Green hydrogen recently got a big boost when the administration enacted the Inflation Reduction Act (IRA) law on August 16, 2022. The IRA provides $369 billion in funding for climate change and energy security initiatives. It includes a wide range of tax incentives and tax credits for clean energy — including tax benefits for the production, storage, and utilization of hydrogen.

Electricity from renewable sources such as wind, solar, or hydro generates green hydrogen. This article evaluates the feasibility of hydrogen as green energy from production, transportation, storage, infrastructure investment, and environmental impact aspects.

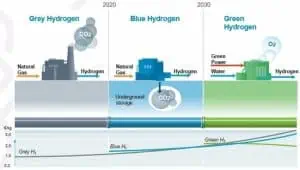

Using renewable electricity, splitting water into hydrogen and oxygen with electrolysis produces green hydrogen. Blue hydrogen is when natural gas is split into hydrogen and CO2 either by Steam Methane Reforming or Auto Thermal Reforming, with the CO2 captured and then stored. Grey hydrogen is produced by a similar process to blue hydrogen, splitting natural gas into Hydrogen and CO2, with the CO2 released into the atmosphere.

The adoption of hydrogen as a fuel will advance over the next decade. Hydrogen can produce various synthetic fuels like e-kerosene, e-methanol, and e-gasoline, which support the decarbonization of the aviation, shipping, and transportation industry.

Air permitting issues will not likely be significant at green hydrogen plants because there are no significant air emission sources at an electrolysis plant. However, dispersion air issues are associated with venting hydrogen into the atmosphere during startup, shutdown, or malfunction events.

Hydrogen use can reduce GHG emissions, meet the challenges of balancing intermittent renewables, and reduce air pollution in cities. Zero-carbon fuels like hydrogen do not contain carbon atoms and therefore do not emit CO2 when combusted, unlike fossil fuels.

There are, however, environmental issues associated with hydrogen combustion for power generation. A common assumption is that hydrogen is a clean-burning fuel, free from emissions of harmful air pollutants. While hydrogen as a fuel does not emit greenhouse gases, a combustion unit uses ambient air to supply the oxygen in the fuel combustion process. This air contains nitrogen that, in the presence of heat and oxygen, forms oxides of nitrogen (NOx). NOx emissions are highly regulated air pollutants by federal, state, and local environmental agencies.

Hydrogen combustion produces higher NOx emissions than natural gas combustion. Hydrogen is lighter, burns hotter, and carries one-third the heating value on a volumetric basis compared to natural gas. Because it burns hotter, NOx emissions are higher. This increase in NOx emissions will likely trigger additional air permitting complications for existing units and challenges in the design and operation of new units. Combustion turbines that burn 100% hydrogen will have to consider NOx emissions.

Various states and entities in the public and private sectors have come together to develop proposals for the regional clean hydrogen hubs program. There are ten regional clean hydrogen hubs across America. These hubs intend to create networks of hydrogen producers, consumers, and local connective infrastructure to advance the use of hydrogen. It will take time to build a national hydrogen delivery infrastructure, and infrastructure needs and resources will vary by region and type of market.

The U.S. Gulf Coast is a leader in energy production, processing, and exports. Many skills and technologies today are ideally suited to be repurposed for green hydrogen in the future. Arizona, Texas, and Louisiana are ideally suited to produce green hydrogen because of the advancement of renewable energy combined with energy infrastructure.

However, there are some hurdles to overcome. For example, moving green hydrogen by pipeline would presumably fall under Pipeline and Hazardous Materials Safety Administration’s existing pipeline safety regulations, primarily designed for natural gas pipelines. Many existing pipelines could not handle green hydrogen because of hydrogen’s unique properties. Hydrogen’s small molecular size allows it to penetrate the steel of pipelines operated at high pressures through a process known as absorption. Absorption can result in the embrittlement of certain high-strength steel and pipeline welds. Existing natural gas and hazardous liquid pipelines were not constructed with hydrogen transmission in mind and are likely to include materials or welds vulnerable to absorption and embrittlement. Therefore, converting many existing pipeline systems and components to hydrogen service may not be possible or economically attractive.

Hydrogen is transportable by pipeline or over the road as a pressurized gas or in cryogenic liquid tanker trucks. Key challenges to hydrogen delivery include reducing cost, increasing energy efficiency, maintaining hydrogen purity, safety, and minimizing hydrogen leakage.

The H2 molecule is exceedingly small and difficult to contain, so it is still largely unknown how much H2 will leak in future processes. H2 emissions will occur due to venting, purging, and incomplete combustion. Currently, no commercially available sensors can detect hydrogen emissions at levels well below the threshold for hydrogen gas flammability required to characterize emissions in the open.[1]

H2 emissions may have a significant indirect radiative forcing by aggravating the concentration of other GHG gases in the atmosphere[2]. The release of hydrogen increases the concentration of other greenhouse gases like methane, water vapor, and ozone, contributing to global warming.

H2 emissions are far from being climate neutral. Recent research has affirmed that the warming effects from hydrogen emissions are consequential. Hydrogen’s indirect warming effects are twice as high as previously recognized[3] due to the inclusion of stratospheric effects not considered until recently[4].

As mentioned earlier, burning hydrogen can lead to the thermal formation of nitrogen oxides. The amount and dangers of it are under investigation. It may be a challenge to achieve strict NOx limits in the future.

Over the next few years, multiple hydrogen projects will seek consent for planning permission and environmental permits. Some of the environmental laws pertaining to the construction of a green hydrogen plant include the following:

State regulations will also apply; for example, in Texas, specific permitting requirements include:

An Environmental Assessment (EA) will be required for those projects for which the significance of impacts is not clearly established. If more analysis is necessary to determine whether impacts are significant, an Environmental Impact Statement (EIS) will need to be prepared. Actions that would significantly affect the natural, cultural, and human environment require the preparation of an EIS. EIS projects tend to be complex projects with substantial impacts on various environmental resources.

A company may be required to perform an environmental assessment or environmental impact assessment when federal control, authorization, or funding is required. Requirements could include many of the National Environmental Policy Act (NEPA) requirements, such as wetlands delineation, habitat assessment, archeological surveys, cultural resources surveys, federal and state listed threatened and endangered species, vegetation resources, soils, and geology.

Both processes require a significant amount of time to complete, three months for a simple EA and six months to 2 years for an EIS.

Because water is necessary to create green hydrogen, groundwater is a major concern in the southwest. Electrolysis breaks down water into constituent elements, which needs to be purified. Most industrial water purification processes require, at minimum, a ratio of 2:1 wastewater to pure water, effectively doubling the amount of water required. This means each ton of green hydrogen could require up to 18 tons of water, and not all can be recycled.

Local groundwater supplies are the most convenient supply. However, states such as Arizona and Texas have Groundwater Management Areas created to conserve, preserve, protect, recharge, and prevent waste of groundwater and groundwater reservoirs or their subdivisions. These areas also help control subsidence caused by water withdrawal from those groundwater reservoirs or their subdivisions.

For example, Arizona’s areas with heavy reliance on mined groundwater are identified and designated as Active Management Areas (AMAs). The five AMAs (Prescott, Phoenix, Pinal, Tucson, and Santa Cruz) are subject to regulation pursuant to the Groundwater Code. In Texas, there are sixteen groundwater management areas. All groundwater conservation districts are part of at least one groundwater management area.

State and local regulations will control withdrawals and uses of groundwater within their jurisdictions.

H2 containment may remain an issue even as technologies progress. Safe storage and transportation are the biggest barriers preventing the widespread adoption of hydrogen energy. The current way of storing hydrogen is in a high-pressure tank or by cooling the gas to a liquid form. Both require large amounts of energy and hazardous processes and chemicals.

Some green hydrogen projects may include a salt cavern storage component as they provide massive storage capacity. Salt caverns could provide injection and withdrawal cycles to meet the needs of the hydrogen market. Most, but not all, of the existing underground natural gas salt cavern facilities in the United States are in the Gulf Coast States. However, high hydrogen diffusivity and bacterial activity can disturb the cavern impermeability and the purity of the stored gas[5].

Depleted gas reservoirs are the most “viable choice due to economic factors, its wide geographical distribution, as well as its proven technical credibility based on the existing natural gas storage facilities.”[6] The injection strategy, reservoir features, quality, and operational parameters significantly impact gas storage in depleted reservoirs.

Green hydrogen currently costs three times as much as natural gas in the U.S. Green hydrogen can be quite expensive to produce and require significant capital investment. Green hydrogen production costs have traditionally been much higher than other forms of hydrogen. Electricity input accounts for much of the green hydrogen production cost, but falling renewable power costs will bridge the gap. Cost reductions will depend on improving the electrolyzer unit’s capital cost and efficiencies and the system’s balance. Prices of electrolyzers are coming down as manufacturing scales up.

Various governments have made substantial investment commitments, including the DOE’s $8 billion program to develop regional clean hydrogen hubs, H2Hubs, as part of the Bipartisan Infrastructure Law. Six to ten regional clean hydrogen hubs will be created across America to create networks of hydrogen producers, consumers, and local connective infrastructure to accelerate the use of hydrogen. Private industry and investors will need to make consequential investment decisions to broaden the green hydrogen value chain.

Deployment of a hydrogen infrastructure constitutes one of the most challenging tasks due to the complexity and large scope of energy sources and technological issues. Integrating renewable energy production and green hydrogen facilities is strategically important since the investment in renewable generation and storage solutions will be massive and complicated.

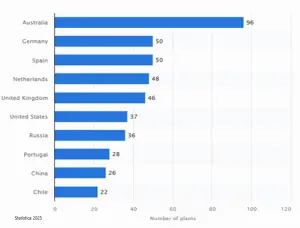

Despite the challenges, green hydrogen will likely be in substantial use over the next five to ten years, especially in Europe and Australia. More and more countries, regions, and companies are committing to green hydrogen as a long-term strategy. As with all renewable energy, innovations in hydrogen-related technologies and their alternatives are expected to arrive in the coming years, which may influence the competitiveness of hydrogen in numerous applications.

[1] Ocko, I. B. & Hamburg, S. P. Climate consequences of hydrogen emissions. Atmos. Chem. Phys. 22, 9349–9368 (2022).

[2] Ocko, I. B. & Hamburg, S. P. Climate consequences of hydrogen emissions. Atmos. Chem. Phys. 22, 9349–9368 (2022).

[3] Paulot, F., Paynter, D., Naik, V., Malyshev, S., Menzel, R., and Horowitz, L. W.: Global modeling of hydrogen using GFDL-AM4.1: Sensitivity of soil removal and radiative forcing, Int. J. Hydrogen Energy., 46, 13446–13460, https://doi.org/10.1016/j.ijhydene.2021.01.088, 2021. Warwick, N., Griffiths, P., Keeble, J., Archibald, A., Pyle, J., Shine, K.: Atmospheric implications of increased Hydrogen use, Department for Business, Energy and Industrial Strategy, https://www.gov.uk/government/publications/atmosphericimplications-of-increased-hydrogen-use, 2022)

[4]Derwent, R. G., Stevenson, D. S., Utembe, S. R., Jenkin, M. E., Khan, A. H., and Shallcross, D. E.: Global modelling studies of hydrogen and its isotopomers using STOCHEM-CRI: Likely radiative forcing consequences of a future hydrogeneconomy, Int. J. Hydrogen Energy., 45, 9211–9221, https://doi.org/10.1016/j.ijhydene.2020.01.125, 2020.

[5] Compendium of Hydrogen Energy, Volume 2: Hydrogen Storage, Distribution and Infrastructure, M. Panfilov, Chapter 4 – Underground and pipeline hydrogen storage, 2016

[6] Hydrogen storage in depleted gas reservoirs: A comprehensive review, Muhammed et al, December 2022.