Learn about SCS Engineers Air Emissions Services

Hydrogen sulfide (H2S) levels are creeping up at some landfills, especially those that take C&D waste; some are seeing concentrations in the thousands to 30,000 parts per million (up from about 20 to 40 ppm ten years ago). And even at very low concentrations, H2S can be problematic.

Material Recovery Facility residuals, which typically contain significant amounts of pulverized drywall, are high in gypsum and sulfate. Once broken down, residuals become a high-surface-area material, leaching into and spreading through waste. When reacting with water and organics, it can potentially generate H2S. With a drive to divert more C&D debris, and regulations tightening around H2S, operators’ jobs get harder as they work to stave off emissions from this corrosive, flammable compound notorious for its “rotten egg” odor.

When building out their gas collection systems, controlling H2S becomes even more daunting. Sol Sim, an SCS Engineers Vice President, explains, “We see H2S concentrations jump when we expand landfill gas collection systems, often in cells that contain C&D residual screening materials. The gas was there all along but sequestered. Now it’s coming out of the ground, and the onset of issues can spike suddenly.”

When spikes come on quickly, Sim’s team implements turnkey interim treatment approaches. They start by identifying the gas collection wells with the highest contributors and act fast to get them into compliance.

SCS teams take a two-pronged approach by stepping back and thinking about the big picture while taking action. It provides a major advantage to moving too quickly.

The more data, the better. Your engineers can simulate treatment with various media to assess the impact on flare inlet concentrations. And knowing potential impact at the flare is critical; it’s the compliance point where regulators measure sulfur dioxide (SO2) emissions.

SO2 can’t be controlled through combustion, so removing H2S from waste before sending gas to the flare is essential. Sim thinks back to problems he’s investigated for clients who had SO2 sneak up on them, causing failed sulfur dioxide emissions testing.

The proactive measure of identifying problematic gas wells and treating them is key to staying in compliance. And Sim often finds clients using interim solutions as long as they can. He has seen them work well for up to five years but they don’t resolve operators’ long-term issues, which will become more challenging as our waste streams continue to change or as landfills continue to accept more and more C&D materials.

“We’re going to investigate thoroughly to pinpoint and understand the cause, but we do take immediate action in the interim. As part of the solution, we’ll develop an informed strategy to prevent issues well into the future,” he says.

For the longer haul, it takes time to get building permits. Coming up with permanent engineering designs and treatments requires a lot of troubleshooting and research. Even once engineers identify a lasting fix, it takes time to manufacture and install larger vessels and other infrastructure.

But they don’t wait for all these pieces to come together to act.

The priority is getting operators in compliance right away or taking down emissions if they are on the verge of noncompliance. As work begins, operators can breathe a little easier knowing they have time to figure out how to allocate resources and funds to implement a more permanent strategy.

“We’ve seen where data we’ve gathered while working on the immediate problem enables our clients to gain insight to make good decisions around rightsizing their infrastructure moving forward,” Sim says.

Watch and study while addressing the immediate problem.

Sim emphasizes that operators should not be surprised or act too quickly when they turn on the gas extraction system and see spikes in H2S concentrations. There is usually an initial spike from a new high H2S producing area at the onset of gas collection. He has seen operators abruptly stop extracting, which can lead to odors or other compliance issues.

“When you put in a treatment system, you can take out the initial surge in H2S to allow time for the concentrations to level out. It’s important to allow that window for initial surges to run their course to understand the problem better. Otherwise, you could over-design your system around a short-term event,” Sim advises.

He points to a real-life scenario: a site that skipped the interim step of starting with a less expensive initial solution. Once they started drawing on the gas, they realized the problem was not as substantial as originally thought, and they didn’t need a multi-million-dollar system in the end.

A balancing act.

“Imagine H2S generation as an expanding balloon; if you pop it, air rushes out fast [akin to when you first pull gas from the ground]. That concentration level scares people. But if you react by shutting off extraction points, your balloon will continue to expand and eventually create odor problems. The goal is to extract the gas and H2S at the rate it is being generated, so it’s a balancing act, where expertise and technology both play key roles,” Sim says.

Early work typically begins by identifying wells that are the highest contributors and concentrating efforts there. It’s a complex process as sites can have fifty to thousands of collection points. Having the historical data and saving the data to watch the trend makes identifying and analyzing specific wells or clusters much more efficient.

Successfully attacking those high offenders requires an understanding of flow and concentrations. After locating the problem area, Sim takes samples using Dräger tubes at strategic points throughout individual wells and headers to identify concentrations. Gas well monitoring and the corresponding flow data will tell you if you’ve taken emissions down sufficiently.

More Resources:

SCSeTools Landfill Data Monitoring and Analysis

Staying Ahead of Odor Management at Solid Waste Facilities

New Chicago office location at 40 Shuman Boulevard, Suite 216, Naperville, IL 60563

SCS Engineers continues expanding its environmental team in its Chicago, Illinois office to meet environmental engineering and consulting needs focusing on waste management and the needs of the electric utilities. Driving demands are industries and municipalities seeking to reduce their environmental footprint while providing essential services and products.

Meet the Crew!

Brett Miller is a Senior Designer with over 20 years of experience and proficiency in AutoCAD Civil 3D and Maya. Brett is capable of any production drafting and is highly skilled in understanding 3D space. This helps him support designs that fit into site-specific, real-world environments. Brett also creates 3D models and animations that illustrate the benefits of a design to our clients.

Niko Villanueva, PE, joins SCS with eight years of experience. Niko provides engineering and drafting support and is experienced in designing various landfill systems such as stormwater management, leachate and gas control, and foundation analysis. He has also prepared cost estimates and construction bid quantities for various projects and construction quality assurance services at multiple facilities.

Recently the state of Wisconsin released its updated 2020-2021 statewide waste characterization study. The study found that the broad organics category, including yard waste and diapers, accounted for about 1.3 million tons. An estimated 924,900 tons of paper, including cardboard, compostable and office paper, comprised about 21 percent of the landfills’ tonnage. That was followed by plastic at about 17 percent or 745,600 tons.

You can read the study, but why do local governments, states, and waste management businesses request these studies? Because waste and landfills are expensive to manage. Diverting waste from landfills cuts greenhouse gases and supplies materials for reuse as new products or compost – a more sustainable system.

Waste characterization information is designed for solid waste planning; however, anyone interested in the characteristics of the solid waste stream may find it useful. Studies can also target specific waste or needs such as construction and demolition waste and business waste generators. A generator means a person, specific location, or business that creates waste.

These studies help start answering questions such as:

States, jurisdictions, citizens, and businesses can use this information as a planning tool to help meet state mandates and their goals to reduce waste and achieve the benefits of sustainable practices. Kudos to Wisconsin, Iowa, and California, several of the many states moving toward more circular waste management!

Approved

The EPA issued a newly approved alternative test method (ALT-143) for compliance with the enhanced monitoring provisions in the National Emission Standards for Hazardous Air Pollutants (NESHAPs) for MSW Landfills (40 CFR 63 Subpart AAAA updated March 26, 2020). The approved alternative method instead of Method 10 allows for direct monitoring of CO at a landfill gas well using a portable gas analyzer. The NESHAP requires weekly monitoring of CO at the landfill gas well if the gas temperature is over 145F and the regulatory agency has approved no higher operating value under the NSPS/EG rules or NESHAPs. The Solid Waste Working Group (SWWG) coordinated with landfill gas meter manufacturers (QED, Elkins Earthworks) to prepare this method.

EIL approved sharing a flow chart and Excel file that can be used for monitoring/documentation purposes when using this approved alternative “field instrument method.” Don’t hesitate to get in touch with your SCS air emissions/compliance expert or contact us at for details.

EPA will post the alternative test method to the Broadly Applicable Approved Alternative Test Methods | US EPA website page. Take note that the hyperlink in EPA’s letter is out of date.

Pending Approval

The Solid Waste Working Group (SWWG) also submitted two alternative methods in lieu of Method 10 to EPA for approval using grab sample (canister, foil bag) and laboratory analysis, one with GC/FID and the other GC/TCD instrumentation. The SWWG coordinated with several national laboratories on the methods. EPA is completing its review of the two proposed methods, anticipating EPA approval before September 27, 2021, the effective date of the enhanced monitoring provisions.

Progressive energy companies are rushing to corner the growing hydrogen market, excited as they see this renewable fuel’s cost steadily drop and as they prioritize decarbonization.

As they work to stay ahead of the pack, they need to put time and thought into building out and implementing these projects. There are complex technical and regulatory considerations; safety is also priority one at every step when managing this flammable, compressed gas.

As the market takes off, there is a need for scaled development along the whole supply chain, and some developers are rising to the occasion for more control and more opportunity. Rather than only build fueling stations, they buy into vertically integrated hydrogen networks to produce, transport and distribute hydrogen. But these multifaceted projects present even more complexity— calling for a team with highly specialized, comprehensive skill sets.

SCS Engineers supports energy companies and contractors looking to diversify their hydrogen services portfolio to include building production plants, including moving the gas via pipeline or truck to offload at fueling stations, ultimately selling to consumers.

“We enter these strategic partnerships to give our clients what they are looking for: a full spectrum of competencies and services; and a proven history of working on hydrogen to deliver turnkey projects. The idea is to take the environmental burden off clients as they pursue these major undertakings,” says Nathan Eady, an SCS vice president, and project manager.

SCS makes site selection; performs environmental due diligence and remediation; feasibility analysis; design and construction of environmental controls; land use, air, and water quality permitting.

The contractors’ specializations are detailed design, engineering, and construction management–from civil to structural to mechanical and fire protection.

This team meets all environmental and regulatory design requirements and develops process safety management and risk management plans with their combined expertise. They also take on the role of community educator, explaining the unique attributes of hydrogen and easing any concerns.

“We take science and engineering and translate that for neighbors and city councils. It’s important to show communities, as well as regulators, that these facilities are designed and operated with the utmost safety,” Eady says.

Requirements vary from jurisdiction to jurisdiction. But with a national reach, SCS sails through processes and regulations by region.

“That matters to our clients; they want to get through the detailed permitting steps and launch as soon as they can to maintain their competitive edge. And when they plan to expand into other regions, they like to know they already have a vetted team in place who knows the territory and can do the work there,” he says.

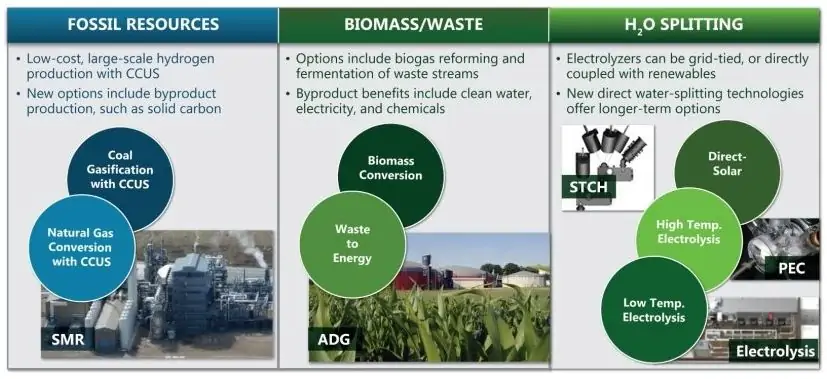

Permitting and technical considerations vary by location and production method, whether via steam methane reforming (SMR) or electrolysis.

Some operators are taken off-guard by the air quality permitting requirements associated with SMR facilities − or the stringent wildlife and water quality regulations encountered with the larger footprint photovoltaic systems requiring open space to support electrolysis. SCS has the expertise to address the issues, whether state-specific cap and trade regulations for carbon emissions or air basin specific criteria pollutants. SCS also has the unique talent of finding brownfield sites or closed landfill properties, making excellent receiver sites for electrolysis and solar facilities near existing infrastructure.

Building hydrogen projects on these idle properties can save developers significant time and money in the overall project outcome.

“We do a lot of brownfield work helping to clean and redevelop these properties. These sites have special permitting considerations, especially since they typically have a history of industrial use,” Eady says.

SCS performs Phase I Assessments to research records on previous use, and if the team finds a potential problem, they move to Phase II, which entails groundwater and soil testing.

“If we find evidence of existing contamination, we reconcile it so our clients can move forward with the development of their new facilities,” Eady says.

SCS is seeing a growing interest in building hydrogen projects on closed landfills. As brownfields, they have value for their open space and often have some existing infrastructure, offsetting the cost of building new.

“We have done permitting and design work on several closed landfills, sometimes adding solar systems. Hydrogen projects leveraging electrolysis require a tremendous amount of electricity, and when we can bypass the grid enabling clients to make their own electricity, it’s a major plus,” Eady says.

Lately, large energy companies are pivoting from conventional oil and gas to hydrogen, and some smaller, young companies are also joining the clean renewables movement.

SCS has gotten interest from startups looking to obtain government grants and subsidies. Some of these firms need more process engineering support to ensure their new technology can operate at a cost and environmental efficacy equivalent to larger operations.

“We use our knowledge gained working with major conventional energy companies to support these new hydrogen firms in executing successful launches. All in all, a positive trend.”

Together, SCS and its partners play an integral role in helping to see hydrogen continue to climb the energy sector ranks, maintaining an excellent record of accomplishment supporting the planning-design-build of clean-energy plants.

Additional Resources

Landfill data collection and analysis are more tactical than ever, and landfill technology provides methods to manage and use the data to create efficiencies. With the implementation of the NESHAP, NSPS/EG requirements, Landfill Operators will monitor more often and maintain more records. Data collection mechanisms will likely broaden soon to include drone and satellite data collection as acceptable for agency requirements.

Our September 23, 2021, SCS’s Client Webinar focuses on landfill gas maintenance and how Operators find efficiencies by monitoring and collecting LFG data. Using SCS eTools, the webinar includes common scenarios at landfills and answers several questions, including:

Demonstrations include:

The International Awards Committee and Solid Waste Association of North America (SWANA) Board of Directors unanimously voted to honor Tom Conrad, the “C” in SCS, with the Robert L. Lawrence Distinguished Service Award at WASTECON 2021 in November. The Lawrence award is the highest accolade SWANA bestows on a member of the waste management industry, reserved for those making meaningful and lasting contributions.

“I’m honored and humbled to be selected for the Robert L. Lawrence Award. I thank you and am especially thankful for what SWANA and SCS are today,” stated Tom Conrad.

SWANA recognizes Conrad for over 60 years of significant influence on the waste management and environmental services industry. Conrad, a Founder, Executive Vice President, and Director Emeritus of SCS Engineers, dedicated his career to advancing solid waste management, most notably through the founding of SCS Engineers (Stearns, Conrad, and Schmidt Consulting Engineers) more than 51 years ago.

Tom Conrad worked on a wide range of environmental engineering projects touching almost every aspect of solid waste management throughout his career. As an environmental engineering firm and consultant to the newly created US Environment Protection Agency (EPA), the founders recognized that responsible solid waste management was increasingly important for protecting the environment and the health and safety of the general public.

Leading SCS, he helped the EPA develop the first federal regulations for sanitary landfills, managing and capturing landfill gas, waste sorting protocols, sludge management, and land remediation.

Environmental services, including wastewater management, were always a significant part of SCS services and the waste industry. When new regulatory policies began expanding in the ’80s, SCS’s techniques, technology, and expertise helped a broad range of industries comply with environmental needs and continues today with the firm’s greenhouse gas, landfill technology, renewable energy, remediation, and sustainable materials management programs.

Conrad is also known for hiring and mentoring today’s SCS leaders, many of whom are SWANA leaders, by creating and fostering SCS’s culture encouraging employee participation in industry associations, community, and SCS’s mentorship and leadership programs.

Before his retirement in 2016, Conrad held professional engineering licenses in 24 states. He was a member of SWANA, the American Society of Civil Engineers, the National Waste and Recycling Association, and the Society of American Military Engineers.

He maintains his “work hard – play hard” lifestyle. He is active at SCS, participating in Board of Director meetings and speaking at the Young Professionals Group events and celebrations. While no longer mountain climbing and biking cross-country, he has a vigorous walking, swimming, and biking schedule.

The recent MWEA Conference covered a wealth of other important topics on water management and safety, including this presentation with SCS Engineer’s Remote Monitoring Control specialist, Brett Heist. Brett and Jarod Stuyvesant co-presented “More Than a Pretty Map – GIS Covers Your Assets,” including demonstrations of how the City of Zeeland is using GIS to enhance the efficiency of maintenance and inspection activities and improve the reliability of physical infrastructure throughout its community, leading to increased public safety and financial savings.

Click here to view these demos!

DEMOS: There are some unique methods to plan for capital improvements and streamline data storage and access being implemented in the City of Zeeland. The City has an integrated GIS map for its storm, sanitary, water, and streets, including information about each asset within the system: material, size, inverts, condition, business risk, and even televised inspection videos for some of the storm and sanitary lines.

The GIS maps’s information is used daily by public works and to create a comprehensive capital improvement map that the City uses to plan for 5-year improvements, significantly improving planning and budgeting efficiency while ultimately providing the public with safer infrastructure.

Features include televised inspection videos attached to a respective asset after uploading and accessible with the click of a mouse. Access entire buildings in the same manner as horizontal assets using a 3D online viewer.

The Zeeland Clean Water Plant RAS Building: Using AutoCAD data, the City created a 3D GIS viewer of this building and its assets. Asset information, such as blower and pump sizes and operation and maintenance tasks, are accessible without having to sort through shop drawings and as-builts.

Another example of implementing 3D GIS data like this is for MobileGR who uses a 3D GIS model to store asset data and maintenance tasks for every one of their nine parking ramps in downtown Grand Rapids.

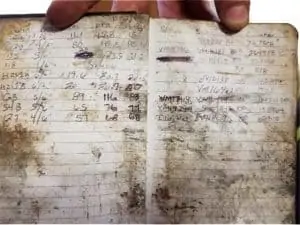

In her first job at SCS Engineers, Joy Stephens worked in a small trailer, consolidating and analyzing data from landfill field techs’ notes, recorded in logbooks they lugged around while navigating the challenging site terrain, then brought to her covered in leachate and mud.

She cross-referenced their detailed, handwritten records with a master list posted on a wall, organized, and methodically examined them. Then she turned them into actionable intel for SCS’s engineers and scientists.

“That was definitely easier said than done. It was a lot of work – a lot of hours to make sure that we were ready for the next day. It struck me that there’s got to be a better way. That we could make collecting and using this valuable information easier for the field staff and OM&M (Operations, Monitoring & Maintenance),” she says.

GIS Supports Wellfield Operations

From that inspiration came a lot of brainstorming, developing, and tweaking what today is a powerful yet user-friendly GIS system that stores and organizes volumes of geographical information in one place and gives users what they need fast to troubleshoot landfill conditions. The customizable application is now used at hundreds of landfills across the country, mainly to support wellfield operations, though it has other landfill system applications.

Field techs enter information onto digital forms using a mobile app and submit the data, uploading it to the cloud. OM&M teams have it in a streamlined format in a couple of minutes and can visualize what they are looking for on maps from a dashboard.

The technology that Stephens was an integral player in launching continues to evolve, and there’s a story behind that evolution.

“In the beginning, I reached out to this brilliant young lady, Brooke Aumann, from the Tampa office, who does a lot of GIS work. I had some GIS experience myself, but more landfill knowledge. I picked her brain so we could set up a digital replacement for the logbooks that zeroed in on exactly what the field techs and project managers needed to support our clients,” says Stephens, an environmental scientist.

Together, the two women created experimental web maps to plot and visualize basic information such as the location of each monitoring point, points requiring the collection of liquid levels, and the status of maintenance tasks at each well. Then they developed digital survey forms with more detailed information and connected those forms to the maps; this enabled end-users to overlay even more data for a holistic snapshot of what goes on at wellfields.

“We tried different configurations of web maps and symbology to depict best what we wanted to convey. We talked about what we needed to symbolize and how we needed to symbolize it. And we discussed possibilities for future developments. We knew much more was possible in terms of what we could collect, how all of these data are connected, and how we could exploit the software to better tackle more complex tasks,” Stephens says.

From maps to interfacing data forms to the next level X-ray vision

“Now we’ve gone a step further. We’re doing 3D well visualizations, which give a kind of Superman X-ray vision subsurface. You are literally looking beneath to the well to get good intel,” Stephens says.

Traversing the World

With undergraduate degrees in Mandarin Chinese and geology and graduate degrees in teaching science and environmental management, Stephens has long loved learning, the environment, and nature.

“When I was young, my parents were missionaries, and I grew up in the most beautiful, pristine, remote areas, like the Solomon Islands and Vanuatu – so unspoiled and lovely.”

It was a sharp contrast to what she would see later when she moved with her young son to China, where she taught math and science. The air quality was poor, and the streets and landscape were inundated with litter.

That experience was the final push that landed the young professional at the foot of a career path she’d considered for some time; environmental sciences. She’d taught it before, but a voice inside her was telling her to pivot and actually start doing the work.

Stephens found her way into a program at a university in Scotland after researching graduate environmental management programs worldwide. At this prestigious learning institution, she first worked with remote sensors and GIS, identifying and addressing “waste crimes,” namely illegal dumping.

Seizing the opportunity to apply her expertise

After graduation, the teacher-turned-scientist took her education and experience back to the United States and SCS Engineers. The company was not foreign to her. By the time she applied, she had made as much a project of vetting employers as she had of scoping out universities. Two draws drew her attention:

“There is the ethos; SCS is genuinely committed to the environment. And the other part that was important to me is SCS is very invested in professional growth and training to foster that growth. I believed that I would have opportunities to move up,” Stephens reflects, recalling when she said yes to the first job working with those logbooks that would be the catalyst to what was to come.

When she came on board, she had to gain practical experience in the solid waste industry and learn the ropes in the field, in addition to her prior experience in renewable energy. In time she had learned her way around landfill gas collection wells, then kept building on that knowledge.

“I asked a ton of questions. Why are we monitoring for this? What constitutes good gas quality? Why is it important to know liquid levels? What is the difference between vacuum and flow? I think asking all these questions, collecting field data myself, and watching what the guys in the field had to do, gave me a good base understanding to help inform how we would capture the right information using GIS. It was a collaborative effort. Brooke worked on many landfill projects and my colleague, Chris Carver, had 16 years of field and project management work. It all came together.”

She later joined the RMC team (Remote Monitoring and Controls), where she received further training in GIS and mastered other skill sets. Today she is a project professional specializing in GIS and drone services.

At home with waste management

The hybrid techie-artist in Stephens comes out when she makes an analogy that tells a little of how her wheels turn.

She grew up playing Legos and now, at almost 40 years old, still builds with them at home with her son.

She approaches the job the same way as when she assembles those sets.

“You know the pieces fit to make something, but it takes creativity to figure out just how to build it and make it as visually pleasing and functional as you can, or to get it to function in different ways. I try to configure and piece together for the best possible design,” she says.

Stephens has married that approach with a desire to be a part of both restoring and protecting the environment. She thinks she’s in the right place to act on that intention.

“I feel like work with waste management and SCS is a way to achieve what I think is so important. We are trying to protect, remediate, and leave conditions better than we found them. That is what being a good steward is all about.”

See Joy Stephens at work in her recent educational presentation for landfill owners and operators. Joy demonstrates technologies to reduce the time to collect, process, and show data.

The EPA’s published clarifications, technical revisions, and new rule versions for the National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) for MSW landfills may feel like alphabet soup right now.

SCS Engineers’ upcoming webinar and open Q/A forum on July 15, 2021, at 1:30 Eastern Time is free and could help keep you informed and on track for compliance by September 27, 2021.

Our panelists will advise on the essential key information, deadlines, and changes to field operations to address during the transition from the old to the new NESHAP and NSPS rules.

• Surface emissions monitoring;

• Wellhead monitoring and corrective action requirements;

• Delegation of authority to the state, local, or tribal agencies for emission standards;

• Applicability of the General Provisions under 40 CFR 63, Subpart A to affected landfills;

• Monitoring data for control devices during startup, shutdown, and malfunctions (SSM);

• Gas collection and control system installation;

• Compliance timing and reporting;

• Open question and answer throughout the webinar.