Learn about SCS Engineers Air Emissions Services

Our latest SCS Technical Bulletin summarizes the EPA federal mandatory greenhouse gas (GHG) reporting program (GHGRP) into two pages of the most vital information. The new reporting requirements for Subparts HH and A discussed in our bulletin are effective January 1, 2017.

Remaining updates will be phased in from 2017 to 2019. These updates include, but are not limited to, revisions to the reporting regulation for all reporters including Subpart A Administrative Requirements, Subpart C Stationary Combustion Sources, and Subpart HH Municipal Solid Waste Landfills the three most common reporting sectors for MSW landfills. SCS Engineers will continue to post timely information, resources, and presentations to keep you well informed.

Use our resources for guidance or to answer questions.

Share, read, or print the Technical Bulletin

Greenhouse Gas Service Information

SCS Engineers provides a free guide to the most common environmental reports due at the federal and state levels. Each guide includes an overview of the reporting due along with the date each state requires submission.

When SCS says free, we mean it. No need to submit your company name, no endless email trail will follow; these are free guides to download and share with others from the compliance experts – SCS Engineers.

Click to download or share each state guide:

If your state is not listed, contact the nearest SCS office to speak with a compliance professional in your area and in your business sector; SCS is nationwide.

If you have questions or need help sorting out details such as which reports apply to your business or step-by-step support on how to prepare your reports in the states listed above, contact our regional professionals.

Learn more about Ann

Ann O’Brien 1-773-775-6362

Learn more about Cheryl

Cheryl Moran 1-608-216-7325

Article in Waste360: explains who’s impacted and how to begin managing the costs.

SCS Technical Bulletin: a digest of hundreds of EPA regulatory policy into the information and timelines to act on now.

Article: strategic financial planning to support infrastructure costs.

Call our compliance specialists – find the office nearest you or email us at

…and as waste settles, it can have an effect on equipment,” according to Pat Sullivan of SCS Engineers in this ClimateWire article. As the U.S. EPA focuses on pushing landfill owners into cutting down on methane emissions some worry that a combination of tightening regulations and poor cost analysis might put some smaller landfills out of business.

LANDFILL EMISSIONS: Going to the dump? You might make electricity

Kavya Balaraman, E&E reporter

Reprinted from ClimateWire with permission from E&E Publishing, LLC. Copyright 2016.

Read the NSPS – EG Technical Bulletin

On July 11, 2016, multiple organizations representing the full value chain of cellulosic waste feedstock conversion to transportation fuel sent a letter to Gina McCarthy, Administrator of the U.S. Environmental Protection Agency (EPA). The letter supporting the Renewable Fuel Standard Program: Standards for 2017 and Biomass-Based Diesel Volume for 2018 (Proposed Rule) noted that additional information and factors need to be considered.

Read or share a copy of the letter here, contact SCS Engineers, or one of the organizations below:

SCS Engineers has published two Technical Bulletins summarizing the O&G NSPS final rule and outlining the new LDAR requirements. The two Bulletins explain the modification of how oil and gas sources will be permitted under the Clean Air Act and the new requirements to reduce methane leaks from new oil and gas facilities consistent with the EPA’s New Source Performance Standards.

Reference the U.S. Environmental Protection Agency (EPA) new source performance standards for Crude Oil and Natural Gas Production, Transmission and Distribution (O&G NSPS), which includes amendments to 40 CFR Part 60, Subpart OOOO and a new Subpart OOOOa. Subpart OOOOa will apply to facilities constructed, modified or reconstructed after September 18, 2015.

Click to read or share the Technical Bulletins:

https://www.epa.gov/controlling-air-pollution-oil-and-natural-gas-industry

Pat Sullivan, REPA, CPP, BCES

(916) 361-1297

Question: I have a small oxidation event at my landfill and am continually testing for carbon monoxide (CO) in the surrounding landfill gas (LFG) extraction wells. Using colorimetric tubes, I am monitoring the readings which range from 5-10 parts per million (ppm). Is there an accepted standard for background carbon monoxide in LFG? Moreover, how much inaccuracy is expected using the colorimetric tube testing?

Answer: Carbon monoxide (CO) can be found in small quantities even when there is no landfill fire. If your concern is landfill fire, most reputable resources state that a landfill fire generates readings of at least 100 ppm CO and more typically in the 500-1000 ppm range with 1000 ppm a reliable indicator that a landfill fire event may be present.

CO readings on colorimetric tubes are inherently less accurate and tend to run higher than laboratory results. Colorimetric tubes do provide value as a real-time indicator versus subsequent lab results, and can be used as an index reading, calibrated by lab results later. If you’ve had a landfill fire event before, with CO levels greater than 100 ppm, the lab confirmed 5-10 ppm CO could be residual left over from the earlier event.

Although some people believe that the presence of CO at almost any level is an indicator of landfill fire, recent laboratory tests show that CO can be generated at values up to and over 1000 ppm by elevating refuse temperatures without the presence of combustion (fire). Other tests have shown that high values of CO are found in some landfills with no current landfill fire and no indication of a past landfill fire. This information supports that it is possible that Elevated Temperature (ET) Landfills can have CO levels over 1000 ppm CO without the presence of combustion or landfill fire.

In the end, CO can be an indicator of landfill fire, but not always, as described here. Low methane, high carbon dioxide, and even landfill temperatures above 131 degrees F may or may not be indicators of past or current landfill fire. Physical indicators of a landfill fire may include rapid settlement in a localized area, cracks and fissures, smoke and flame, melted landfill gas system components, and char on the inside of LFG headers and blower/flare station components such as a flame arrester. However, most of these indicators can occur at ET landfills as well without the presence of fire or combustion.

A professional landfill gas engineer is needed to assess these conditions as a whole, and make a judgment on the underlying driver, condition, and resolution.

Have a question for our SCS Professional Engineers or Field Staff? Just ask here.

Landfill and Landfill Gas Services at SCS Engineers.

An SCS Engineers Technical Bulletin will be released early in the week.

The U.S. Environmental Protection Agency issued limits on methane emissions from oil and gas wells that are more stringent than those it proposed last year. The final regulations released on Thursday, May 12, 2016, will add hundreds of millions in additional costs per year; at least 25 percent higher than the preliminary version published in August 2015.

EPA Administrator Gina McCarthy told reporters on a conference call that the mandates, applying immediately to new and modified wells, are a “critical first step in tackling methane emissions from existing oil and gas sources.”

Under the rule, companies must upgrade pumps and compressors while expanding the use of “green completion” technology meant to capture the surge of gas that can spring out of newly fracked wells. Such green completion techniques have been required for new and modified natural gas wells since 2015, but Thursday’s rule would broaden the requirement to oil wells too.

Take me to the EPA summaries. Click on the information sheets listed below:

The Solid Waste Association of North America (SWANA) Applied Research Foundation released a report concluding that: a significant amount of additional food waste processing capacity will be required to achieve national, state, provincial, and local food waste diversion goals. The report also emphasizes the need for local decision-making in selecting and implementing those food waste diversion programs.

…a significant amount of additional food waste processing capacity will be required to achieve national, state, provincial, and local food waste diversion goals. The report also emphasizes the need for local decision-making in selecting and implementing those food waste diversion programs.

The report goes on to say that interest in recovering food waste from municipal solid waste is growing to meet goals established by the U.S. Environmental Protection Agency and U.S. Department of Agriculture, but many major metropolitan areas lack the infrastructure to manage the ability to meet the established goals. Two examples were cited:

Several states, including Massachusetts and Connecticut, condition their food waste diversion requirements on the ability of generators to access adequate capacity within a certain distance.

Speaking as SWANA’s Executive Director and CEO David Biderman stated:

We believe that Americans need to rethink how food is handled before it is considered waste, to divert it into programs to feed people, and to find other productive uses for food as food. Once it becomes waste, however, municipal decision-makers, working with their processing partners, need to determine how to best manage the material.

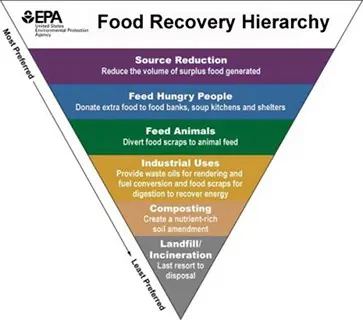

The SWANA report focuses on the effects of food recovery at the two lowest tiers of the hierarchy – composting and landfilling/incineration. The report concludes that food waste diverted from landfill operations has the potential to be processed at composting facilities. Then, going on to say that anaerobic digestion (AD) and co-digestion at wastewater treatment facilities are also likely destinations for diverted food waste.

Jeremy O’Brien, Director of the Applied Research Foundation, noted:

The food recovery hierarchy does not apply universally; an analysis of greenhouse gas impacts based on local data and conditions is needed to identify the best food scraps management options for a specific community.

The report encourages solid waste managers to perform a life cycle analysis of economic and environmental costs and benefits based on local needs, system capabilities, and data to identify the most effective ways to manage food waste at the local level.

SCS Engineers and SWANA are both long-time advocates for local decision-making in establishing programs to collect and manage municipal solid waste.

Related articles: