Graphyte is a carbon removal and sequestration firm backed by Bill Gates’s Breakthrough Energy Ventures. Operations began at its Arkansas-based plant in February 2024. What is notable about this carbon sequestration solution is its price, which is considerably lower and can work faster than other sequestration solutions.

Carbon removal is essential to fighting climate change. Billions of tons of carbon dioxide need to be removed from the atmosphere annually by 2050 to achieve climate change goals, but unfortunately, the world is not on track to make the goal. In the spirit of doing more with less, SCS Engineers supports Graphyte’s new solution to capture more carbon. As a leading environmental engineering firm in the Americas, we are experts in designing and implementing safe and long-lasting solutions that reduce, reuse, or store waste.

How Graphyte’s Carbon Casting Works

By-products of the timber and agriculture industries, otherwise burned or left to decompose, are collected. These by-products are considered biomass, dried to stop decomposition, and then condensed into dense blocks. The blocks wrapped with an impermeable polymer sheet make them environmentally safe and ensure that decomposition does not restart.

Then, the blocks are stored in state-of-the-art sites with sensors and tracers, enabling robust long-term monitoring. Storage sites can serve multiple purposes, such as solar farms or agricultural land, designed to last up to 1,000 years.

Sustainable Solution

Industries and businesses are moving to be as carbon-neutral or carbon-negative as possible, looking at carbon sequestration as an attractive reduction solution because it ticks so many boxes that make it sustainable. It sequesters carbon and does it for centuries while meeting environmental, social, and economic considerations that are extremely important. To be sustainable, a solution’s return on investment must be reasonable so customers can still afford the product or service.

Closing the Gap Between Plans and Results

Many industries and businesses combine sequestration with additional strategies that lower their produced carbons. For example, landfills and municipalities encourage diversion and recycling programs to lower methane and produce useful by-products from a large portion of what remains. Energy audits identify how to run facilities and processes more efficiently and may incorporate renewable energy from organic material, methane, or solar to power facilities.

Carbon removal is necessary to manage Climate Change and ultimately save the planet. Using an upstream and downstream approach, Graphyte offers a safe, affordable, and scalable way to sequester carbon dioxide as North America implements more reuse and recycling infrastructure to lower waste generation upstream.

Additional Resources for Carbon Mitigation and Sequestration

On May 26, 2024, Illinois passed legislation aimed at regulating carbon capture and storage projects at the state level. The Safety and Aid for the Environment in Carbon Capture and Sequestration Act (SAFE CCS Act) has a broad scope, bipartisan support, and support from industry, environmental advocacy groups, and other Illinois stakeholder groups.

SCS Engineers believes the SAFE CCS Act will impact schedule, cost, and scope in Illinois’s permitting, operation, and post-closure phases of Class VI projects.

Please join long-time Illinois Deep Well Practitioners Stephanie Hill, Charles Hostetler, and Kacey Garber for a look at how SCS will apply our state-level experience to help Project Developers, Owners, and Operators focus their permitting, operational, and reporting practices to navigate these complexities and minimize Class VI project risk.

Click on Additional CCS Resources:

Click to Read CCS Articles:

Geologic Media for Carbon Sequestration and Deep Well Injection Projects – Always Building UIC Knowledge

SCS Engineers provides turnkey underground injection control (UIC) services for the deep injection and permanent geologic storage of liquid waste (Class I UIC) and carbon dioxide (Class VI UIC). The ability to interpret and correlate deep well logs is fundamental to developing the geologic site characterization and subsurface modeling components of our deep well injection and carbon sequestration projects. We ultimately use the data gathered from these logs to construct geologic maps, cross sections, and static geologic models during the pre-permitting and permitting phase of these UIC projects. This allows us to explore optimal injection strategies for safe and efficient projects.

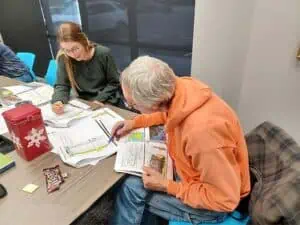

Recently, a group of scientists from the SCS Carbon Sequestration and Deep Well Injection Team gathered at our office in Wichita, Kansas, to attend a three-day course on deep well log interpretation and correlation. Dr. Ali Jaffri, the CEO of Applied Stratigraphix, a Denver, CO-based consulting and training firm, led the course. They offer a variety of training workshops and field courses focused on subsurface geologic interpretation, primarily for oil and gas industry geologists.

The course covered topics including:

The course devoted considerable time towards getting hands-on experience working together on interpreting and correlating well logs, including logs from our current UIC project areas, and discussing how we can apply the concepts we learned in other regions. We highly recommend this unique training for geologists in carbon sequestration.

We never stop learning, innovating, and sharing.

SCS is incorporating the content from this course and other published resources into developing updated and refined standard operating procedures for producing geologic deliverables for our deep well injection and carbon sequestration clients. As our subsurface geology team continues to expand as we meet the needs of this rapidly growing market, we are committed to operating as a high-performance team to provide quality geologic deliverables to our clients on every project.

Kacey Garber arranged the training event, contact her on LinkedIn for more information.

Learn more about Carbon Sequestration and UIC here.

Since the 1980s, the USEPA and state regulatory agencies have made great strides to regulate wells and have a robust list of requirements that industrial, municipal, commercial, and manufacturing applicants must adhere to for installing and operating a deep injection well.

Despite the regulations, many communities fear injection wells, and who can blame them? Cutting through the misinformation and online “studies” makes understanding the facts and science difficult. The myriad of groundwater concerns making headlines can become overwhelming. This video, by our team of environmental and injection well experts, takes you through the critical elements and regulations when considering injection wells. And how they help create a safe well site acceptable to regulatory authorities, communities, and industry.

Ms. Bansal reviews the significance of the following factors for a USEPA “safe” deep injection well:

Number one is proactive engagement; it is critical to talk to all stakeholders, including community organizations, the public, and local environmental advocacy groups, about the well installation plan covering the ‘how and where.’ Early involvement in the process leads to a better understanding of the benefits and factors you, as an applicant and local business, are implementing for the public. ~ Kokil Bansal

Additional Resources

Commercial Carbon Capture and Sequestration in the US

The US is home to the largest number of commercial carbon capture and sequestration (CCS) projects worldwide, with approximately 50 new projects announced in 2021, according to the Global CCS Institute. SCS contributes expertise to several ongoing and groundbreaking carbon dioxide geologic sequestration projects. These projects have highly advanced permitting and monitoring requirements.

Research published in a report by the Congressional Research Service defines three main types of sites ideal for underground CO2 injection and sequestration: depleted oil and gas reservoirs, deep saline reservoirs, and un-mineable coal seams. In each case, CO2 in a supercritical state is injected into a porous rock formation below ground that holds, or previously held, fluids. When injected at depths greater than half a mile, the pressure keeps the injected CO2 entrained within the formation fluids, where the CO2 will subsequently dissolve.

Selecting a Site

The target geological injection interval must have an overlying impermeable caprock, such as shale, so the injected CO2 doesn’t migrate into overlying formations, most specifically, the underground source of drinking water. Fortunately for geoscientists and engineers, most of the technology used to assess the subsurface was initially developed by the petroleum industry, including a variety of geophysical techniques, including seismic reflection.

Using Seismic Reflection Technology

At SCS, our team uses the same seismic reflection technology and methodology developed by the oil and gas industry to evaluate the subsurface. Seismic reflection is a powerful tool when used properly and allows us to interpret the depositional background of the system and identify permeable and impermeable units. Seismic reflection involves generating seismic waves (the source) and measuring the two-way travel time taken for the waves to travel from the source, reflect off an interface, and be detected by an array of receivers at the surface. The reflected signal is based on the density-velocity contrast at the interface. Depending upon the type of source and receivers, seismic reflection, once recorded and processed, provides 2 or 3-D imagery of stratigraphic boundaries and geologic structure –all at depths ranging from hundreds of meters to several kilometers.

In-house experts enable SCS to utilize this amazing tool, which enables teams across the organization to see where the best areas for injection are by interpreting seismic stratigraphy. We can determine the continuity of a layer and the presence (or absence) of faults and fractures. The data can also help us determine the type of fault and whether it is a sealing or a transmissive fault. For example, a fault-bound anticline (when the rocks push up from stress changes) may provide a stratigraphic trap for hydrocarbon and can potentially store CO2.

We use seismic reflection in the initial phases of a project to determine the depths and lateral extent of known lithology. We employ previously mapped lithologic units to correlate the “images” created in seismic profiles to existing formations and, in doing so, perform a “check” on the seismic interpretation.

Long Term Benefits

Seismic reflection provides significant input when choosing a reservoir or siting a well; however, its use doesn’t end with an initial site assessment. The technology provides robust methods for monitoring the CO2 plume and interpreting changes to the subsurface during and post-injection. SCS has two Class VI injection projects where seismic reflection data was employed to identify the target injection zones and seals. The next step will be using the data to look at the subsurface relative to the injection well using downhole sensors, a process known as vertical seismic profiling.

The requirements surrounding the Class VI permitting process are complicated, but SCS has in-house experts with the skills to employ seismic reflection. Teams continue to hone their skills in this area as clients value and trust partners who can demonstrate a thorough understanding of permitting carbon sequestration projects.

The Class VI permit application typically takes 18 to 24 months to receive approval. The process is laborious and expensive. Demonstrating expertise here is critical as SCS Engineers continues to play an integral role in advancing supercritical CO2 projects throughout North America.

Additional Resources and Educational Materials:

Did you miss the 2022 Annual GWPC & UIC Conference in Salt Lake City? We welcome you to view SCS Engineers’ presentation by Kacey Garber entitled “Sensitivity of Aquifer Chemistry to Changes in Carbon Dioxide Partial Pressure: Implications for Design of Groundwater Monitoring Protocols,” where Kacey discusses permitting requirements for groundwater monitoring for carbon sequestration and storage sites.

In her technical presentation, Kacey Garber of SCS Engineers discusses the great care taken in the design and operation of the injection of carbon compounds to ensure that the sequestration is effective and permanent. Each injection site also has permitting requirements for groundwater monitoring in any overlying aquifer as a protective measure. Because the injection and sequestration periods are long, CSS solutions need a cost-effective groundwater monitoring program with a robust sensitivity to detect any leakage. By establishing a groundwater monitoring protocol specific to the site, sensitive to changes in the partial pressure of carbon dioxide, and relatively insensitive to natural variability and hydrochemical facies changes, implementing optimal and cost-effective groundwater protection is possible. Using a case study, Kacey tells us how her team did this in detail.

Kacey Garber is an experienced groundwater project manager for active and closed landfills, including routine groundwater monitoring and statistical analyses; reports and permit applications; designing sampling and analysis plans; special groundwater studies; and conducting groundwater well construction planning and design.