Learn about SCS Engineers Air Emissions Services

EPA updated its Compliance and Emissions Data Reporting Interface (CEDRI) for the electronic reporting of air emissions under the NESHAP related to MSW landfills. Three new reporting templates were added on October 15, 2024, each linked to its corresponding Excel spreadsheet template. These include the

The Semi-Annual report is the most significant because MSW landfills have 90 days to begin using the Excel template. Reports due January 13, 2025, or any time after that must include this electronic filing.

EPA’s color-coded template provides a bit of instruction.

The gray tab (Company Information) contains general information likely to be unchanged from report to report. After completing the gray tab, you may save the workbook as a site-specific template to use in subsequent reports to limit subsequent data entry.

Complete the green tabs (Certification, CMS Info, Description of Changes, Exceedances, and Number of Exceedances) as appropriate to complete the semi-annual report.

Complete the blue tabs (Deviation Detail, Deviation Summary, CMS Detail, and CMS Summary) if deviations or CMS out-of-control periods or downtime periods occur according to §63.10(e) and as defined in §63.1990.

The orange tabs (Well Expansion, Operational Statements, Site Specific Treatment, Enhanced Monitoring, Bypass CDT Not Operating, and Corrective Action Analysis) cover information required by the semi-annual report requirements of §63.1981(h); be sure to complete the requisite tabs.

Professionals at SCS Engineers will post more guidance but plan to continue preparing our clients’ semi-annual reports as we do now, and completing and submitting this spreadsheet. Please work with your air emissions specialist or project manager, or contact us for support.

Additional Resources:

Join SCS for an unforgettable experience as we delve into the solid waste industry’s latest trends, technologies, and best practices. Network with industry experts, discover innovative solutions and gain valuable insights to enhance your professional growth.

When the modeling and data show differently, landfill owners and operators can more efficiently put controls and solutions in place.

The Rocky Mountain Chapter has reserved hotel rooms to ensure you enjoy a comfortable and memorable experience. These rooms are available at exclusive rates, providing you with both luxury and value. Book now and guarantee your spot. Phone: 1-888-525-1787, or go to www.breckresorts.com.

This Air & Waste Management Association specialty conference is the perfect event to provide an important basis for future development and advancements in the air quality modeling field. It will also provide in-person opportunities for stakeholders and regulators to discuss the challenges and techniques to model ever-tightening air quality standards.

The technical program will include an opening plenary session devoted to invited presentations by EPA’s Office Air Quality Planning and Standards (OAQPS) Air Quality Modeling Group (AQMG). Multiple sessions will cover key modeling topics, and the popular Town Hall Meeting will include an interactive Q&A format with high-level regulators and stakeholders.

Determining actual fugitive landfill gas/methane emissions from the landfill surface is hard to quantify. Drone methane and surface emission monitoring conducted on the landfill surface can determine methane concentrations at receptor points around the landfill surface. These receptor concentrations can be used to run an air dispersion model in reverse to solve for the emission rate of the entire landfill surface. This method also allows you to determine a more accurate control efficiency of the gas collection and control system at the landfill based on landfill gas/methane flow to the combustion device. Want to know more?

Other session topics include:

A revision to AP-42 regarding Municipal Solid Waste (MSW) Landfills was finalized on August 15, 2024. AP-42 is the Compilation of Air Pollutant Emission Factors guidance developed by the U.S. Environmental Protection Agency (EPA) to evaluate air pollution emissions from various sources. EPA drafted new emission factors for the MSW Landfill portion of AP-42 on January 12, 2024 and offered a 60-day public comment period that ended March 12, 2024.

Highlights of this final action include:

For additional information, please contact SCS Engineers, or visit the EPA Air Emissions Factors and Quantification website.

The commercial office sector in cities around the country is facing unprecedented challenges due to high vacancy rates that have been driven by factors including the work-from-home trend and the highest interest rates in almost 20 years. SCS Engineers worked with a panel of experts in the fields of economics, law, architecture, property development, and building sciences to explore the opportunities and challenges of the adaptive reuse of existing commercial buildings into new uses such as residential ones.

The resulting article provides valuable solutions and insight and can be found in Western Real Estate Business at this link: Western Real Estate Business April 2024 Page 20

SCS Engineers provides environmental consulting services for the real estate industry, including asbestos and lead-based paint surveys that are often needed before any building renovations or adaptive reuse. Once asbestos-containing materials or lead-based paint is identified at the building site, abatement activities to remove or mitigate the risks from these materials take place.

SCS monitors these abatement activities with air monitoring and inspections to make sure the removal is conducted according to regulations, and to protect workers and members of the surrounding community from exposure to these harmful chemicals; protecting and rehabilitating these spaces for re-occupancy.

Additional Information:

The U.S. Environmental Protection Agency and the U.S. Department of Energy announced on June 21st that applications are open for $850 million in federal funding for projects that will help monitor, measure, quantify, and reduce methane emissions from the oil and gas sectors. The funding aims to specifically help small oil and natural gas operators reduce methane emissions and transition to available methane emissions reduction technologies, while also supporting partnerships that improve emissions measurement and provide accurate, transparent data to impacted communities.

A competitive solicitation for this funding will enable a broad range of eligible U.S. entities to apply, including industry, academia, non-governmental organizations, Tribes, and state and local governments. This funding opportunity is expected to achieve measurable outcomes for skilled workforce training, community involvement, and environmental justice. Funding applicants are required to submit Community Benefits Plans to demonstrate meaningful engagement with and tangible benefits to the communities in which the proposed projects will be located. These plans must provide details on the applicant’s commitments to community and labor engagement, quality job creation, diversity, equity, inclusion and accessibility, and benefits to disadvantaged communities.

The primary objectives of this funding opportunity announcement are to:

1. Help small operators significantly reduce methane emissions from oil and natural gas operations, using commercially available technology solutions for methane emissions monitoring, measurement, quantification, and mitigation.

2. Accelerate the repair of methane leaks from low-producing wells and the deployment of early-commercial technology solutions to reduce methane emissions from new and existing equipment such as natural gas compressors, gas-fueled engines, associated gas flares, liquids unloading operations, handling of produced water and other equipment leakage.

3. Improve communities’ access to empirical data and participation in monitoring through multiple installations of monitoring and measurement technologies while establishing collaborative relationships between equipment providers and communities.

4. Enhance the detection and measurement of methane emissions from oil and gas operations at regional scale, while ensuring nationwide data consistency through the creation of collaborative partnerships. These partnerships will span the country’s oil and gas-producing regions and draw in oil and natural gas owners and operators, universities, environmental justice organizations, community leaders, unions, technology developers, Tribes, state regulatory agencies, non-governmental research organizations, federally funded research and development centers, and DOE’s National Laboratories.

Additional Resources:

1. Read more details of this funding opportunity.

3.GHG Monitoring, Control, Verification, Reporting

The transition toward sustainable manufacturing represents a pivotal change in how businesses approach production, blending environmental care with economic viability and social good. This evolution is motivated by an understanding that sustainable practices limit environmental harm, promote economic prosperity, spur innovation, and offer a competitive edge. Leading corporations, including BMW, Procter & Gamble, and Nestlé, have demonstrated the practicality and profitability of incorporating sustainability into their operations.

Incorporating sustainability into manufacturing requires a careful balance between initial costs and long-term benefits, focusing on increasing efficiency, fostering innovation, and engaging with stakeholders. These strategies are key to improving financial performance and maintaining a competitive position in the market.

The shift towards sustainable manufacturing is motivated by numerous factors, highlighting its advantages for the corporate world and the environment. Optimizing the consumption of raw materials, energy, and water slashes production expenses significantly. Practices aimed at environmental stewardship typically result in reduced waste and heightened efficiency in energy use, positively impacting a company’s profit margins. Embracing these sustainable practices allows manufacturers to alleviate the risks of fluctuating raw materials and energy costs. For instance, incorporating recycled materials can stabilize expenses and reduce vulnerability to market changes.

Firms dedicated to environmental stewardship are poised to attract investments from funds and investors that value sustainability, which is crucial for funding innovations, business expansion, and product and process quality enhancements. Additionally, financial incentives like tax reductions or grants provided by governments and international entities further support the economic feasibility of integrating new sustainable technologies or methodologies.

Sustainability also paves the way to unlocking new markets and customer segments, responding to surging demand for eco-friendly products. This demand can enable companies to command higher prices, foster greater customer loyalty, and penetrate markets where environmental stewardship is either a regulatory mandate or a consumer expectation.

The movement towards sustainable manufacturing has inspired numerous companies across various sectors to innovate and implement practices that reduce environmental impacts while bolstering economic performance. Some examples include:

BMW Group – Sustainable Automotive Manufacturing The BMW Group has incorporated sustainability into every aspect of its production process. From using renewable energy sources to power its manufacturing plants to implementing recycling and water conservation practices, BMW has set a high standard for sustainability in the automotive industry. For example, the company’s Leipzig plant powered by wind energy utilizes lightweight materials to improve vehicle fuel economy, demonstrating BMW’s comprehensive approach to sustainable manufacturing.

Procter & Gamble (P&G) – Eco-Friendly Consumer Products Procter & Gamble (P&G), a major player in the global consumer goods industry, has fully integrated sustainability into its business approach. Through its Ambition 2030 initiative, P&G endeavors to catalyze positive environmental and societal change while generating value for the company and its consumers. This commitment entails reducing greenhouse gas emissions, transitioning to 100% renewable electricity procurement, and eliminating manufacturing waste sent to landfills across its worldwide network of production facilities.

Nestlé – Reducing Environmental Footprint Nestlé, the world’s largest food and beverage company, has committed to making 100% of its packaging recyclable or reusable by 2025 and to reduce its net greenhouse gas emissions to zero by 2050. The company focuses on improving the environmental performance of its products through design, sourcing sustainable materials, and innovating in waste management practices. Nestlé’s efforts also extend to water efficiency and stewardship, recognizing the critical importance of water conservation in its operations.

Companies offering sustainability solutions to manufacturers are leveraging innovative technologies and strategic approaches to address environmental stewardship challenges, enhance operational productivity, and drive market competitiveness. For example:

Honeywell demonstrates its commitment to sustainability through a wide range of solutions that target various aspects of manufacturing operations, from energy reduction to circular economy practices. The company’s solutions span circular economy initiatives, environmental transformation, energy evolution, and resiliency and accountability, highlighting their broad approach to addressing the manufacturing sector’s sustainability challenges.

The Efficiency Network (TEN) focuses on next-generation building energy efficiency by developing, designing, engineering, financing, and installing cost-effective, energy-saving retrofit projects. Their unique approach combines process automation with industry expertise to revolutionize how energy performance projects and customer relationships are managed. By prioritizing sustainability, TEN aims to reduce energy and operating expenses, lower maintenance costs, and enhance its reputation and employee morale.

Hitachi has positioned itself at the forefront of fostering eco-friendly manufacturing by developing and deploying innovative digital solutions. These innovations empower producers to streamline their operations, diminish energy use, and reduce their environmental impact, leading to greener manufacturing practices. A prime example is the Lumada Manufacturing Insights platform, which has been instrumental for businesses like Logan Aluminum. This tool facilitates the creation of operations based on data analytics, improving supply chain transparency, employing predictive analytics, and advancing intelligent factory capabilities. The result is an uplift in operational performance, minimized equipment downtime, and a significant step towards achieving environmental sustainability by making the manufacturing process more resource-effective and less demanding of natural resources.

Environmental consultants are pivotal in helping manufacturing companies navigate the complexities of sustainability. By offering strategic guidance, performance improvement insights, and communication and reporting strategies, these consultants enable businesses to effectively align their operations with sustainable practices.

The most effective planning frequently comes from environmental consultants who excel in developing sustainable solutions, with a particular focus on alternative sustainability elements. They offer expert advice and have the engineers and scientists to turn solutions into tangible results. These consultants play a crucial role in bridging sustainability gaps between plans and achievements, ensuring that strategies are environmentally friendly but also practical and implementable. They can provide third-party verification of sustainability efforts and credits related to waste reduction and resource management. Highly experienced environmental firms are in high demand for their ability to manage heavy manufacturing processes that produce wastewater, delivering effective treatment or disposal solutions for liquid wastes.

SCS Engineers, for instance, offers comprehensive services that assist companies in understanding their environmental impacts, identifying areas for improvement, and embedding environmental stewardship into their business strategies. These tailored services reduce risks, optimize environmental footprints, and enhance innovation for a competitive edge.

Consultants advocate practical sustainability measures, including optimizing biofuel use, decreasing pollution, engaging in time-saving practices, energy efficiencies, recycling, and reducing waste production. For example, switching to renewable energy sources, conducting energy audits, and investing in energy-efficient technology can significantly lower carbon footprints and operational costs.

Likewise, implementing pollution prevention practices, using eco-friendly materials, and engaging in recycling and closed-loop manufacturing are vital steps toward minimizing environmental impact and fostering sustainable growth.

Environmental consultants offer the expertise and tools necessary for manufacturing companies to achieve their environmental stewardship goals, highlighting a clear path towards more responsible and efficient manufacturing practices.

For companies to progress in their sustainability journey, they integrate sustainability comprehensively and systematically across all business operations, moving beyond isolated efforts. While enhancing efficiency and minimizing risks are crucial, pursuing sustainability offers competitive advantages, innovation opportunities, and revenue growth potential.

By employing innovation and strategic foresight, businesses can surpass basic compliance and proactively address upcoming challenges and opportunities, adopting a forward-looking approach that contemplates their operations’ long-term environmental and societal implications.

The drive towards sustainable manufacturing is essential in corporate production approaches, marrying environmental stewardship with economic and social advantages. This transition, led by companies like BMW, Procter & Gamble, and Nestlé, proves sustainable manufacturing is viable and profitable.

Embracing sustainability is not merely about meeting environmental standards but capturing opportunities for growth, innovation, and leadership in the global market. The successful implementation of sustainability strategies demonstrates that businesses can thrive while contributing positively to the planet’s future. The collective efforts of these leading companies offer a promising path toward a more sustainable, efficient, and inclusive industrial world.

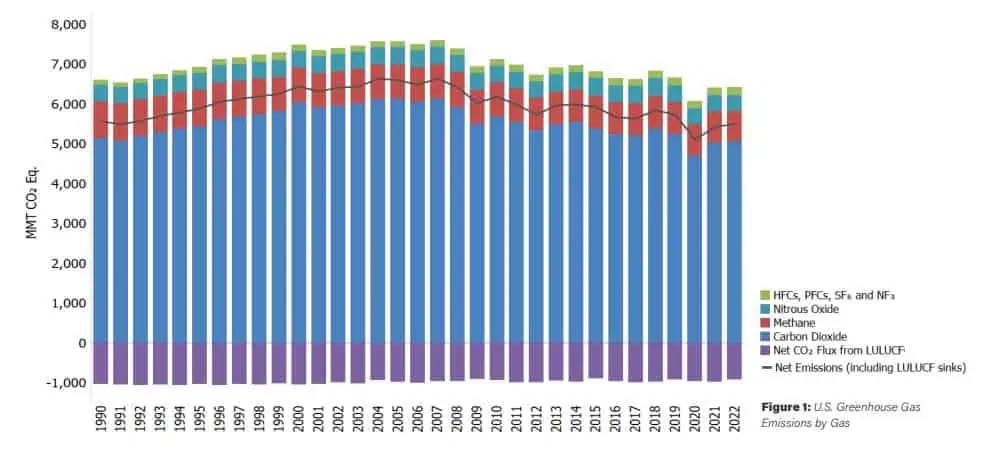

On April 11, 2024, the U.S. Environmental Protection Agency (EPA) released its annual Inventory of U.S. Greenhouse Gas Emissions and Sinks (GHG Inventory), presenting a national-level overview of annual greenhouse gas emissions from 1990 to 2022.

The GHG inventory identifies and quantifies anthropogenic sources and sinks of greenhouse gas emissions and removals, which is essential for quantifying and qualifying data used to address climate change and measure the impact of environmental solutions and sustainability plans. In this context, the term “anthropogenic” refers to greenhouse gas emissions and removals that are a direct result of human activities or are the result of natural processes that have been affected by human activities.

The GHG Inventory covers seven key greenhouse gases: carbon dioxide, methane, nitrous oxide, hydrofluorocarbons, perfluorocarbons, sulfur hexafluoride, and nitrogen trifluoride. In addition to tracking U.S. greenhouse gas emissions, the Inventory calculates carbon dioxide removed from the atmosphere through carbon uptake in forests and other vegetation.

Greenhouse gases are emitted and reported across five economic sectors: transportation, electric power (electricity generation), residential/commercial (homes and businesses), industry, and agriculture. Emissions from commercial/residential and industrial activities account for a much larger share of U.S. greenhouse gas due to their proportionately larger share of electricity use in these sectors (e.g., heating, ventilation, and air conditioning; lighting; appliances; powering industrial machinery).

Transportation activities were the largest source (28 percent) of total U.S. greenhouse gas emissions in 2022. From 1990 to 2022, transportation CO2 emissions from fossil fuel combustion increased by 19 percent, largely due to increased travel demand.

The electric power sector accounted for 25 percent of U.S. greenhouse gas emissions in 2022. Emissions from this sector have decreased by approximately 16 percent since 1990, and the carbon intensity of the sector, in terms of emissions (CO2 Eq.) per QBtu input, has decreased by 28 percent. Total electric power generation increased by 3 percent in 2022, while electric power-related emissions decreased by less than 1 percent due in part to a decrease in coal consumed to produce electricity and an increase in renewable generation.

The commercial and residential sectors accounted for 7 and 6 percent, respectively, of total U.S. greenhouse gas emissions in 2022, excluding indirect emissions from electricity end-use. Emissions from these sectors are primarily from building-related activities such as heating and cooking and have increased since 1990. Emissions from commercial and residential buildings also increase substantially when emissions from electricity end-use are included because the building sector uses 75 percent of the electricity generated in the U.S. for heating, ventilation, air conditioning, lighting, and appliances (NREL 2023). Total residential and commercial greenhouse gas emissions, including direct and indirect emissions, have decreased by 1 percent since 1990.

The industrial sector accounted for 23 percent of U.S. greenhouse gas emissions in 2022, excluding indirect emissions from electricity end-use. If indirect emissions from electricity use are distributed to the industrial end-use sector (e.g., powering equipment and industrial buildings), industrial activities account for 30 percent of U.S. greenhouse gas emissions. Since 1990, emissions from industry have declined by 16 percent. Shifts in industrial output away from energy-intensive manufacturing products to less energy-intensive products have had a significant positive impact on industrial emissions.

Agriculture accounted for about 10 percent of U.S. greenhouse gas emissions in 2022 and includes sources such as livestock enteric fermentation and manure management, N2O emitted from managed agricultural soils from fertilizers and other management practices, and fossil fuel combustion from agricultural equipment. Indirect emissions from electricity in the agricultural sector are about 5 percent of sector emissions. In 2022, agricultural soil management was the largest source of N2O emissions, and enteric fermentation was the largest source of CH4 emissions in the U.S. There are several strategies for reducing CH4 emissions from enteric fermentation and manure management, including anaerobic digestion and liquid-solid separation, which the sector is embracing.

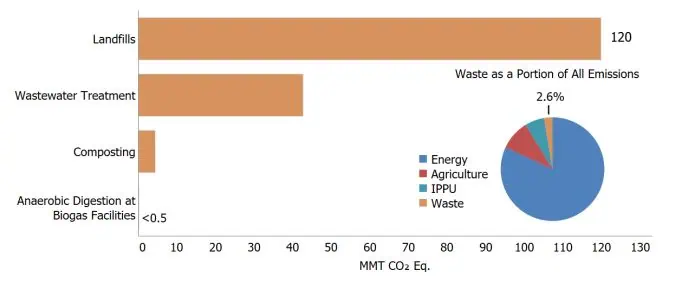

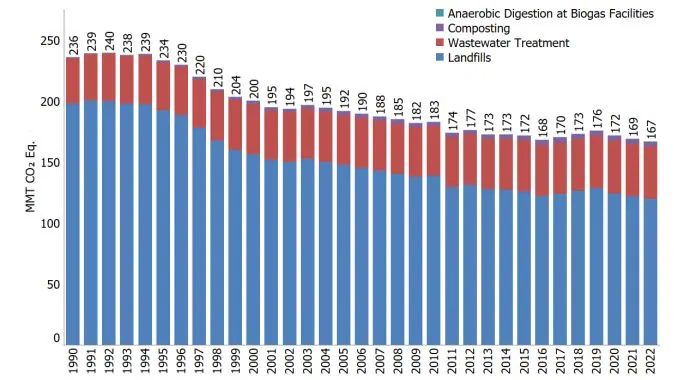

A summary of greenhouse gas emissions from the Waste sub-sector is below. In 2022, waste activities generated emissions of 166.9 MMT CO2 Eq., or 2.6 percent of total U.S. greenhouse gas emissions.

Methane generation and emissions from landfills are a function of several factors. Each landfill has unique characteristics, but emissions from MSW landfills accounted for approximately 84 percent of total landfill emissions (100.9 MMT CO2 Eq.), while industrial waste landfills accounted for the remainder (18.9 MMT CO2 Eq.). Nationally, there are significantly fewer industrial waste landfills than MSW landfills, contributing to the lower national estimate of CH4 emissions for industrial waste landfills.

The annual amount of MSW generated and disposed of in MSW landfills varies annually and depends on several factors (e.g., the economy, consumer patterns, recycling, composting programs, and inclusion in a garbage collection service).

The estimated annual quantity of waste placed in MSW landfills increased by 10 percent from approximately 205 MMT in 1990 to 226 MMT in 2000, then decreased by 11 percent to 202 MMT in 2010, and then increased by 7 percent to approximately 217 MMT in 2022.

Emissions decreased between 1990 and 2022 largely because of increased use of landfill gas collection and control systems, closure of older landfills, better management practices, and increased organics diversion through state and local policy and regulations.

Biogas, Anaerobic Digestion, Renewable Natural Gas and Energy Systems

Carbon Sequestration & Deep Well Injection

CCR and Electric Utilities

Clean Air Act

Facility Energy Management

Greenhouse Gas Monitoring, Control, Inventory

Landfill Gas and LFGE

Liquids Management – Wastewater and Leachate

Material Recovery Facilities and Transfer Stations

Oil and Gas Exploration and Production

Organics Management, Composting

SCS Remote Monitoring and Control® (Emissions Tracking)

SCSeTools® (LFG Tracking)

Solid Waste Planning, Sustainable Materials Management

Sustainable Solutions Planning

Partial reprint of EPA’s Announcement dated January 11, 2024

WASHINGTON – The U.S. Environmental Protection Agency on Thursday announced a proposal to strengthen Clean Air Act standards for large facilities that burn municipal solid waste. If finalized, the updated standards would reduce emissions of nine pollutants, including smog- and soot-forming sulfur dioxide and nitrogen oxides, by approximately 14,000 tons per year, improving air quality for overburdened communities living near these facilities. These proposed standards reflect current technologies available to control pollution in a cost-effective fashion.

The proposed standards would apply to 57 facilities with 152 units that have the capacity to combust more than 250 tons per day of municipal solid waste. Nearly 4 million Americans live within 3 miles of these large facilities, which are disproportionately located in low-income communities and communities of color.

The proposed standards are based on emission levels achieved by the best controlled and lower-emitting sources, and limit emissions of nine pollutants: particulate matter, sulfur dioxide, hydrogen chloride, nitrogen oxides, carbon monoxide, lead, cadmium, mercury, and dioxins/furans.

The Clean Air Act requires EPA to evaluate these standards every five years in order to take into account developments in pollution control technologies and techniques. EPA last revised these standards in 2006.

After accounting for compliance costs of the rule, EPA estimated the net present value of health benefits from the proposed rule, due to reductions in particulate matter and ozone alone, to be up to $14 billion over 20 years. Reductions of mercury, lead, and other hazardous air pollutants required by the proposal are expected to result in additional unquantified economic and public health benefits.

EPA will accept comment on the proposal for 60 days after publication in the Federal Register. EPA will hold an informational webinar and will announce details on its website shortly.

Additional Resources:

A Brief Regulatory History in California

On June 22, 2023, the California Air Resources Board (CARB) approved amendments to the Greenhouse Gas Emission Standards for Crude Oil and Natural Gas Facilities (Oil and Gas Methane Regulation). On November 2, 2023, CARB proposed additional modifications for public review. The public comment period ends November 17, 2023.

The Oil and Gas Methane Regulation was originally adopted in 2017 to reduce emissions by requiring:

Then in 2018, this regulation was included in California’s State Implementation Plan (SIP) to address VOC control requirements from the US EPA’s 2016 Control Techniques Guidelines (CTG) for the Oil and Natural Gas Industry. In 2022, the US EPA reviewed the SIP submittal and developed a list of deficiencies. Therefore, the Oil and Gas Methane Regulation was amended to address deficiencies and avoid sanctions under the Clean Air Act.

The Oil and Gas Methane Regulation was also amended so that CARB can use remote monitoring data from approved technologies to detect methane emission plumes and then mandate correction actions.

For example, it is anticipated that CARB will start receiving satellite data in late 2023. Once notified by CARB of a remotely detected methane plume, a facility will need to conduct inspections and repairs as well as submit reports as required by the amended regulation.

Finally, additional amendments were made to clarify the regulatory language based upon CARB’s experience with implementing the regulation over the past five years. Based on this summary in California, there is more movement in other states and not just for oil & gas facilities, but many more.

What to Expect in 2024 – Nationwide

The use of satellites and Carbon Mapper are game changers. Carbon Mapper is a nonprofit entity that started flying key mission sectors and not just landfills or waste management sites. They target energy production facilities, agriculture, particularly livestock coal, mining operations, and oil and gas facilities.

The purpose is to track strong methane emissions, obviously. But the kicker is that the data is free and open to the public in the form of a methane plume overlaid on a map. The imagery usually has estimated emissions rates. Many facility owners, managers, and businesses are not aware of these monitoring events, let alone the accessibility and transparency via the Internet to the public.

Our clients reach out to us knowing that SCS has a robust drone and monitoring program – we can fly the sites and locate leak sources in hours. By using drones, our clients could respond quickly and we could identify current limitations of satellite technology for them. The resolution at a satellites high altitude does not detect and localize leak sources, but remote monitoring and control does.

Many of our clients take a proactive approach now of reoccurring drone methane inspections. We can identify areas of concern before the site is flown by manned aircraft or capture by satellites, and mitigate any potential issues ahead of making headline news. The benefit for implementing long-term operational enhancements and efficiencies prevents odors, complaints, nuisance suits, and negative headlines.

There are complementary technologies that work together, satellites, planes, drones, robot-dogs, automated wellheads, and the traditional boots on the ground. The key is combining the ones that work together to provide a more holistic view of of what’s going on at your facility. That’s where the ROI is and provides a single source to combine all data elements – so no need to move back and forth between software systems.

Questions? Contact our professionals at for immediate assistance.

Additional GHG Emissions Resources