, PPE is also the least effective. It relies on personnel to utilize the correct PPE at the appropriate times.

Approximately 22 million workers are exposed to hazardous noise levels each year in the United States, and over 10 million US workers have diagnosed Noise-Induced Hearing Loss (NIHL). (1) Industries with high numbers of workers exposed to loud sounds include construction, agriculture, mining, manufacturing, utilities, transportation, and the military. Excessive noise can lead to a range of health problems for all citizens, but a growing number of non-industrial workers, including restaurant and school employees, are experiencing this irreversible occupational hazard.

Noise in U.S. industry is an extremely difficult problem to monitor, acknowledges Craig Moulton, a senior industrial hygienist for OSHA. “Still,” he says, “OSHA does require that any employer with workers overexposed to noise provide protection for those employees against the harmful effects of noise. Additionally, employers must implement a continuing, effective hearing conservation program as outlined in OSHA’s Noise Standard.”

Sounding Out Realistic and Effective Solutions

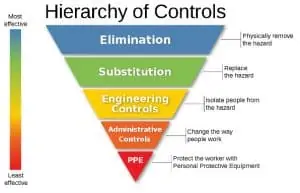

SCS Engineers Industrial Hygienists utilize the hierarchy of controls when developing solutions that involve elimination, substitution, and engineering controls as the first steps to controlling excessive noise. Only when a solution cannot be identified or implemented from these controls do we look to administrative controls and PPE.

“When we design our investigations and remediation plans to address specific noise issues, we are also sensitive to the costs associated with expensive analytical testing,” states Jed Douglas, Industrial Hygiene National Expert. We find cost-effective and lasting solutions by:

SCS has completed numerous noise investigations and sampling for various facilities, such as schools, offices, warehouses, industrial and commercial buildings. SCS’s Industrial Hygienists help building owners, facility engineers, property managers, attorneys, insurance companies, and municipalities with investigations and remediation of the factors contributing to excessively loud noise, including area sampling and surveys of personal exposure for regulatory compliance. We can also help with hearing protection programs, medical monitoring programs, and the selection of PPE.

Additional Information

Noise pollution, also known as environmental noise or sound pollution, is the propagation of noise with ranging impacts on human or animal life activity. Machines, transport, and propagation systems mainly cause outdoor noise sources worldwide, including highways; construction activities; urban congestion; power generation; public transportation, recreational vehicles, home power tools, yard maintenance, and air cooling equipment.

Common sources contributing to harmful industrial loud noise:

Health effects from loud noise include: